Deposited film formation device and deposited film formation method

A technology for depositing films and electrodes, applied in gaseous chemical plating, coatings, electrical components, etc., can solve problems such as uneven temperature distribution, and achieve the effect of suppressing the temperature rise of the second electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

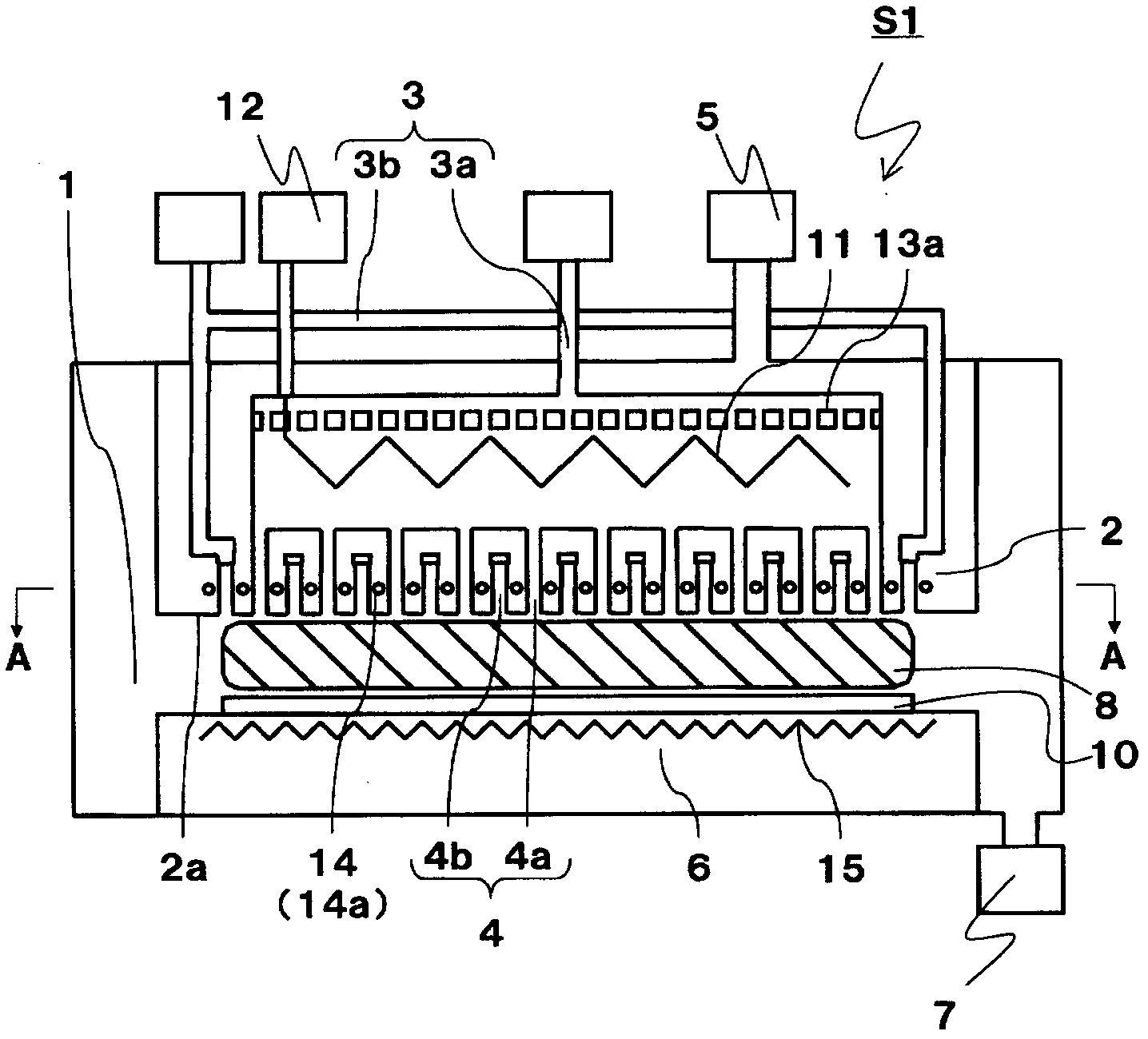

no. 1 example

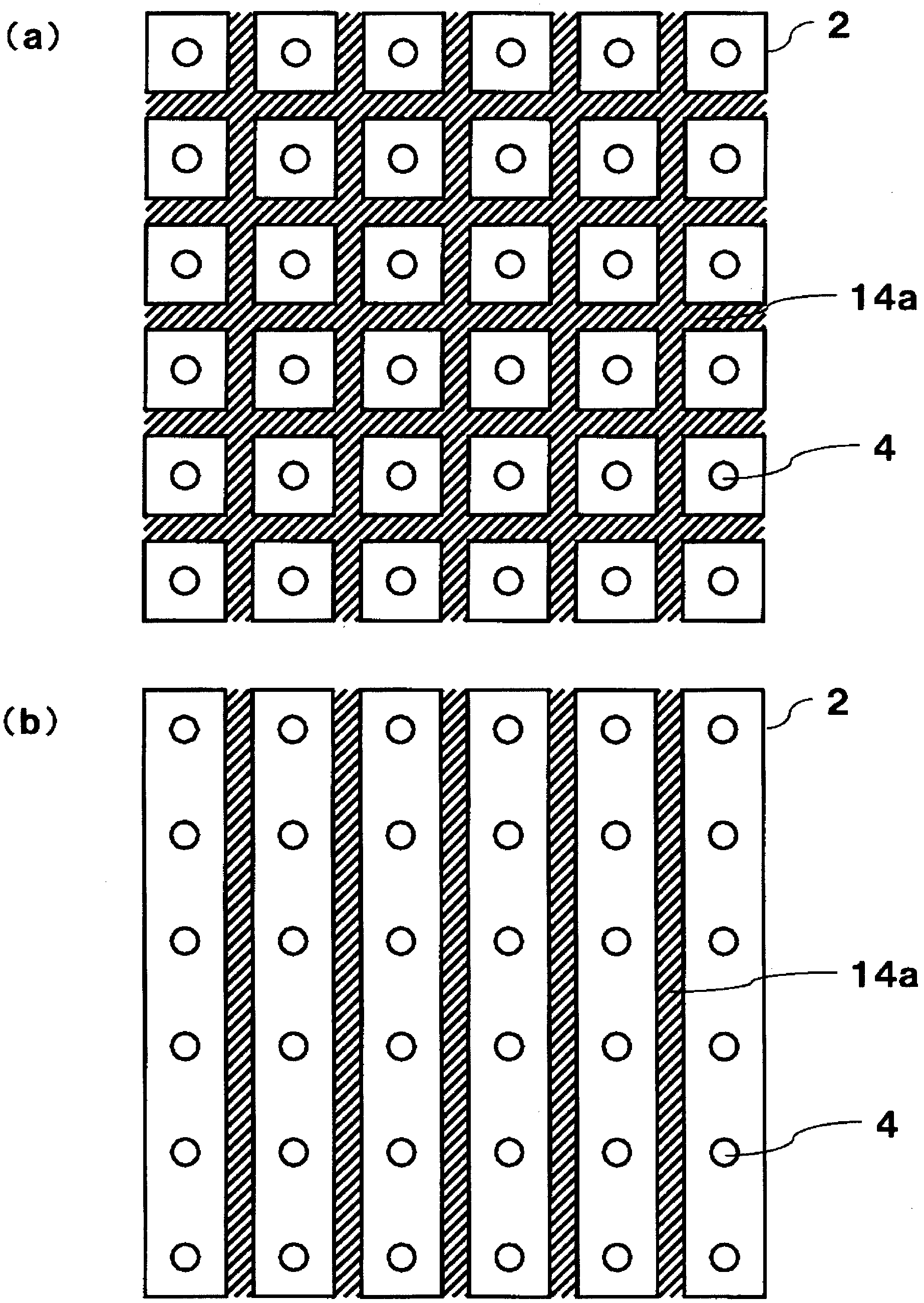

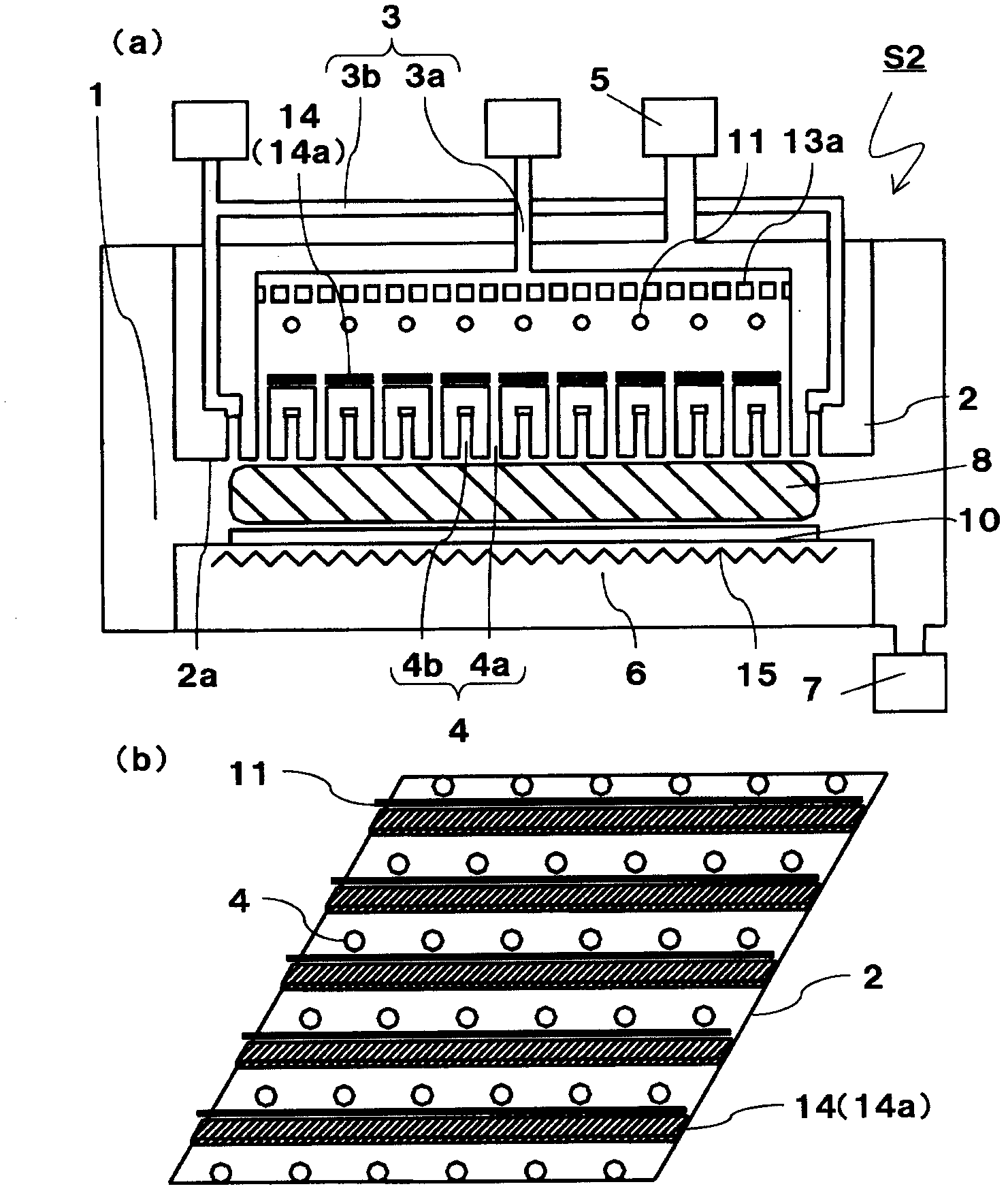

[0135] Next, compare the following three situations: the inside of the second electrode 2 made of stainless steel is provided with a cooling mechanism 14, and the cooling mechanism 14 has a situation in which the refrigerant is a lattice-shaped refrigerant path of silicone oil; 2, a cooling mechanism 14 is set inside the first