Automatic assembly line for sprinklers

An automatic assembly and assembly line technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as unsatisfactory assembly quality, low assembly efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

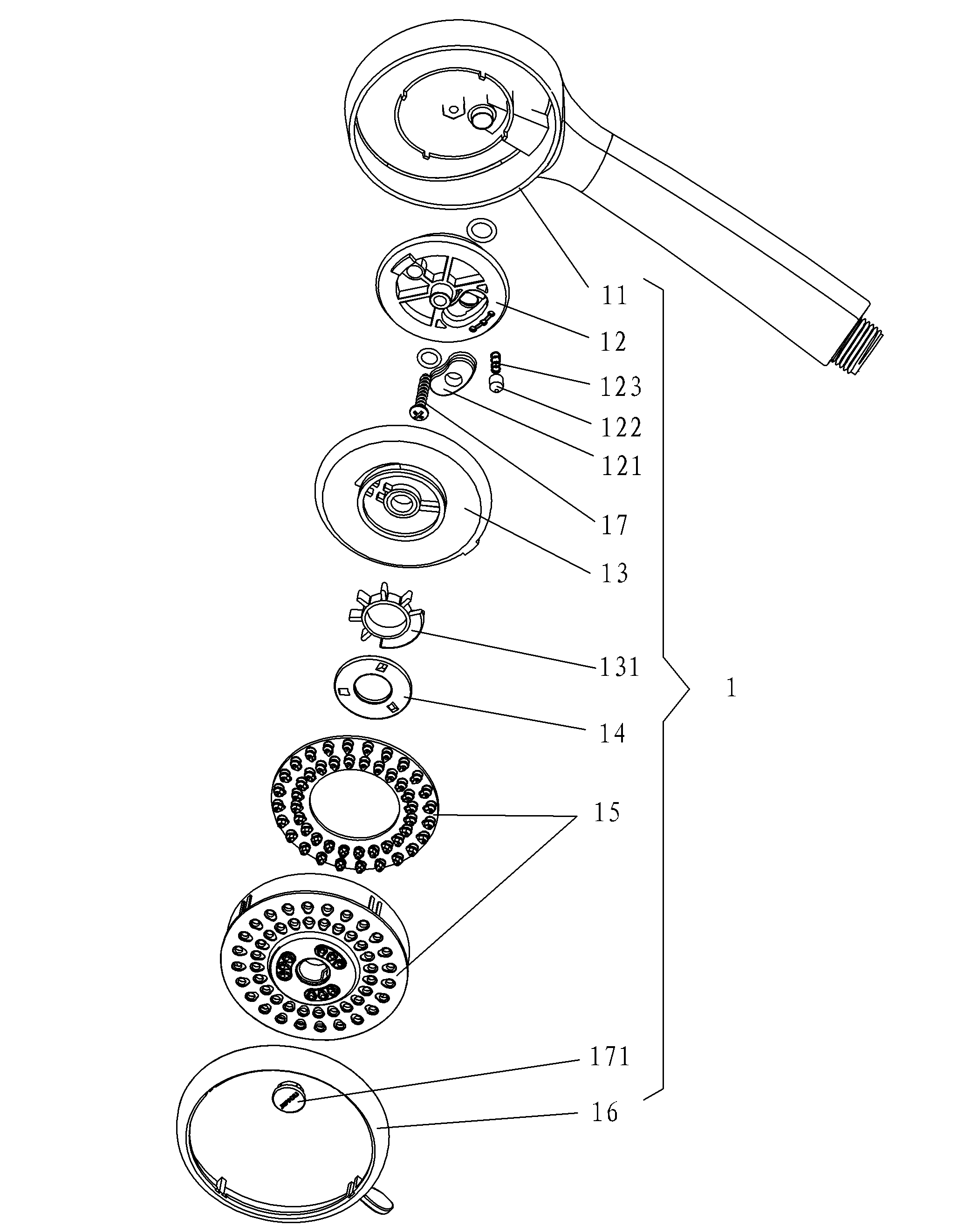

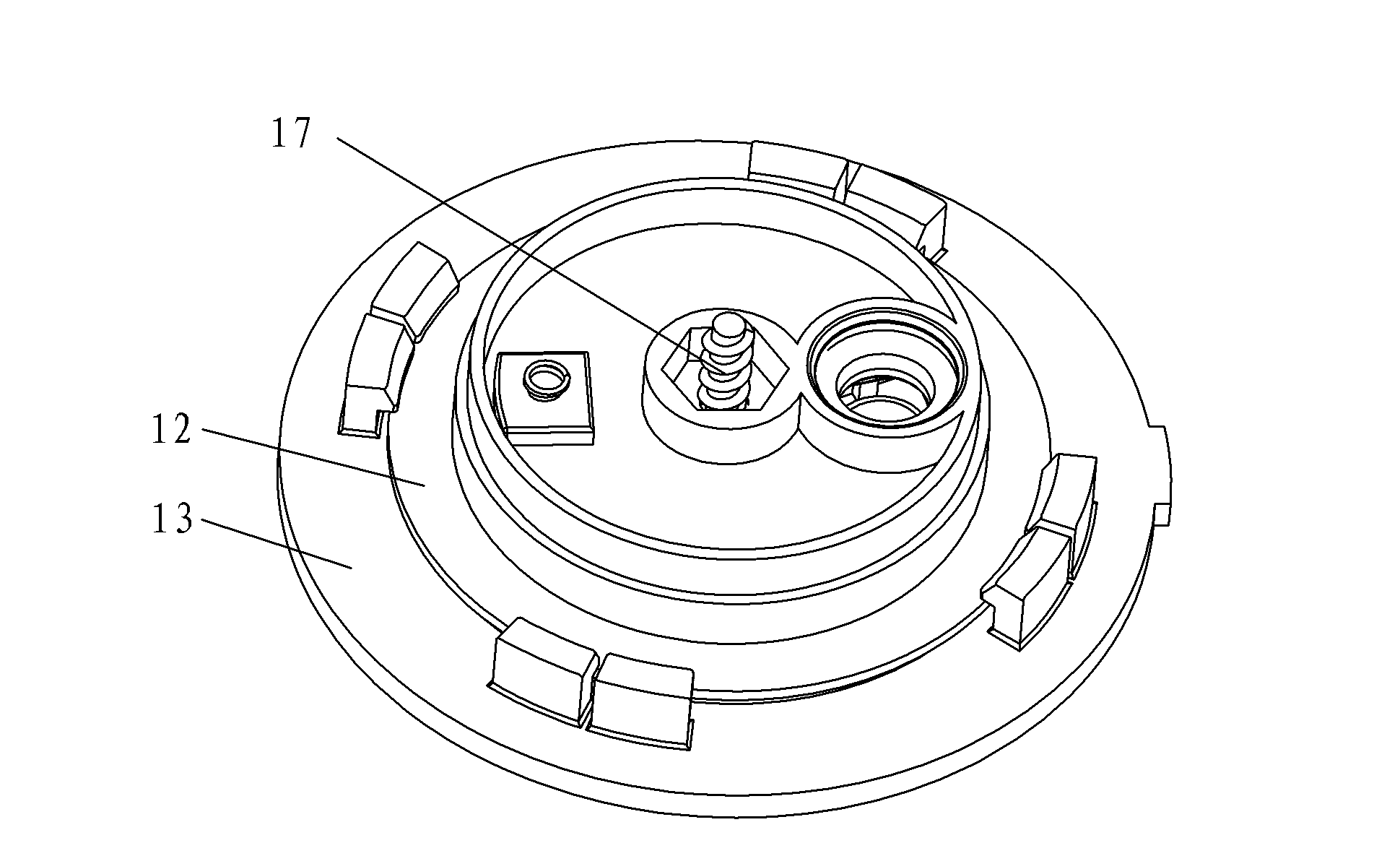

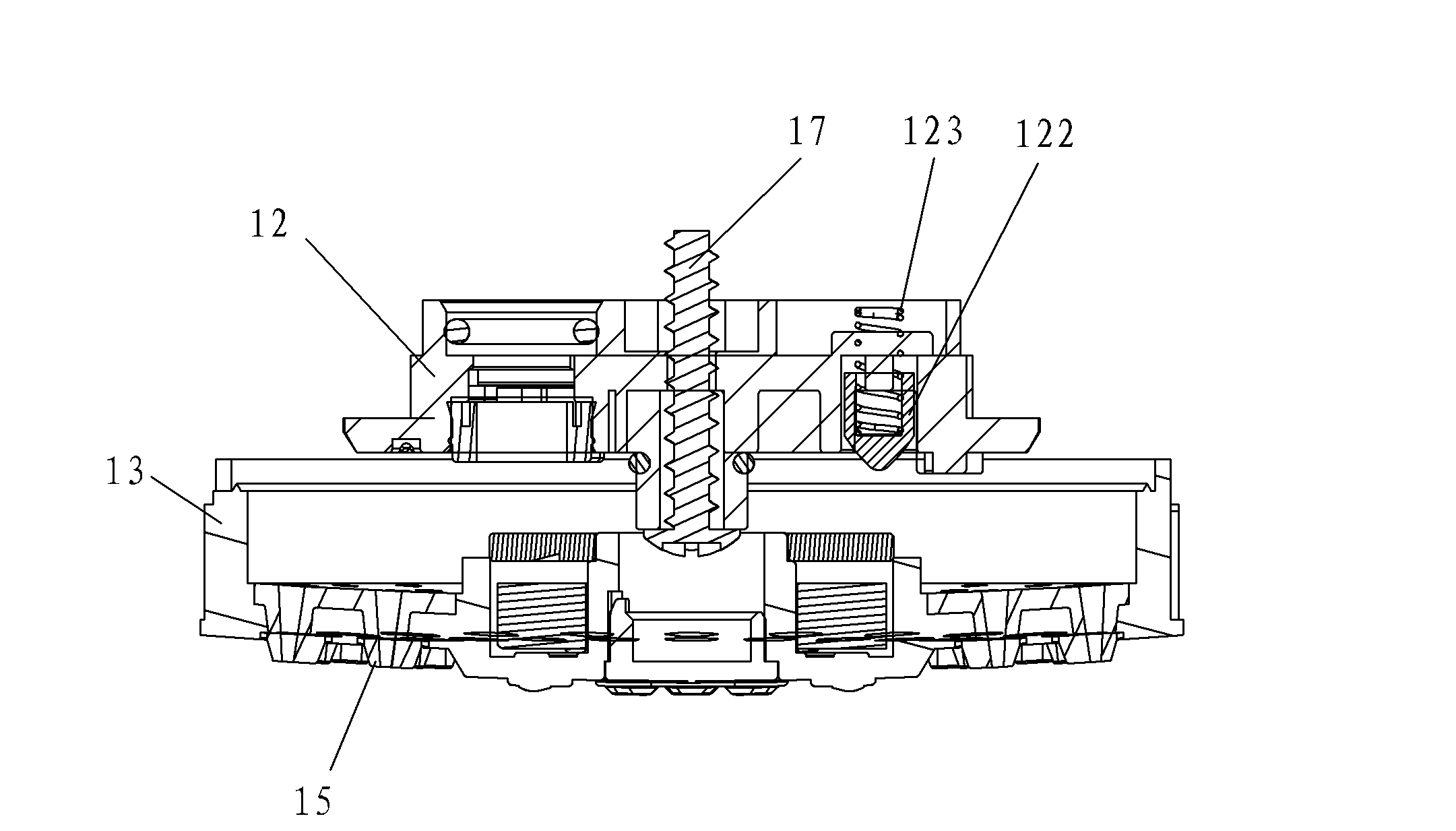

[0052] Such as Figures 1 to 4 As shown, the shower 1 assembled in the shower automatic assembly line of the present invention mainly includes components such as a body 11, a fixing plate 12, a water diversion plate 13, an inclined water body 14, and a panel group 15 arranged in sequence; It is fixed on the body 11, the bolt cover 171 is covered on the head of the bolt 17, and the retaining ring 16 is sleeved on the panel group 15, all of which play a certain decorative role.

[0053] Such as Figures 5 to 10 As shown, the shower automatic assembly line of the present invention mainly includes a first conveyor belt 2, a first assembly line 3, a second conveyor belt 4, a third conveyor belt 5a, a vibrating discharge table 5b, a second assembly line 6 and a control cabinet 7. Wherein, each output end of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com