Lifting method and lifting fastener for electrode with major diameter

A fastening device, large-diameter technology, applied in the direction of electric heating device, transportation and packaging, electrical components, etc., can solve the problem that it is not suitable for large-diameter electrode lifting and production use, the safety and reliability of production operations are reduced, and the use of roasting furnace equipment efficiency reduction and other issues, to achieve the effect of improving energy utilization, simple structure, increasing safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

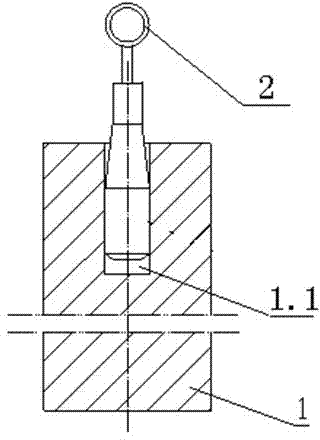

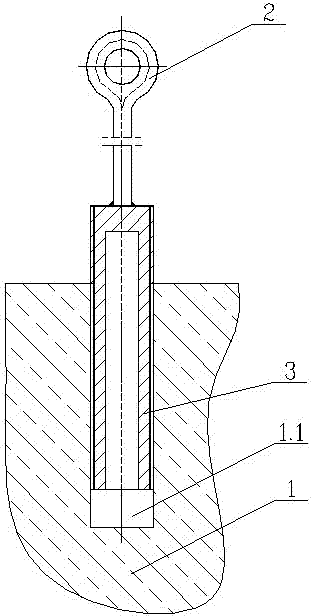

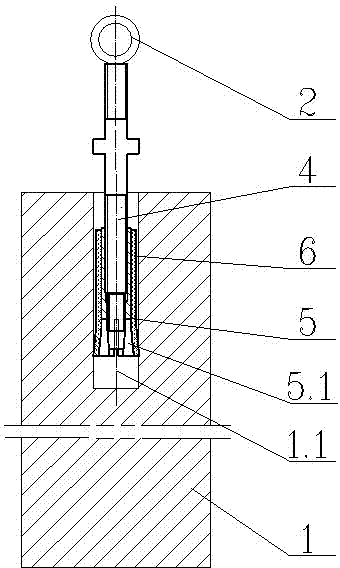

[0021] Embodiment 2 of the present invention: when the large-diameter electrode 1 is hoisted by means of hoisting equipment, a central hole 1.1 is made at the center of the large-diameter electrode 1, and the central hole 1.1 is made without threaded blind hole or light hole, and then a lifting fastening device that can be connected to the central hole is installed in the central hole 1.1 through a tight fit connection. The lifting fastening device can use a lifting fastening device of the present invention Expansive lifting fastenings for lifting large diameter electrodes (e.g. image 3 shown), the expansion-type lifting and fastening device includes a hanging ring 2, a threaded mandrel 4 is fixed at the lower end of the hanging ring 2, and a threaded mandrel 4 is threaded on which a large-diameter electrode 1 can be placed. The expansion tube 5 in the central hole 1.1 of the blind hole type makes an open expansion cone 5.1 at the bottom of the expansion tube 5, so that when ...

Embodiment 3

[0022] Embodiment 3 of the present invention: when using lifting equipment to lift the large-diameter electrode 1 by hanging, first make a central hole 1.1 at the center of the large-diameter electrode 1, and make the central hole 1.1 as a design There is a hole with a ring groove 1.2, and then a lifting fastening device that can be connected to the central hole 1.1 is installed in the central hole 1.1 through a buckle connection. The lifting fastening device can use a Snap-in lifting fastening device for lifting large diameter electrodes (such as Figure 4 and Figure 5 shown), the buckle-type lifting fastening device includes a hanging ring 2, a T-shaped bar 7 is fixed at the lower end of the hanging ring 2, and the arc-shaped boss 7.1 at the lower end of the T-shaped bar 7 can be buckled on the large In the annular groove 1.2 in the central hole 1.1 of the diameter electrode 1, during manufacture, the diameter of the central hole 1.1 of the large-diameter electrode 1 is la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com