Explosion-proof fuse and method for manufacturing same

A manufacturing method and technology of fuses, which are applied in the manufacture of fuses, emergency protection devices, electrical components, etc., can solve problems such as the inability to determine the normal rated maximum current, injury or dangerous accidents, damage to expensive equipment, etc., to achieve cost reduction and avoidance. Soldering process, the effect of reducing the intermediate process of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

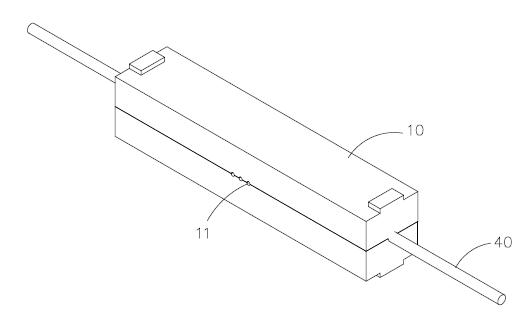

[0025] Such as Figure 1 to Figure 4 As shown, an explosion-proof fuse of the present invention includes a housing 10, a tube body 20, a fuse 30, and pins 40. The housing 10 is a cuboid or cylindrical structure made of plastic material. The side of the housing 10 The wall is provided with openings 11 , and two ends of the housing 10 are provided with clamping holes 12 . The housing 10 includes a lower housing 13 and an upper housing 14, the lower housing 13 and the upper housing 14 are butted and bonded by ultrasonic welding, the lower housing 13 and the upper housing 14 A storage space 15 is formed around it, and the opening 11 and the holding hole 12 communicate with the storage space 15 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com