Treatment method and treatment equipment for coking wastewater

A technology for coking wastewater and treatment equipment, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the separation and treatment of single fine resin, increase resin crushing and wear, resin Large amount of loss and other problems, to achieve the effects of small footprint, reduced resin loss, and short treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

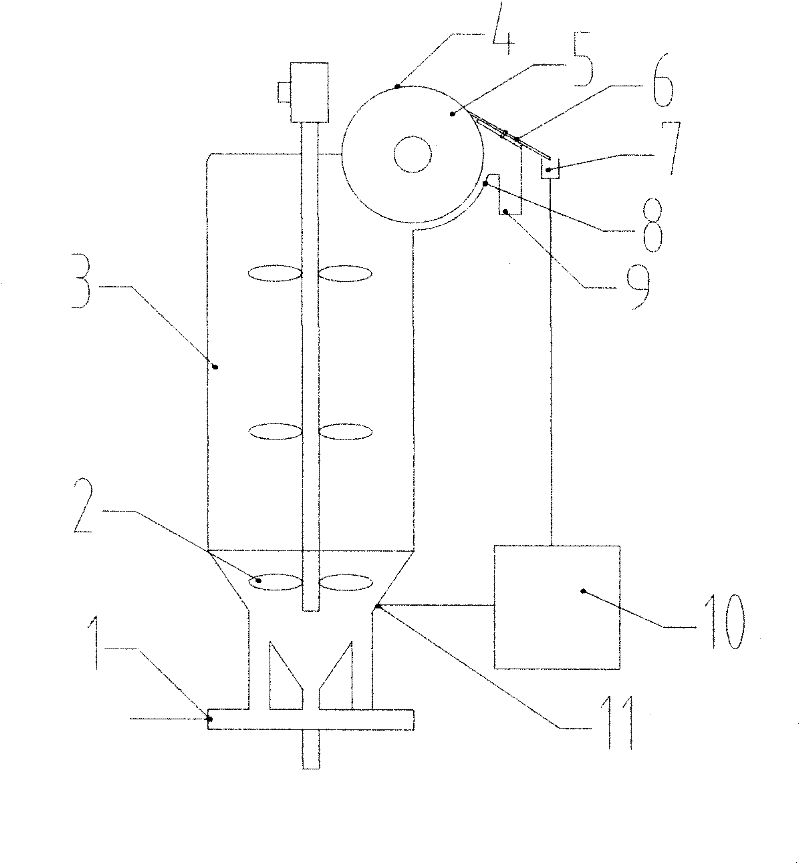

[0047] Such as figure 1 As shown, the magnetic resin adsorption reaction recovery device provided in this embodiment includes two parts, a columnar reactor 3 and a magnetic separation device 4. The upper part of the columnar reactor 3 is a cylinder, and the lower part of the columnar reactor 3 is a cone. Three layers of stirring blades 2 are arranged in the reactor, and the magnetic separation device 4 is on the upper part of the columnar reactor 3 . The magnetic separation device 4 is composed of a magnetic drum 5 , a slag scraping bar 6 and a slag discharge tank 7 . One end of the slag discharge tank 7 is connected with a magnetic resin regeneration device 10 . Three water inlets 1 are provided at the bottom of the columnar reactor 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com