Engine exhaust energy recovery device, ship provided therewith, and power generation plant provided with said engine exhaust energy recovery device

A technology for recycling devices and engines, which can be used in exhaust devices, mechanical equipment, engine components, etc., and can solve problems such as inability to improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

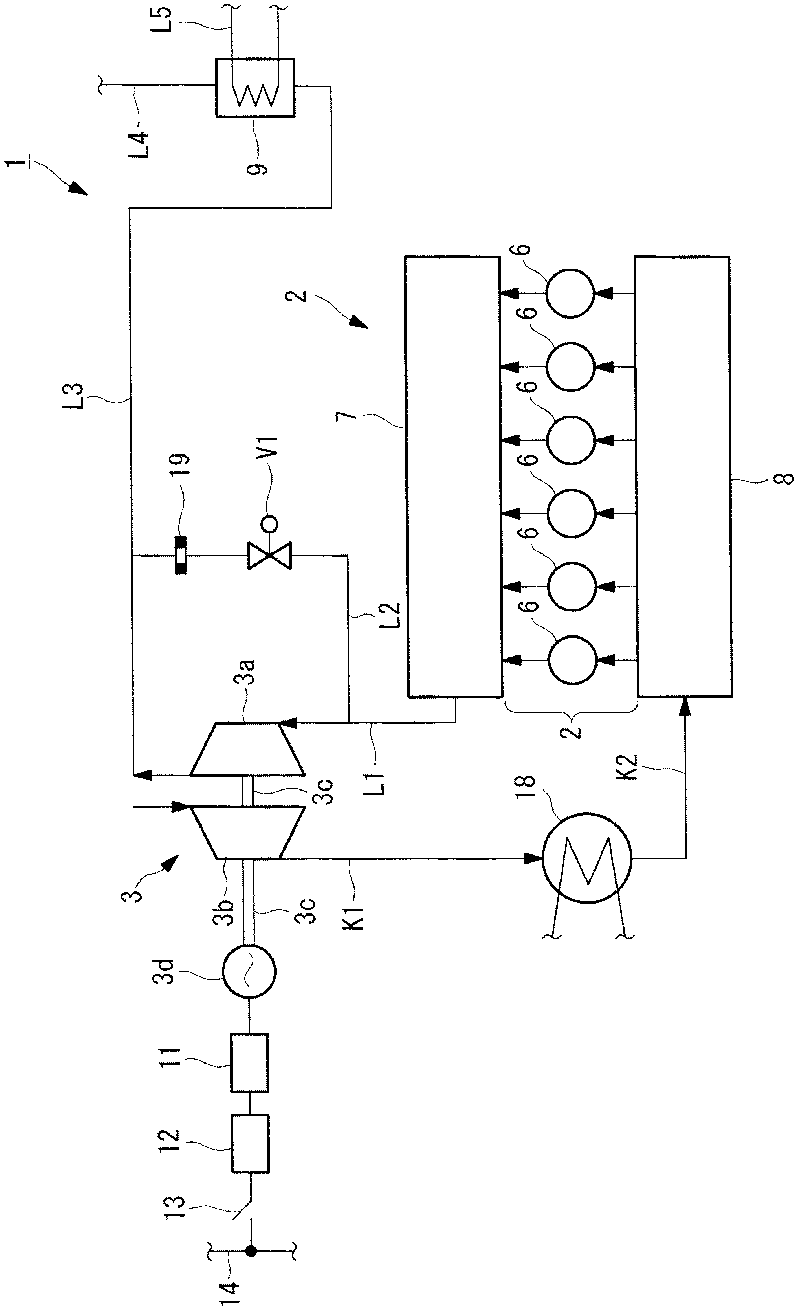

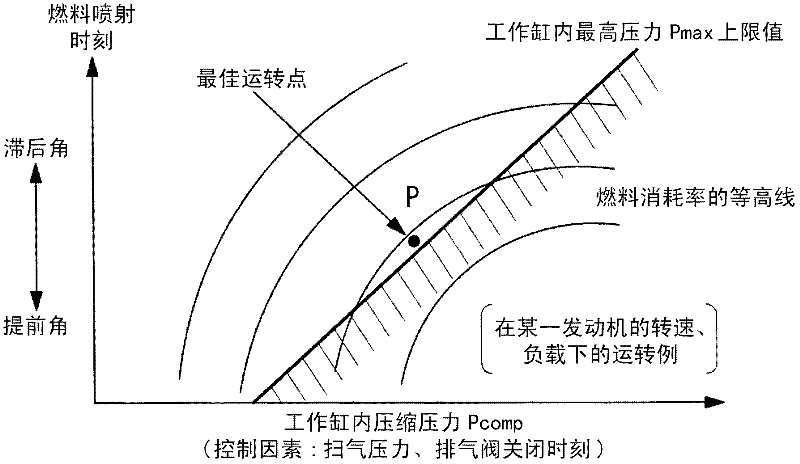

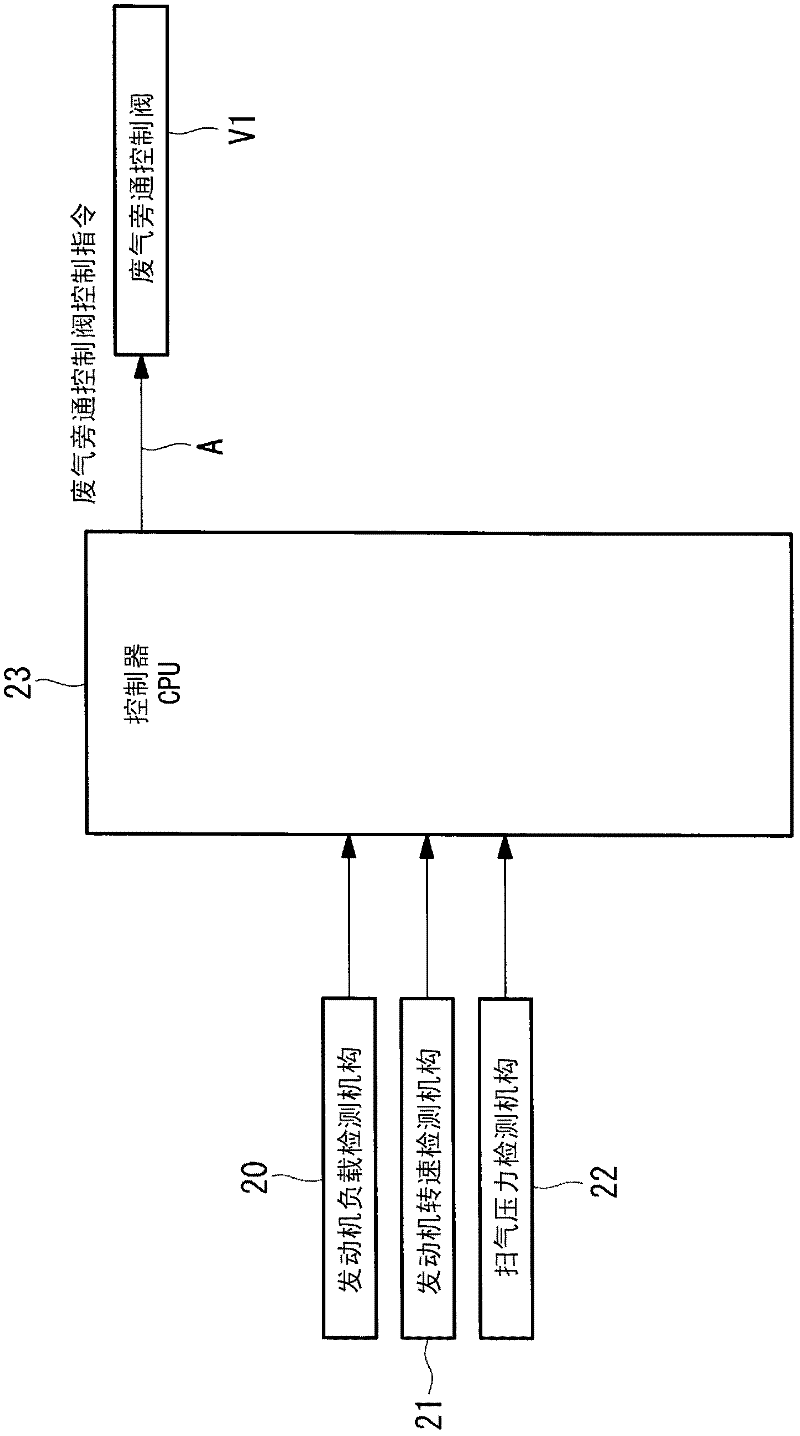

[0096] refer to image 3 and Figure 4 A first embodiment of the control method of the present invention for controlling the fuel consumption rate to a predetermined value or less will be described. image 3 is a control configuration diagram related to this embodiment, Figure 4 It is a control flowchart related to this embodiment.

[0097] exist image 3 , the engine main body 4 detected by the engine load detection mechanism 20 (refer to figure 1 ), the engine main body 4 rotational speed signal detected by the engine rotational speed detection mechanism 21, and the scavenging pressure signal detected by the scavenging pressure detection mechanism 22 are input to the controller (control device) 23. Based on the input signals, the controller 23 outputs a wastegate control valve control command signal A to the wastegate control valve V1.

[0098] Such as Figure 4 As shown, in step S1 , the signals of the engine load L, the engine speed Ne, and the scavenging pressure P...

no. 2 approach

