Natural apple essence and preparation method thereof

An apple flavor and apple technology, which is applied in food preparation, tobacco, tobacco and other directions, can solve problems such as lack of natural flavor products, and achieve the effects of good effect, improved food quality and strong natural feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

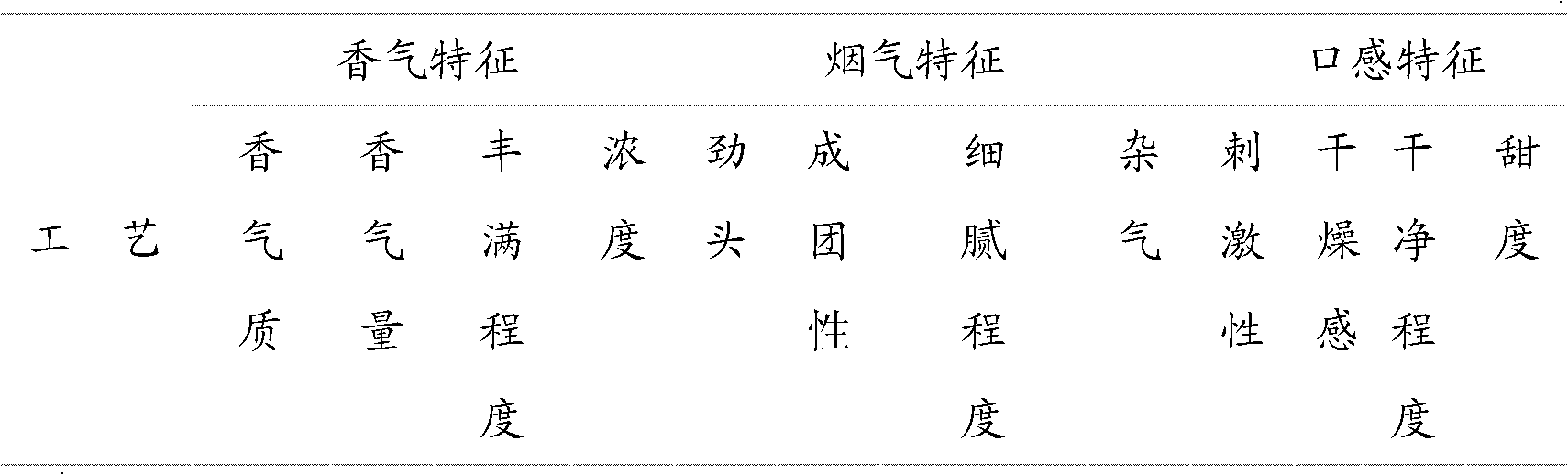

Image

Examples

Embodiment 1

[0012] (1) Weighing 100 kilograms of fresh apples, inspecting, washing, and crushing the raw apples; then squeezing the juice, filtering the juice to obtain clear liquid, and using a vacuum concentration device to concentrate the clear liquid to a density of 1.120 to obtain an apple concentrate;

[0013] (2) The apple concentrate is prepared and modified, and prepared according to the following parts by mass: apple juice concentrate 12kg; trans-2-hexenol 0.1kg; trans-2-hexenal 0.4kg; trans-2-hexenoic acid 0.02kg; caproic acid 0.2kg; 1% ethyl acetoacetate 2kg; acetic acid 0.03kg; hexanal 0.3kg; acetal 0.05kg; lactic acid 0.2kg; California lemon oil 0.1kg; 0.02kg; leaf alcohol 0.1kg; ethyl butyrate 0.5kg; isoamyl acetate 0.5kg; benzaldehyde 0.3kg;

[0014] The above blending process is a relatively common mixing and stirring process. After weighing each raw material according to the corresponding amount, add it to the blending tank and stir for half an hour, then check and put i...

Embodiment 2

[0024] (1) Weighing 100 kg of fresh apples, inspecting, washing, and crushing the raw apples; then squeezing the juice, filtering the juice to obtain clear liquid, and using a vacuum concentration device to concentrate the clear liquid to a density of 1.050 to obtain an apple concentrate;

[0025] (2) The apple concentrate is prepared and modified, and prepared according to the following parts by mass: apple juice concentrate 12kg; trans-2-hexenol 0.1kg; trans-2-hexenal 0.4kg; trans-2-hexenoic acid 0.02kg; caproic acid 0.2kg; 1% ethyl acetoacetate 2kg; acetic acid 0.03kg; hexanal 0.3kg; acetal 0.05kg; lactic acid 0.2kg; California lemon oil 0.1kg; 0.02kg; leaf alcohol 0.1kg; ethyl butyrate 0.5kg; isoamyl acetate 0.5kg; benzaldehyde 0.3kg;

[0026] The above blending process is a relatively common mixing and stirring process. After weighing each raw material according to the corresponding amount, add it to the blending tank and stir for half an hour, then check and put it into ...

Embodiment 3

[0036] (1) Weighing 100 kilograms of fresh apples, inspecting, washing, and crushing the raw apples; then squeezing the juice, filtering the juice to obtain clear liquid, and using a vacuum concentration device to concentrate the clear liquid to a density of 1.250 to obtain an apple concentrate;

[0037] (2) The apple concentrate is prepared and modified, and prepared according to the following parts by mass: apple juice concentrate 12kg; trans-2-hexenol 0.1kg; trans-2-hexenal 0.4kg; trans-2-hexenoic acid 0.02kg; caproic acid 0.2kg; 1% ethyl acetoacetate 2kg; acetic acid 0.03kg; hexanal 0.3kg; acetal 0.05kg; lactic acid 0.2kg; California lemon oil 0.1kg; 0.02kg; leaf alcohol 0.1kg; ethyl butyrate 0.5kg; isoamyl acetate 0.5kg; benzaldehyde 0.3kg;

[0038] The above blending process is a relatively common mixing and stirring process. After weighing each raw material according to the corresponding amount, add it to the blending tank and stir for half an hour, then check and put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com