Concrete synergist and preparation method for same

A concrete synergist and concrete technology, applied in the field of concrete materials, can solve the problems of insufficient hydration reaction of cement cementitious materials, inability to effectively exert the strength of cement, and it is difficult for concrete to function again, and achieve good dispersion and reduce concrete cracks. , the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of above-mentioned concrete synergist comprises the following steps:

[0027] (1) take each component by weighing;

[0028] (2) Add each component to the reaction kettle in turn;

[0029] (3) The reaction kettle is kept at 70-75° C., and the finished product is obtained after stirring for 3 hours.

Embodiment 1

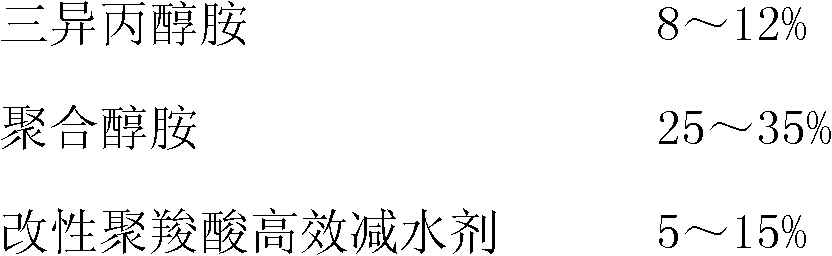

[0031]

[0032] Add triisopropanolamine, polymerized alcoholamine, modified polycarboxylate high-efficiency water reducer, pulp black liquor extract and water into the reactor in sequence, keep the temperature in the reactor at 70°C, and stir for 3 hours to prepare The finished product is named A.

[0033] In the concrete preparation process, cement is first mixed with auxiliary materials, and then 0.6 kg of A is added to 100 kg of the mixed material, and water is added at the same time, and the concrete material is obtained after stirring evenly.

Embodiment 2

[0035]

[0036] Add triisopropanolamine, polyalcoholamine, modified polycarboxylate high-efficiency water reducer, pulp black liquor extract and water into the reactor in sequence, keep the temperature in the reactor at 75°C, and stir for 3 hours to prepare The finished product is named B.

[0037] In the concrete preparation process, the cement is first mixed with auxiliary materials, and then 1 kg of B is added to 100 kg of the mixed material, and water is added at the same time, and the concrete material is obtained after stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com