[0113] Next, refer to Figure 5 and Figure 6 A second embodiment of the control method of the present invention for controlling the fuel consumption rate to a predetermined value or less will be described. In the first and second embodiments, the cylinder internal pressure is not measured, but the control is performed based on the scavenging pressure detected by the scavenging pressure detection means. On the other hand, in Embodiments 3 and 4 described later, it is the case where the control is performed to measure the pressure in the cylinder.

[0114] Figure 5 is a control configuration diagram related to this embodiment, Figure 6 It is a control flowchart related to this embodiment.

[0115] exist Figure 5 In the reference numerals, the same reference numerals are assigned to the same configuration, flow of exhaust gas, flow of air, and control method as those of the first embodiment. The control method differs from the first embodiment in that a wastegate valve ...

no. 3 approach

[0136] Next, refer to Figure 7 , Figure 8A and Figure 8B A third embodiment of the control method of the present invention for controlling the fuel consumption rate to a predetermined value or less will be described. Figure 7 is a control configuration diagram related to this embodiment, Figure 8A and Figure 8B It is a control flowchart related to this embodiment.

[0137] exist Figure 7 , Figure 8A and Figure 8B In the reference numerals, the same reference numerals are attached to the same structures as those of the second embodiment, the flow of exhaust gas, the flow of air, and the control method. The control method differs from the second embodiment in that the cylinder internal pressure signal detected by the cylinder internal pressure detection mechanism 27 is input to the controller 28 .

[0138] exist Figure 8A and Figure 8BIn step S21 of the shown flowchart, in addition to inputting the wastegate control valve opening degree signal B detected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com