Minimum triggering angle running test method for high-voltage direct current power transmission converter valve

A high-voltage direct current transmission and operation test technology, applied in the field of power electronics, can solve problems such as poor compatibility, and achieve good generality and good method versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

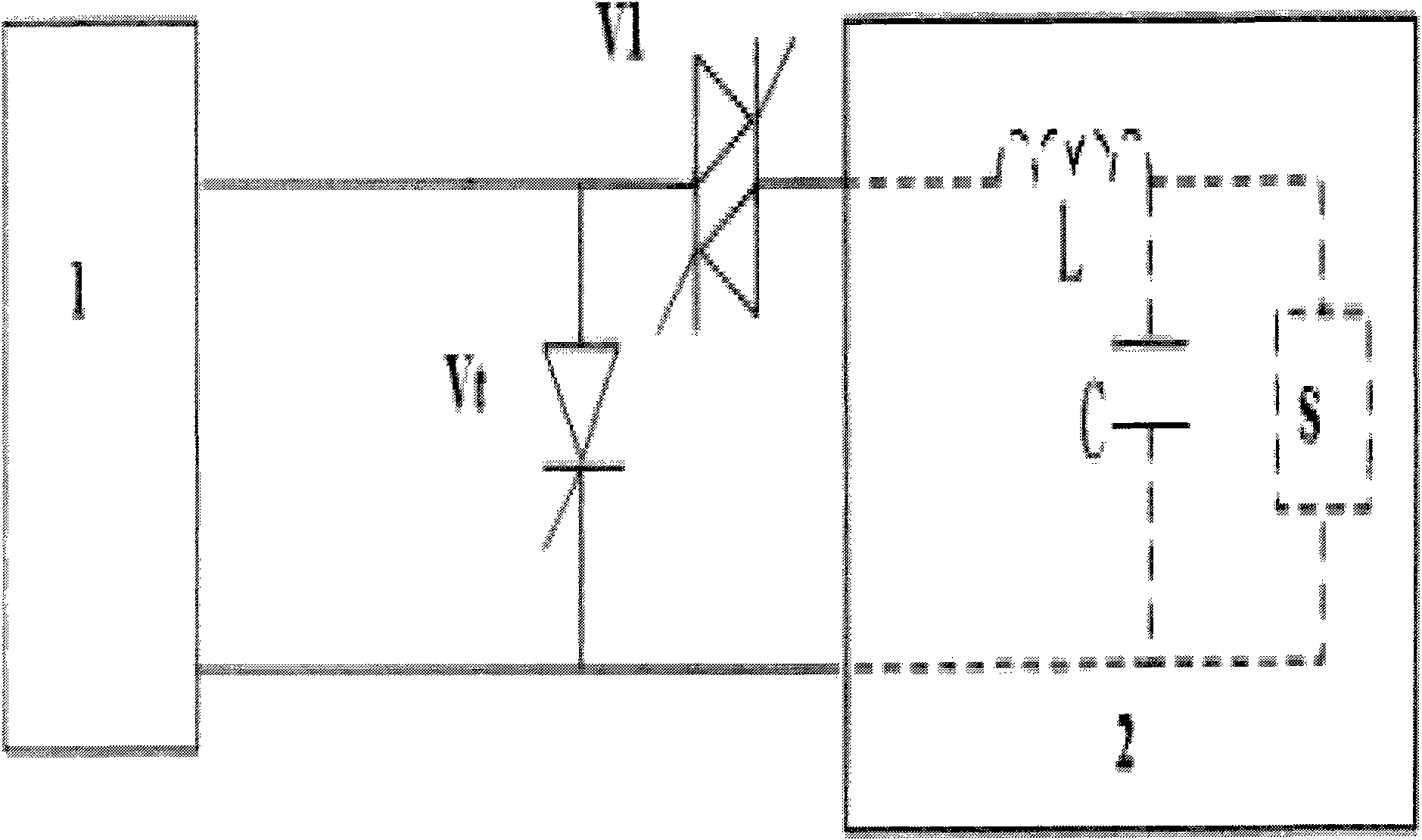

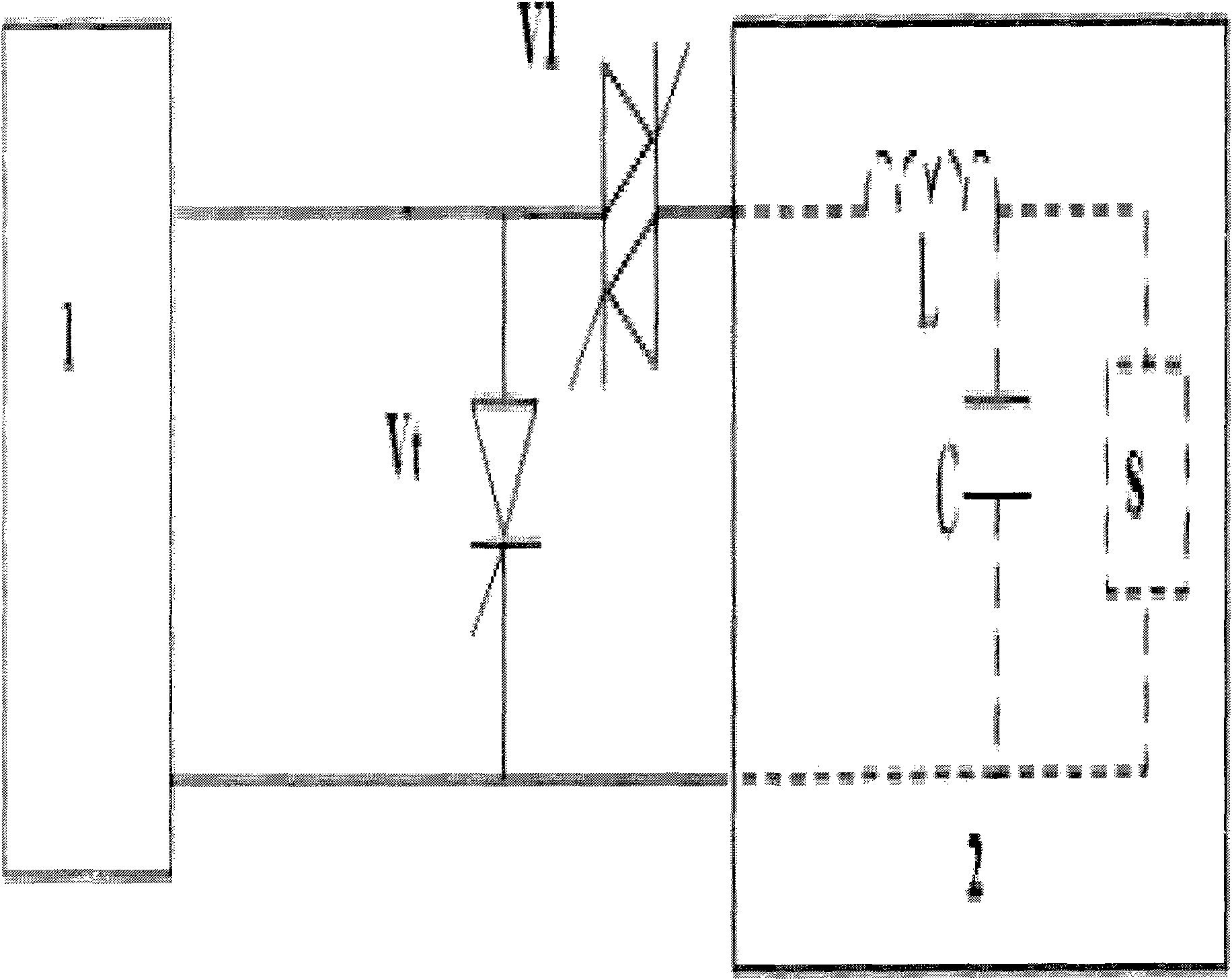

[0023] figure 1 It is a schematic diagram of the minimum trigger angle operation test device for HVDC converter valves. The device includes low-voltage high-current DC power source 1, high-voltage small current source 2, auxiliary valve V1 and test valve Vt, among which low-voltage high-current DC source 1, test Sample valve Vt and high-voltage small current source 2 are connected in parallel in turn; one end of auxiliary valve V1 is connected to low-voltage high-current DC source 1, test valve Vt and high-voltage small current source 2, and the other end of auxiliary valve V1 is connected to the resonance in high-voltage small current source 2. Inductor L; high voltage and small current source 2 includes charging power source S, resonant capacitor C and resonant inductor L, charging power source S and resonant capacitor C are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com