A kind of flattening processing method of moso bamboo

A processing method and bamboo technology, applied in the direction of sugarcane machining, mechanical equipment, etc., can solve the problems of low yield and reduce the market price of bamboo products, so as to solve the problem of low yield, improve technological content and product added value, The effect of avoiding pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of flattening processing method of moso bamboo material comprises the steps:

[0022] Step 1: harvesting fresh moso bamboo, removing the sundries on the bamboo stem, and cutting the moso bamboo into bamboo segments;

[0023] Step 2: Detect the diameter of the small head of the bamboo section and stack it in classification, and break the bamboo section into bamboo pieces;

[0024] Step 3: In order to obtain a satisfactory flattening effect of the bamboo, all the inner and outer nodes of the bamboo are removed to form a smooth state with the inner and outer walls of the bamboo slice;

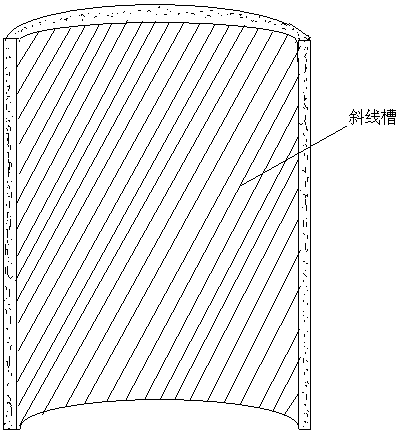

[0025] Step 4: Carve multiple chute lines with a depth of about 1 mm on the inner surface of the bamboo slices with a manual grooving machine;

[0026] Step 5: Put the bamboo slices processed with inclined grooves into the clear water pool for soaking, add weights to make them completely soaked in the clear water, and regularly replace the clear water in the clear water pool to prev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap