Heat dissipation structure for wind generating set

A technology for wind turbines and heat dissipation structures, applied in wind turbine components, wind turbine combinations, wind turbines, etc., can solve the problems of inability to provide cooling by hot air, radiator failure, seawater corrosion, etc., and achieve stable and reliable cold source. , The cooling effect is stable and the production cost is saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

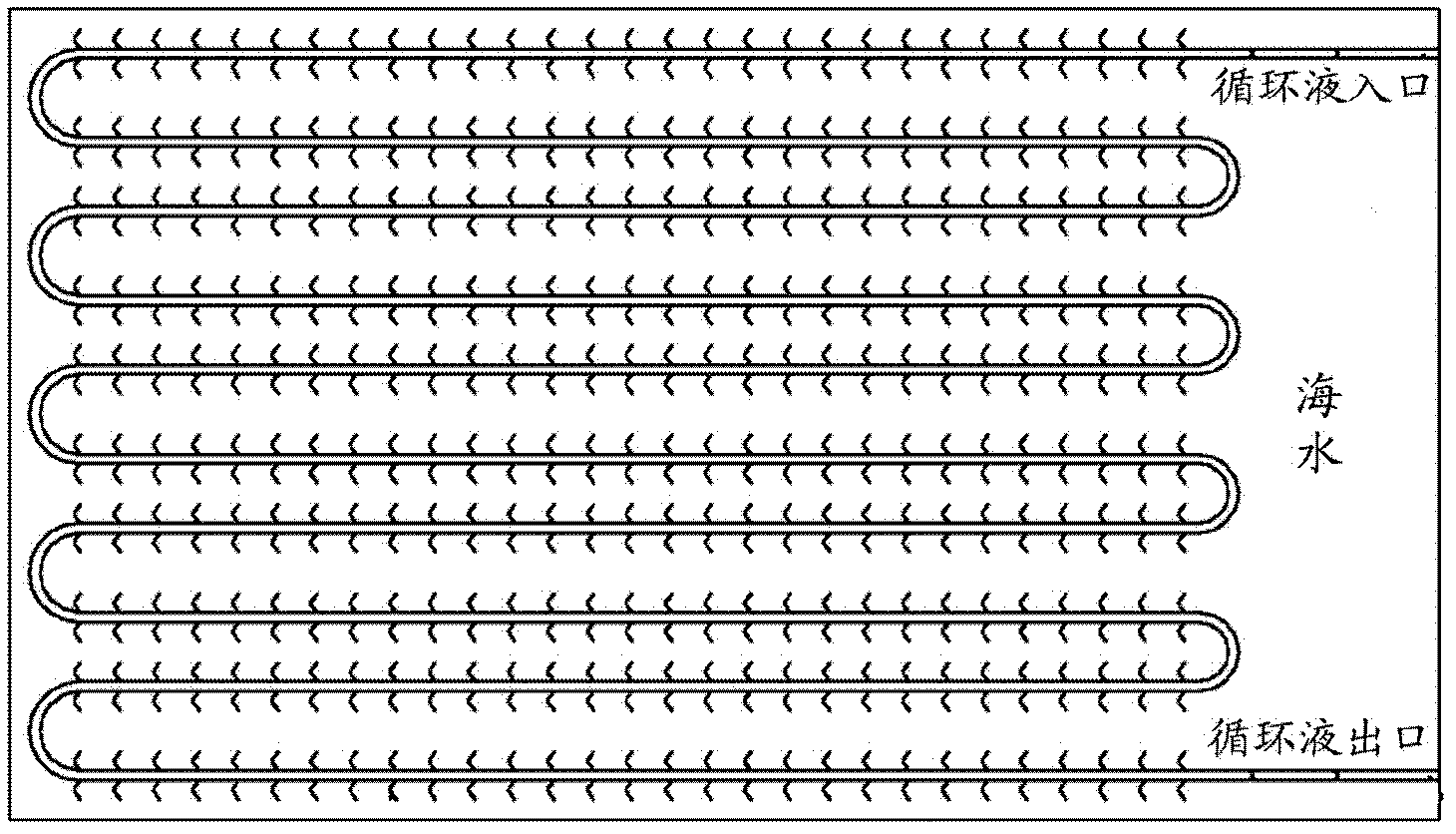

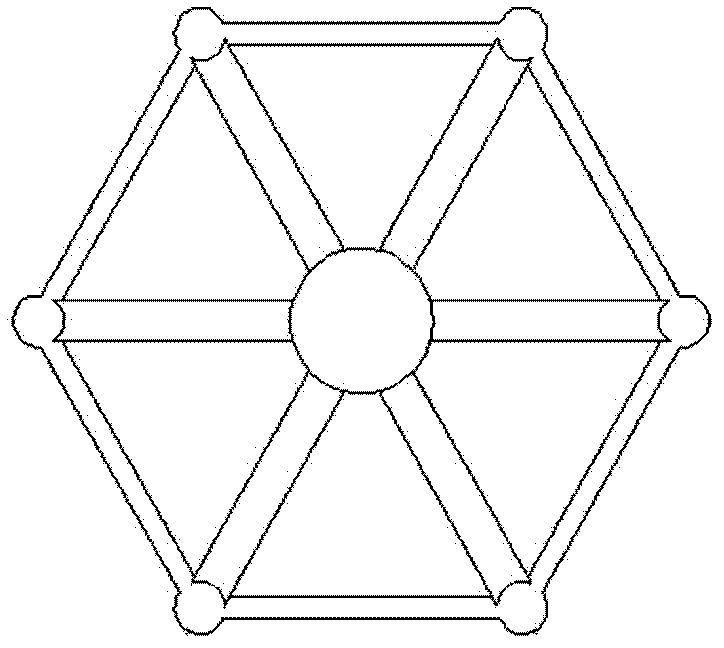

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In each of the following embodiments, a wind power generating set with six piles is taken as an example for illustration, but the present invention is not limited thereto, and can be applied to various types of seawater wind generating sets.

