Solid tire structure

A technology of solid tires and tires, which is applied to tire parts, non-pneumatic tires, transportation and packaging, etc. It can solve the problems of reducing the inner circumference of the fixed steel wire B', increasing the cost of materials, and large binding force, so as to suppress the failure of ROLLING , saving steel wire cloth, avoiding the effect of relative peristalsis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

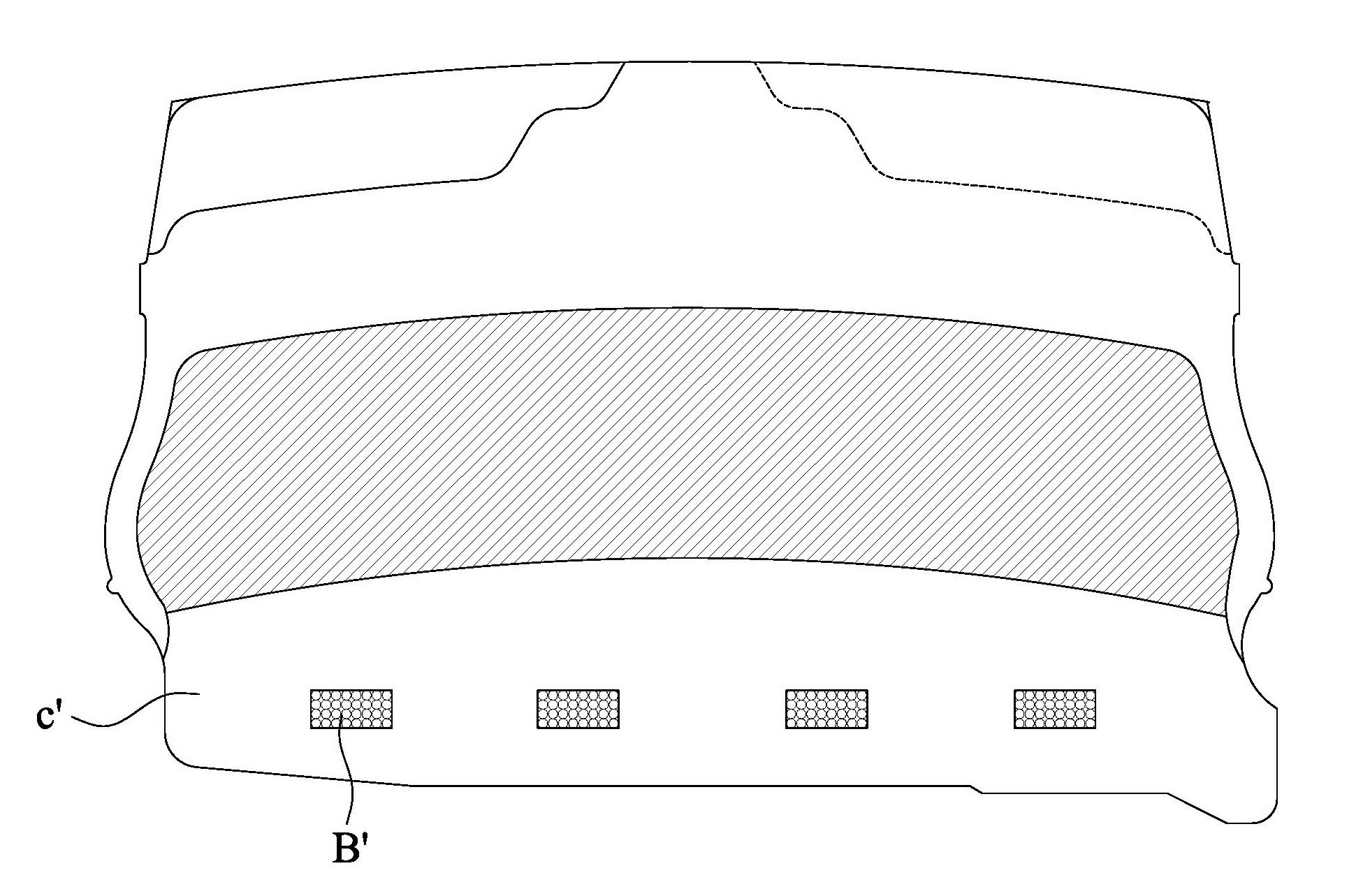

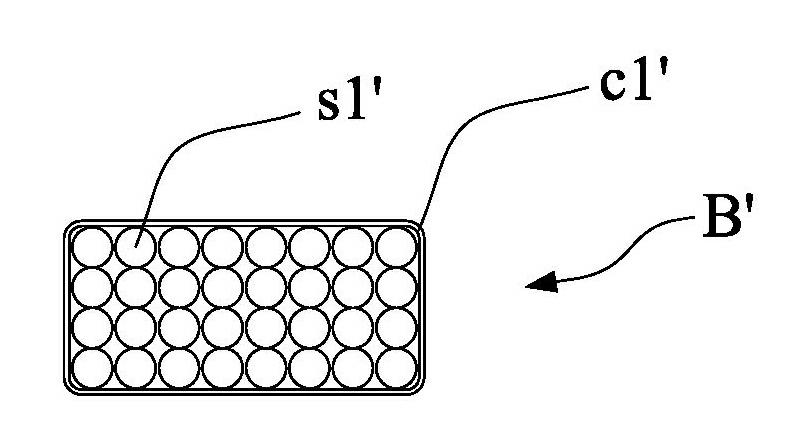

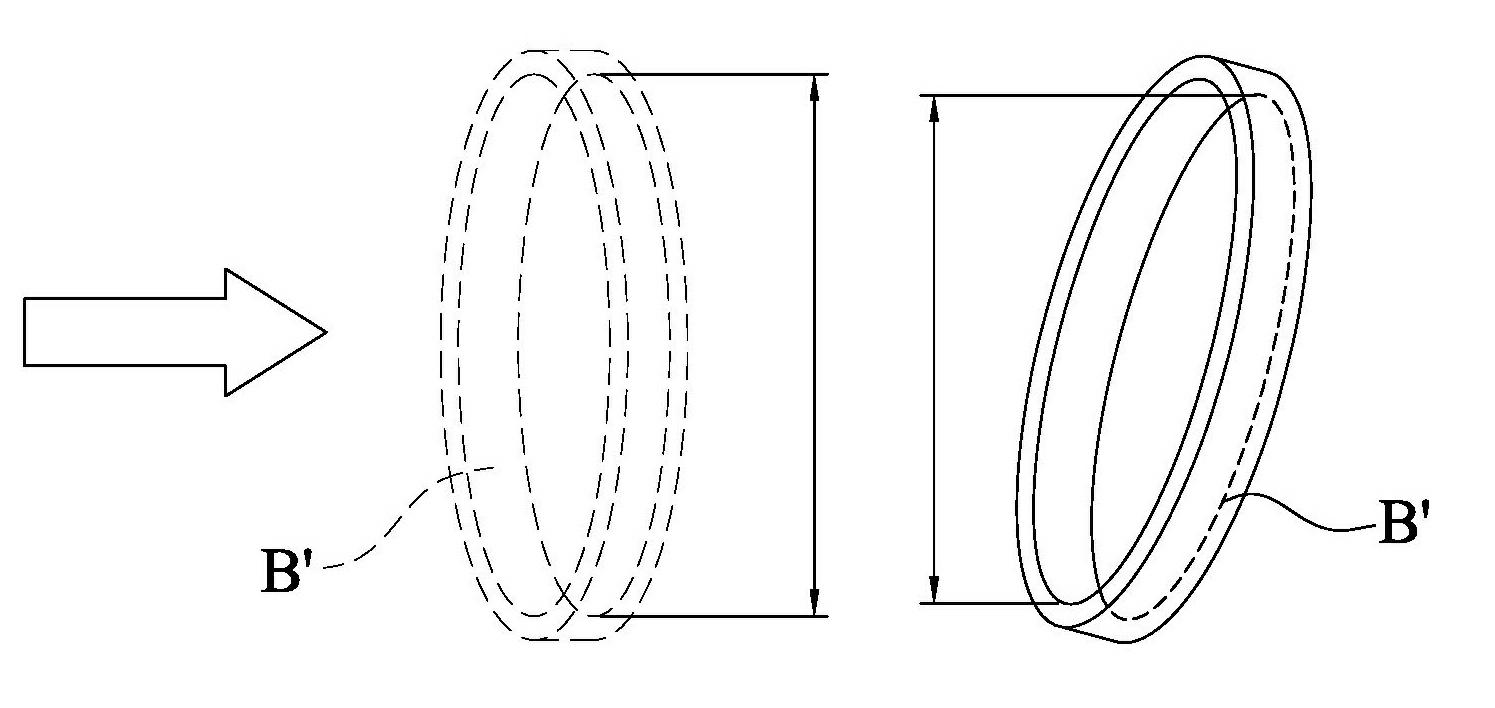

[0050] Such as Figure 4 to Figure 8 As shown, the present invention discloses a solid tire structure, which is composed of two or more than two kinds of rubber materials. Glue fixed steel wire B.

[0051] Such as Figure 4 As shown, the tire 1 of this embodiment is composed of three kinds of rubber materials, namely the outer layer rubber a, the middle layer rubber b, and the inner layer rubber c; the outer layer rubber a is designed to be wear-resistant, aging-resistant, and cut-resistant. The side extension part 10 needs to cover the middle layer rubber b and the inner layer rubber c, and form the pattern blocks 11 and grooves 12 of the tire 1 on the upper surface of the outer layer rubber a. The upper contact point of rim 2 is below 13, mainly because the aging performance and cutting resistance of the middle rubber b is inferior to that of the outer rubber a; while the middle rubber b is designed as a low heat-generating rubber material, and the rubber material is soft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com