Regenerative thermal oxidization system and method for operating same

An exhaust gas purification system and thermal storage combustion technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of VOC concentration decrease, change, fuel cost increase, etc., and achieve the effect of mitigating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

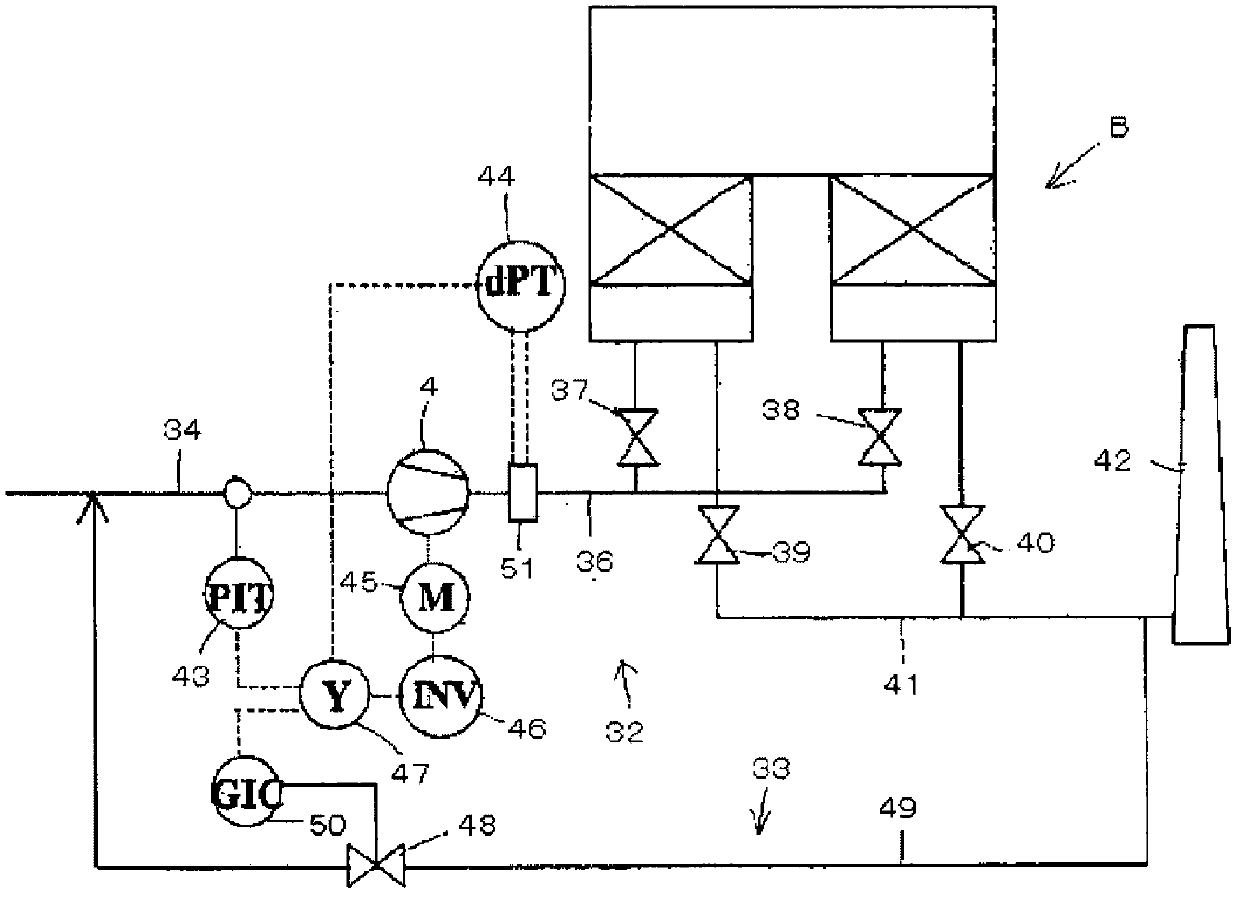

[0022] Embodiments of the present invention will be described below based on the drawings. Here, the same reference numerals are used for the same or similar components, and their repeated descriptions are omitted. The RTO according to one embodiment of the present invention, and the structure of the suction duct device for supplying exhaust gas from the production equipment to the RTO are as follows: figure 1 As shown, in the case of suction from two or more locations, air opening ducts 2, 22 that are always open to the atmosphere are provided on the secondary exhaust side of the exhaust blowers 1, 21 of the production facilities A1, A2. In addition, control gates 5, 25 (gates with adjustable openings) are provided between the air-opening ducts 2, 22 and the blower 4 for RTO and on each exhaust line from each device.

[0023] When the exhaust air volume from the production equipment A1 and A2 reaches the maximum, the overall suction air volume is adjusted by opening the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com