Liver aid troche and preparation method thereof

A technology for Yiganling tablets and tablets, which are applied in the directions of pill delivery, pharmaceutical formulations, and medical preparations with inactive ingredients, etc., can solve the problems of uneven surface, unfavorable large-scale production, and low yield, and achieve a one-sided solution. The effect of unevenness, reducing the generation of waste and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Example 1 prepares Yiganling tablet:

[0037]

[0038] (1) Silymarin sieved with 60 mesh, calcium hydrogen phosphate with 60 mesh, starch with 100 mesh, calcium sulfate with 18 mesh, sucrose crushed with 80 mesh, carboxymethyl starch sodium with 100 mesh, magnesium stearate with 100 mesh Sieve for use;

[0039] (2) Preparation of 15% starch slurry: put 2.0 g of starch into a stainless steel slurry mixing tank, add 11.3 g of purified water, stir until it reaches a concentration of 15%, and set aside.

[0040] (3) Put the standby silymarin, calcium hydrogen phosphate, calcium sulfate, sucrose and starch in step (1) into a high-speed wet granulator in turn, after stirring for 5 minutes, add the starch slurry prepared in step (2), and stir for 3 minutes to obtain wet particles;

[0041] (4) The wet granules prepared in step (3) are granulated with a 18-mesh nylon net in a swing machine, and after drying in an oven at 60 to 65° C. for 2.5 hours, granulate with a 18-mesh...

example 2

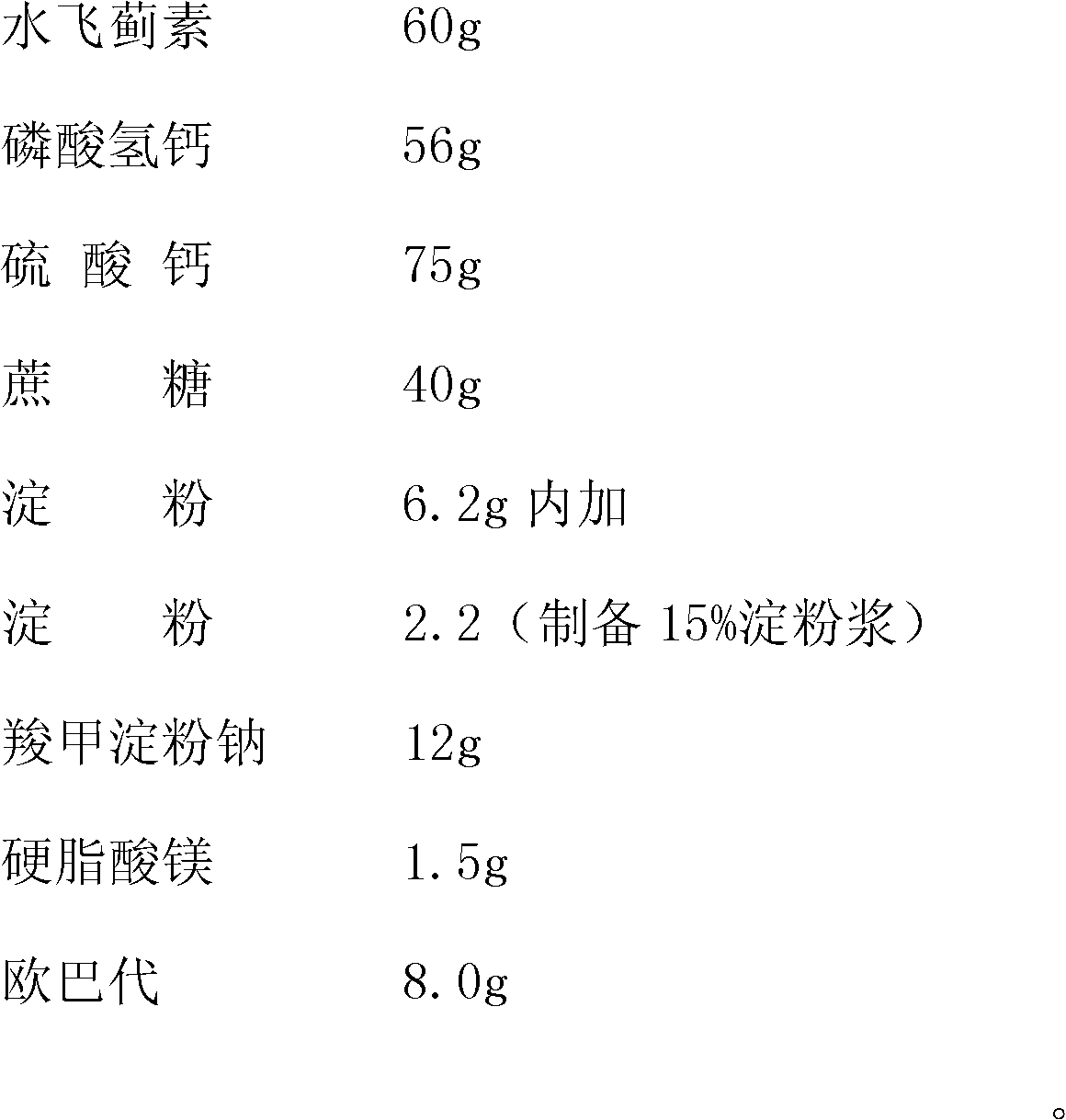

[0045] Example 2 prepares Yiganling tablet:

[0046]

[0047] (1) Silymarin sieved with 60 mesh, calcium hydrogen phosphate with 60 mesh, starch with 100 mesh, calcium sulfate with 18 mesh, sucrose crushed with 80 mesh, carboxymethyl starch sodium with 100 mesh, magnesium stearate with 100 mesh Sieve for use;

[0048] (2) Preparation of 15% starch slurry: put 2.2 g of starch into a stainless steel slurry mixing tank, add 12.5 g of purified water, stir until it reaches a concentration of 15%, and set aside.

[0049] (3) Put the standby silymarin, calcium hydrogen phosphate, calcium sulfate, sucrose and starch in step (1) into a high-speed wet granulator in turn, after stirring for 5 minutes, add the starch slurry prepared in step (2), and stir for 3 minutes to obtain wet particles;

[0050] (4) The wet granules prepared in step (3) are granulated with a 18-mesh nylon mesh of a swing machine, and after drying in an oven at 65 to 70° C. for 2 hours, granulated with a 18-mesh...

example 3

[0054] Example 3 prepares Yiganling tablet:

[0055]

[0056] (1) Silymarin sieved with 60 mesh, calcium hydrogen phosphate with 60 mesh, starch with 100 mesh, calcium sulfate with 18 mesh, sucrose crushed with 80 mesh, carboxymethyl starch sodium with 100 mesh, magnesium stearate with 100 mesh Sieve for use;

[0057] (2) Preparation of 15% starch slurry: put 2.5 g of starch into a stainless steel slurry mixing tank, add 14.2 g of purified water, stir until it reaches a concentration of 15%, and set aside.

[0058] (3) Put the standby silymarin, calcium hydrogen phosphate, calcium sulfate, sucrose and starch in step (1) into a high-speed wet granulator in turn, after stirring for 5 minutes, add the starch slurry prepared in step (2), and stir for 3 minutes to obtain wet particles;

[0059] (4) The wet granules prepared in step (3) are granulated with a 18-mesh nylon mesh of a swing machine, and after drying in an oven at 70 to 75° C. for 1.5 hours, granulated with a 18-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com