Water cooling tower

A water cooling tower and water potential technology, applied in the direction of water shower coolers, engine components, machines/engines, etc., can solve problems such as limitations and neglect of potential energy, and achieve the effect of reducing cost and tower height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

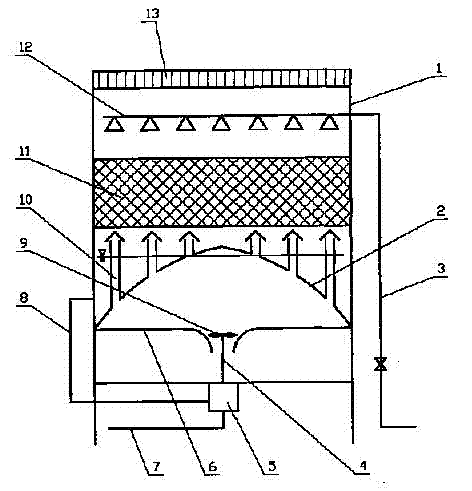

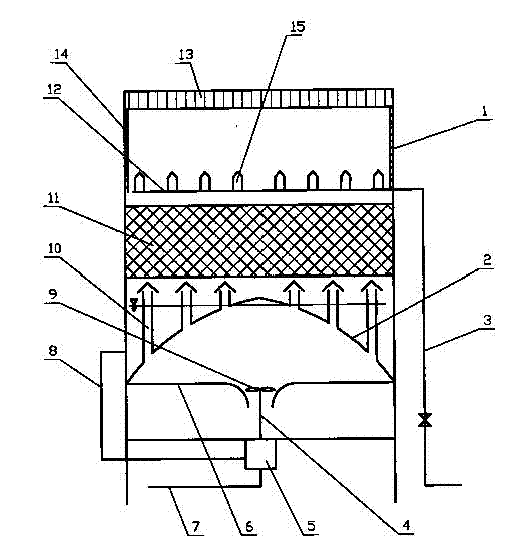

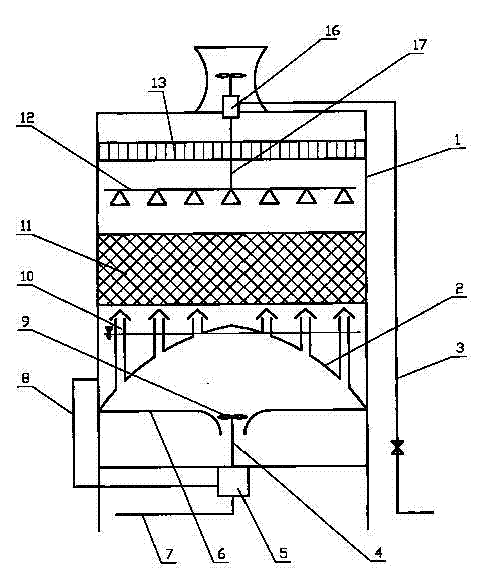

[0014] With reference to Fig. 1, the water energy self-cooling cooling water tower that the present invention provides, the upper end side of cooling water tower 1 is connected with the hot water inlet pipe 3 to be treated, and water inlet pipe 3 connects the water distribution pipe 12 of cooling water tower 1 inside, and above water distribution pipe 12 has Water eliminator 13, under the water distribution pipe 12 there is a water spraying packing layer 11, under the packing layer 11 there is an air-cooled distribution plate 2, the distribution plate 2 is equipped with a cap-shaped air distribution pipe 10, and the outlet pipe 8 is connected to a water outlet that uses the potential energy of the water outlet to drive , thereby driving the water energy machine 5 of the blower 9 to work, and the outside of the blower 9 has an air distribution enclosure 6. The water energy machine 5 is installed in the center of the bottom of the cooling tower 1, and its power output shaft 4 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com