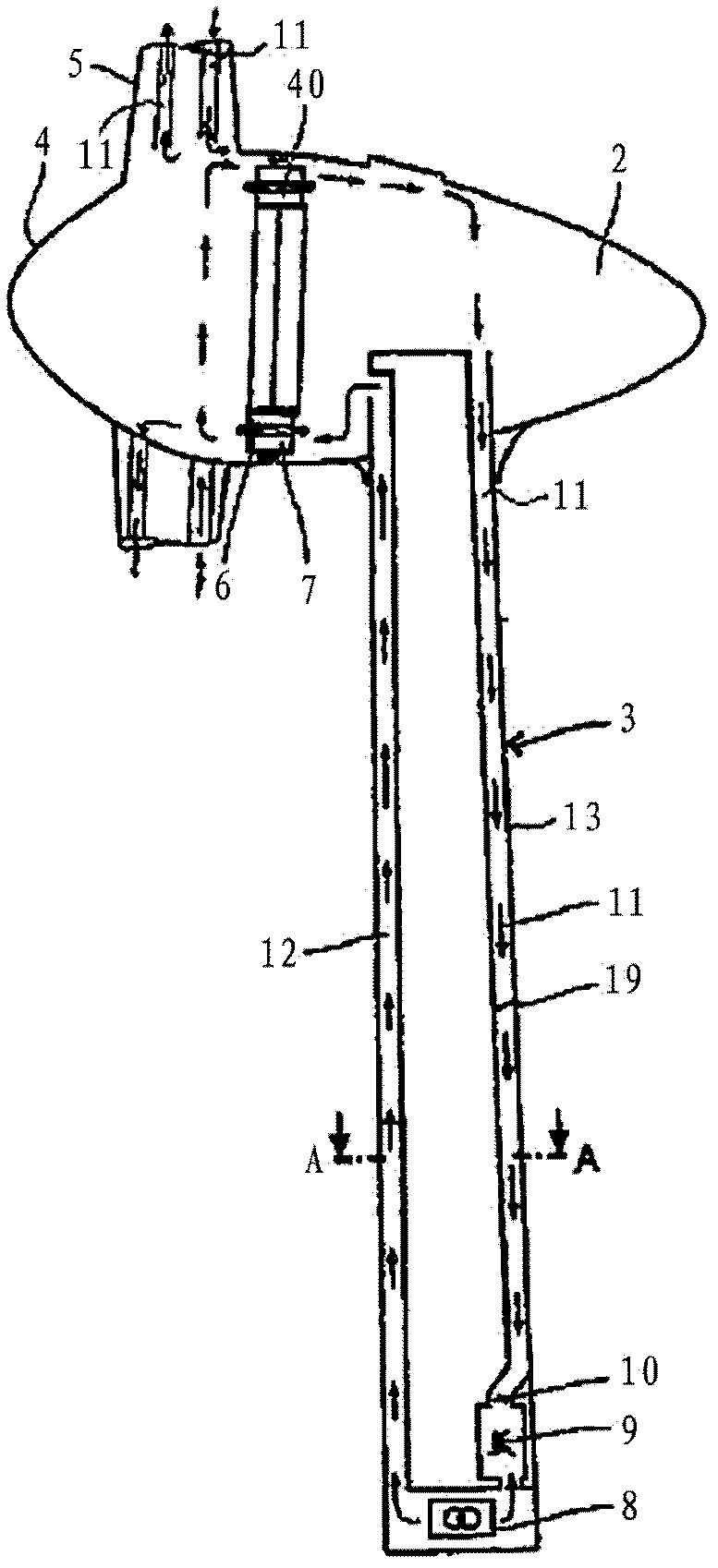

[0028] image 3 is a top view of a wind turbine according to the present invention, Figure 4 for image 3 Partial cutaway view of a wind turbine.

[0029] The wind power generating set according to the present invention generally includes a tower 1 , a support frame 2 , a pile body 3 and a beam 4 . Various electrical equipment (for example, generators, converters, transformers, etc.) are arranged on the inner upper side of the tower 1 . One end of the support frame 2 is connected to the tower tube 1 , and the other end is connected to the pile body 3 , and each support frame 2 forms an inclined state to supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com