Unfurled metal sealing ball valve

A metal-sealed, spread-out technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of long guide groove travel, affecting valve quality, and easy mutual damage, etc., and achieves low manufacturing costs. Easy to process and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

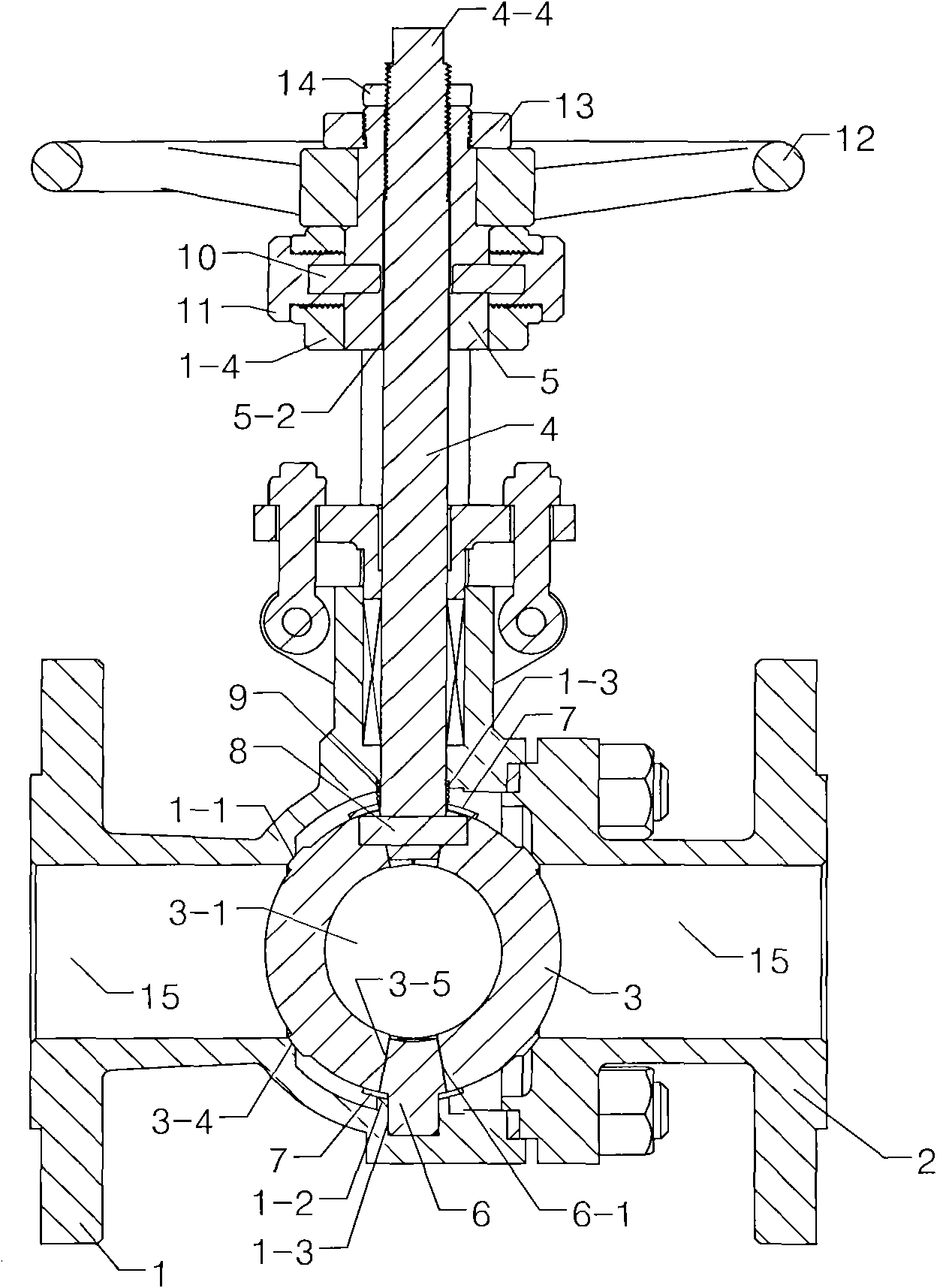

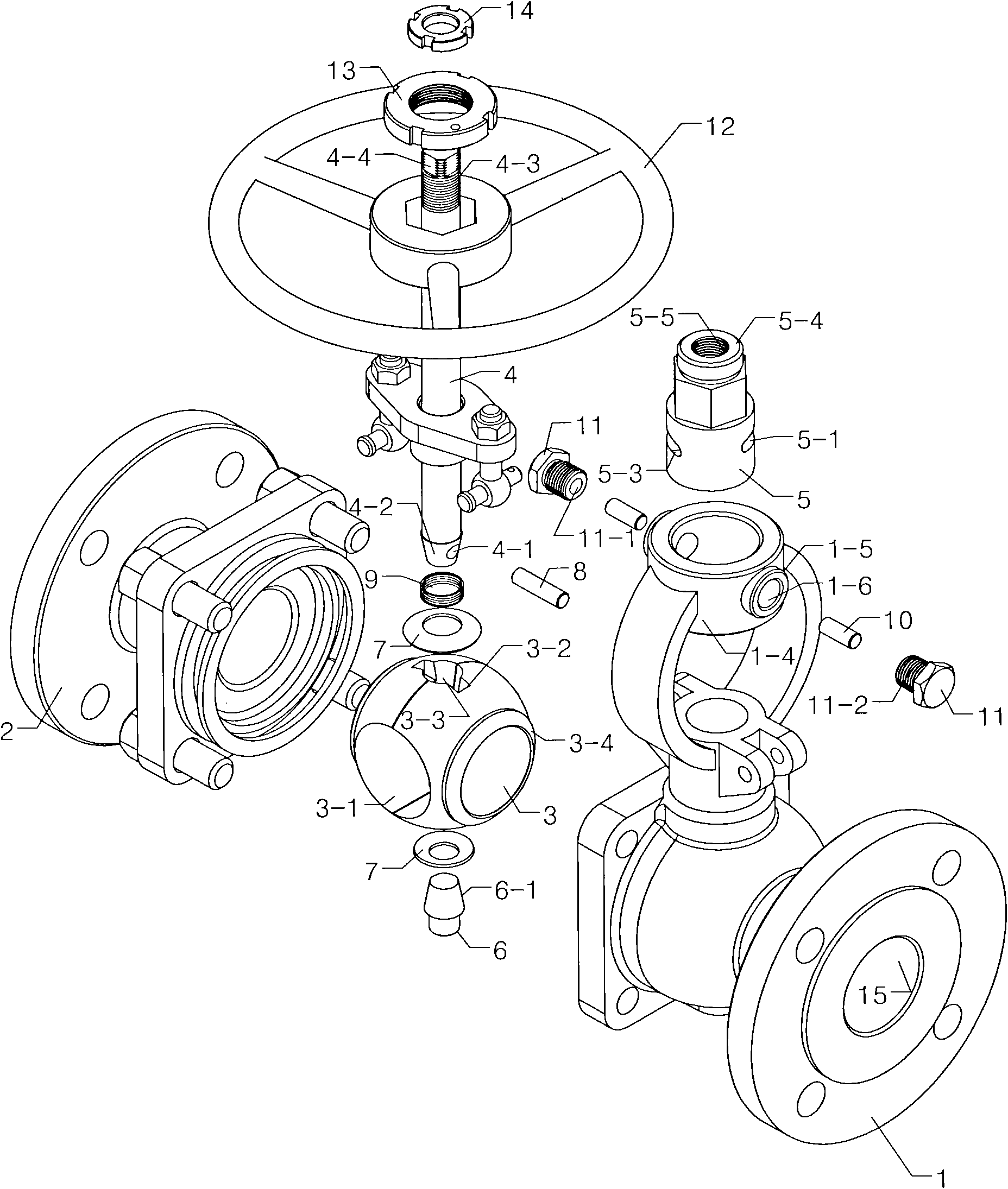

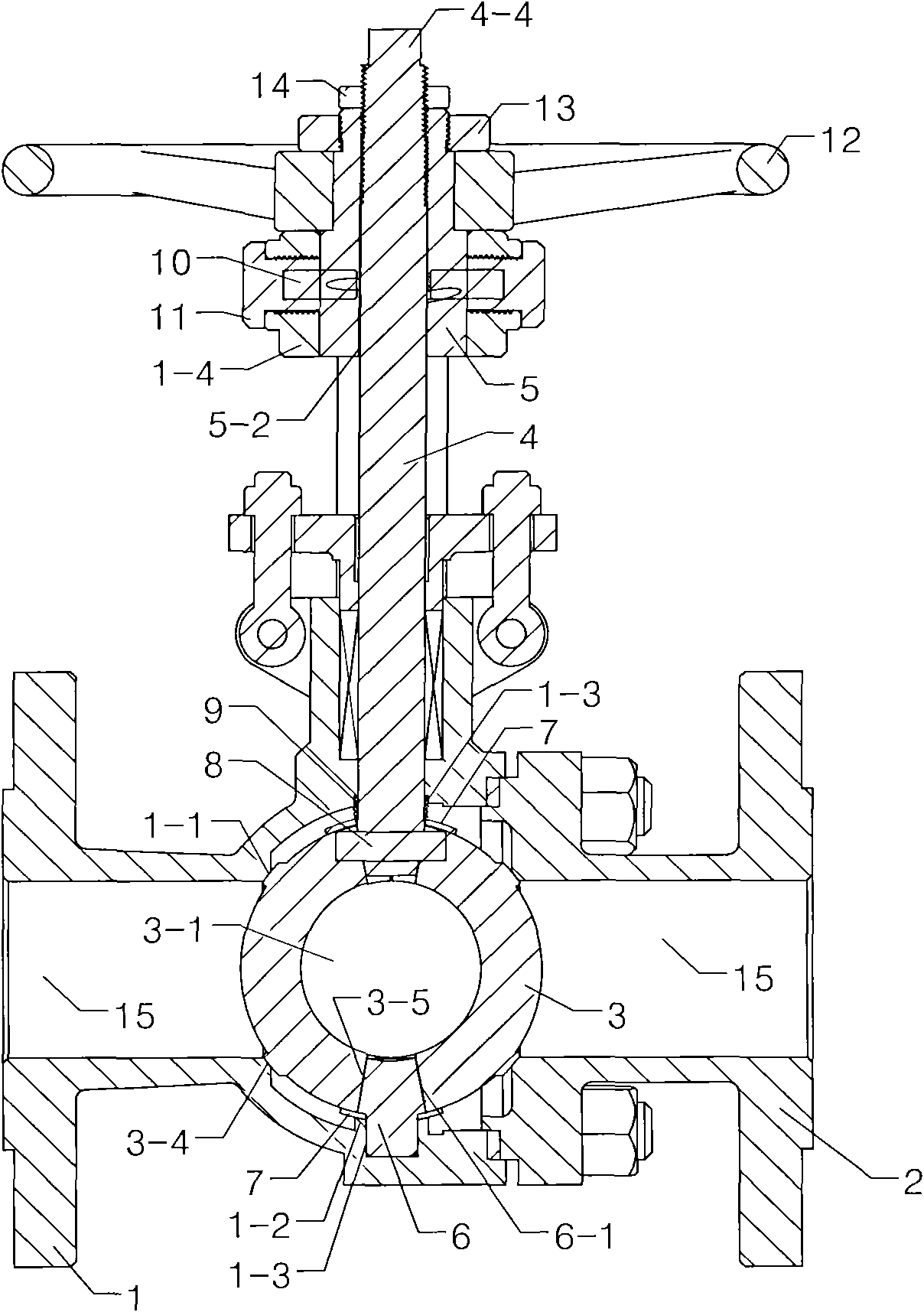

[0038] According to the embodiment of the present invention, the ball valve mainly includes a valve body (1) and a connecting body (2), a channel (15) for transmitting liquid medium is provided in the inner cavity of the valve, and a channel (15) is provided between the opening and closing positions of the valve in the channel. A sphere (3) that selectively rotates to control liquid flow. The sphere (3) is a two-piece structure that is symmetrical to each other. The sealing surface of the raised annular flange (1-1) (commonly called the valve seat) so that the seal (3-4) of the mating ball (3) is pressed against it.

[0039]In order to ensure that the sphere (3) has a certain positional relationship while moving in the valve body (1), a round table (1-2) is set at the lower end of the valve body (1), and the vertical center of the sphere (3) has a container The cone (4-2) at the end of the valve stem (4) and the cone plug (6) match the same holes (3-3) and (3-5), and the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com