Optical fiber angle sensor for measuring structural angles

An angle sensor and optical fiber technology, applied in the field of optical sensors, can solve the problems of increased control difficulty, susceptibility to interference, failure to meet requirements, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe the present invention below in conjunction with specific embodiment:

[0015] This embodiment is an optical fiber angle sensor applied to a joint of an exoskeleton robot to measure the angle of a human joint. In this embodiment, the optical fiber angle sensor is installed at the knee joint of the human body.

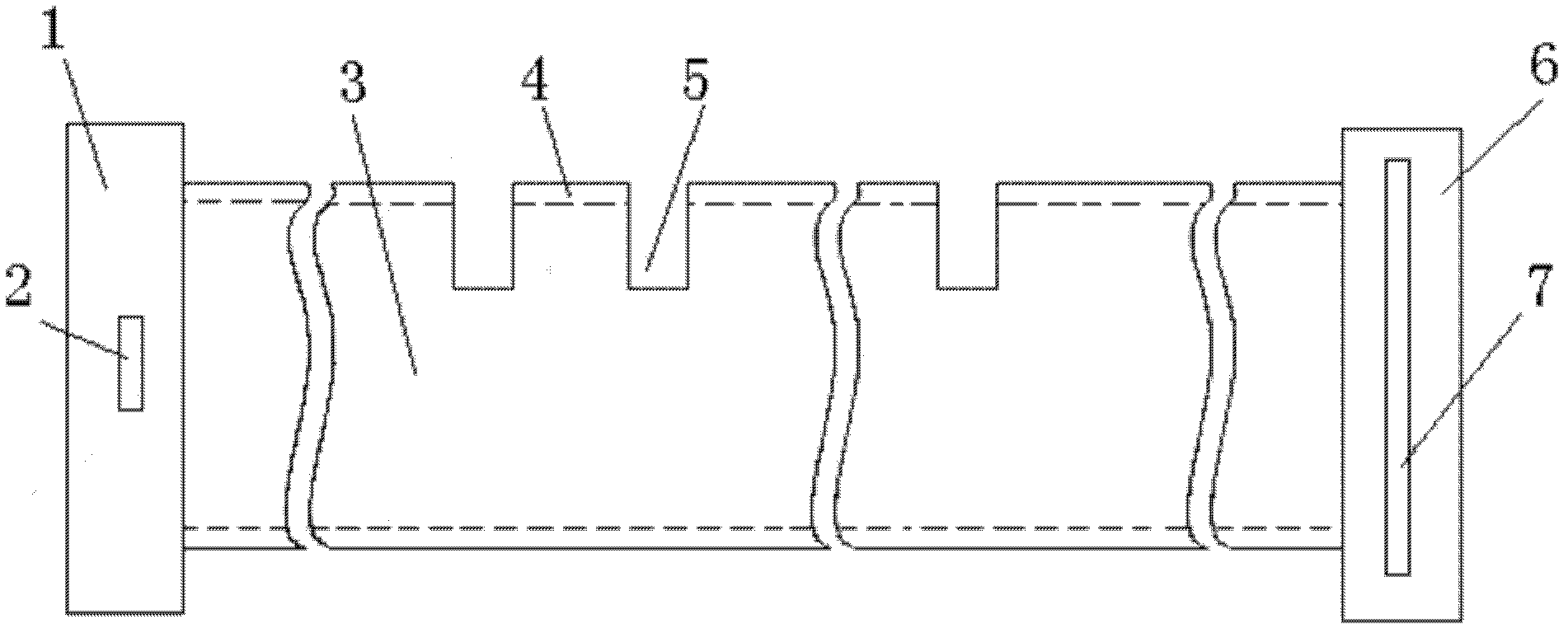

[0016] The fiber optic angle sensor in this embodiment includes a special optical fiber, a light emitting component 2 and a light receiving component 7 . The special optical fiber is in the shape of a wire. The special optical fiber includes a special optical fiber core 3 and a special optical fiber cladding 4. The diameter d1 of the special optical fiber core is 100 microns, and the outer diameter d2 of the special optical fiber cladding is 140 microns. The special optical fiber core is made of thermosetting acrylic resin The special optical fiber cladding is made of fluororesin (PEP) and integrally formed with the special optical fiber core.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com