Pressing fastener and LED (light-emitting diode) display screen connected by utilizing same

A firmware and display module technology, applied in fixtures, instruments, identification devices, etc., can solve the problems of complex LED display installation, damage to the LED display module, labor and material resources, etc., so as to facilitate daily maintenance and improve installation efficiency. , quick installation and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

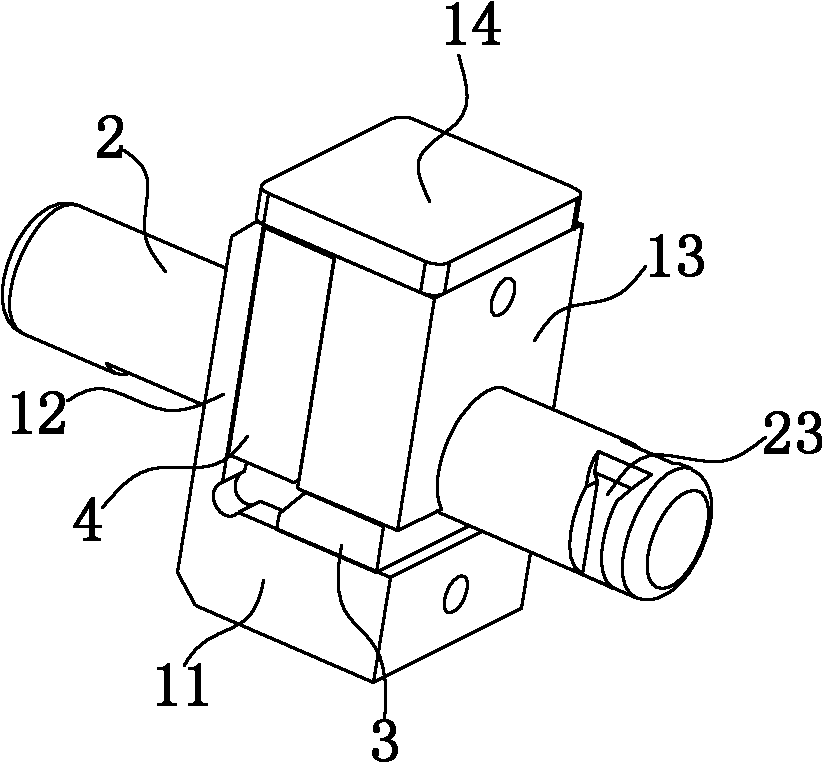

[0050] Such as image 3 , 4 As shown, it is a pressing fastener of the present invention, including a fixed seat, a sliding pin 2, a horizontal slider 3, a longitudinal slider 4, a spring 5 and an anti-off baffle 6, and the horizontal slider 3 can move along the fixed seat. The longitudinal direction (that is, the X direction in the figure) slides relative to the fixed seat, and the longitudinal slider 4 can slide relative to the fixed seat along the height direction of the fixed seat (that is, the Y direction in the figure), and the sliding pin 2 slides along the fixed seat. The length direction extends and passes through the fixed seat. The fixed base includes a base plate 11, a side baffle 12, a block 13 and a top plate 14, wherein the side baffle 12 is connected to the upper surface of the rear end of the base plate 11, and the top plate 14 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com