electrode 6, and a base material heat dissipation unit 16 is set inside the first electrode 6, and the base material heat dissipation unit 16 has a case where the refrigerant is a grid-like refrigerant path of silicone oil; the cooling mechanism 14 and the base material dissipate heat Unit 16 is not set.

[0136] As the deposited film forming apparatus, an apparatus is prepared which is composed of the second electrode 2 and the first electrode 6, wherein the second electrode 2 has a function for supplying H 2 The first supply part 4a for gas (first raw material gas) and for supplying SiH 4 The second supply part 4b of gas (second raw material gas), the...

no. 2 example

[0144] Under the above-mentioned conditions A to E, respectively, on the substrate 10 made of glass having a transparent conductive film on the surface, a photoelectric conversion layer composed of an amorphous silicon film and having a pin junction is formed in order from bottom to top. The microcrystalline silicon film has a photoelectric conversion layer with a pin junction and a back electrode, thereby forming a double-layer thin-film solar cell, and comparing the power generation efficiency. At this time, the film thickness of the i-type amorphous silicon film is The film thickness of the i-type microcrystalline silicon film was 2.8 μm.

[0145] The photoelectric conversion layer made of an amorphous silicon film and the p-type and n-type microcrystalline silicon films were formed using a parallel plate type plasma CVD apparatus. In addition, the i-type microcrystalline silicon film was formed using a deposition film forming apparatus for heating a catalytic body under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com