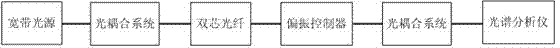

Two-core photonic crystal optical fibre refractive index sensor and sensing system

A technology of photonic crystal fiber and refractive index sensor, which is applied in the direction of cladding fiber, optical waveguide light guide, phase influence characteristic measurement, etc., to achieve the effect of low detection limit, high sensitivity and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

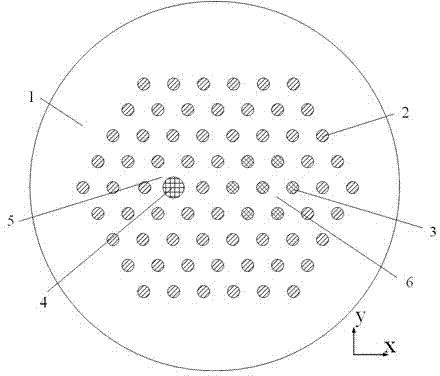

[0038] Such as figure 1 As shown, the matrix material 1 of the dual-core optical fiber is pure quartz, the hole period Λ is 6.487 μm, the diameter of the dielectric rod 4 is 4.925 μm, the diameters of the filling hole 3 and the air hole 2 injected into the sample to be tested are both 3.2435 μm, and the dielectric rod 4 has a diameter of 3.2435 μm. The refractive index of the rod 4 is 0.01 lower than that of the matrix material, and the refractive index of the sample to be tested is 1.33. From figure 1 It can be seen that the fiber core 5 is composed of pure quartz matrix material and the dielectric rod 4; the function of the seven air holes in the microstructure fiber core 6 is to inject the sample to be tested. The relationship between the effective refractive index of the mode in the core 5 and the microstructured core 6 with the normalized frequency is as follows: Figure 4 shown. It can be seen from the figure that the relationship between the two curves is the sam...

Embodiment 2

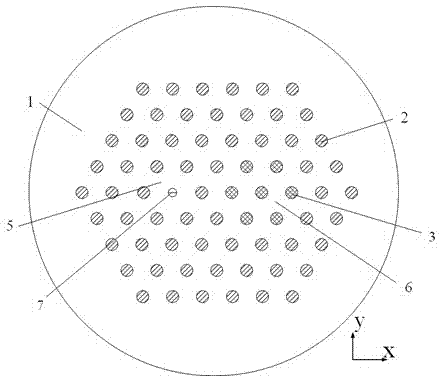

[0040] Its cross-section is as figure 2 As shown, the structural matrix material 1 is quartz, the pore period Λ is 6.487 μm, the diameter of the small air hole 7 is 1.9461 μm, the diameters of the filling hole 3 and the air hole 2 injected into the sample to be tested are both 3.2435 μm, and the sample to be tested The refractive index of 1.33. From figure 2 It can be seen that the fiber core 5 is composed of pure quartz matrix material and small air holes 7; the function of the seven air holes in the microstructure fiber core 6 is to inject the sample to be tested. The relationship between the effective refractive index of the mode in the core 5 and the microstructured core 6 with the normalized frequency is as follows: Figure 8 shown. It can be seen from the figure that the relationship between the two curves is like the second curve discussed above, and they have only one phase matching point in a wide frequency range. When the fiber length is taken as 20.33mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com