Grid shearing fixation device for lead-acid storage battery

A technology for fixing devices and grids, which is applied in the direction of shearing devices, attachments of shearing machines, metal processing equipment, etc., and can solve the problems that restrict the popularization and application of new cutting knives and cannot work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

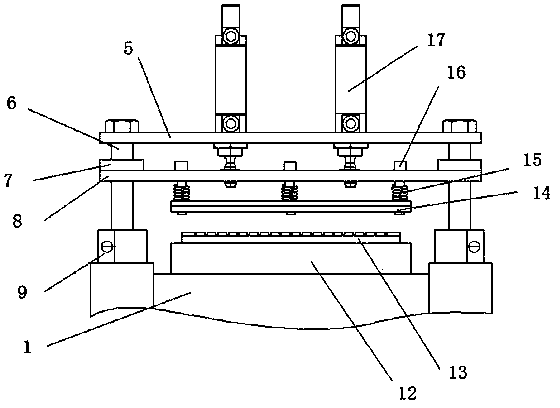

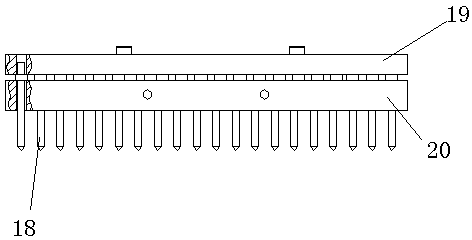

[0023] Such as figure 1 As shown, the grid shearing and fixing device A in the present invention is arranged in front of the shearing device 1, and is positioned on the movement path of the grid, as figure 2 As shown, it includes a fixed seat and a pressing plate fixing mechanism and a tendon carding mechanism arranged on the fixed seat.

[0024] Such as Figure 2-5 As shown, the fixed seat includes a base 9, a fixed seat plate 5 and a carding mechanism installation plate 22, and the base 9 and the fixed seat plate 5 are connected by two guide rods 6 in the first guide mechanism. The pressing plate fixing mechanism comprises a lower fixing plate 13, an upper fixing plate 14, a pressing plate driving mechanism and a first guiding mechanism. The first guide mechanism includes two guide rods 6 and a sliding seat which is arranged on the guide rods 6 and can reciprocate along the guide rods 6 . The lower ends of two guide rods 6 are fixed on the frame 1 of the transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com