Binder for ink-jet printing ink, ink-jet printing ink containing same, and printed matter

An inkjet printing and adhesive technology, applied in the field of inkjet printing inks and adhesives, can solve problems such as deterioration, floating and damage on the printing surface, and achieve the effects of excellent alkali resistance and excellent alcohol resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

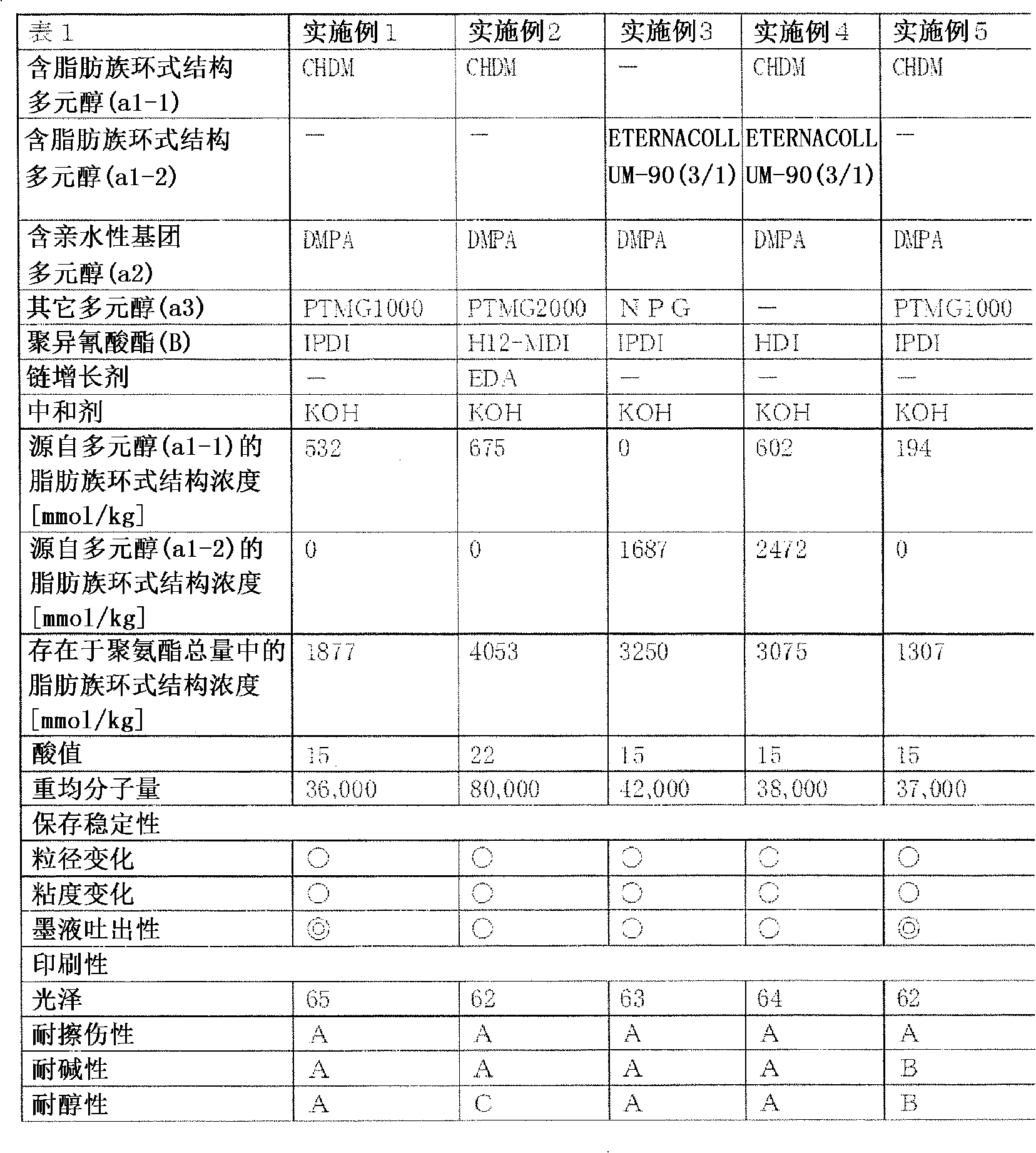

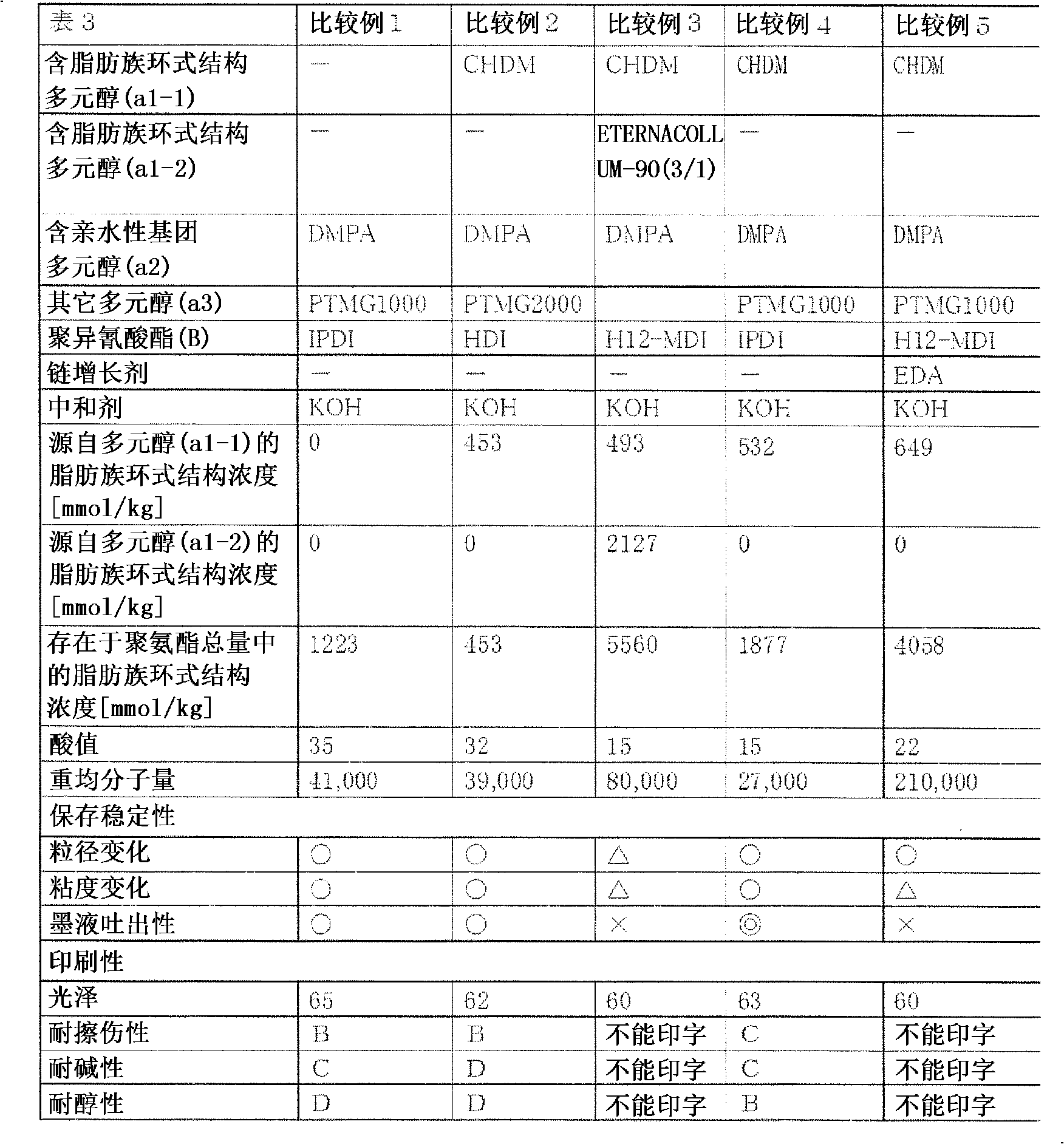

Embodiment 1

[0118] In a nitrogen-substituted container equipped with a thermometer, a nitrogen introduction tube, and a stirrer, polyether polyol ("PTMG1000" polyoxyl oxide manufactured by Mitsubishi Chemical Corporation) was prepared in the presence of 82.1 parts by mass of methyl ethyl ketone as an organic solvent. Tetramethylene glycol, number average molecular weight (1000) 143.5 parts by mass, 9.0 parts by mass of 2,2-dimethylolpropionic acid, 19.2 parts by mass of 1,4-cyclohexanedimethanol, and 74.8 parts by mass of isophorone diisocyanate The mass parts were reacted for 4 hours, and 50.5 mass parts of methyl ethyl ketone was added as a diluting solvent, and the reaction was continued.

[0119] When the weight-average molecular weight of the reactant reaches the range of 20000-50000, the reaction is terminated by adding 2.2 parts by mass of methanol, and 66.7 parts by mass of methyl ethyl ketone as a diluent solvent is added to obtain an organic solvent solution of polyurethane (acid...

Embodiment 2

[0123] In a nitrogen-substituted container equipped with a thermometer, a nitrogen introduction tube, and a stirrer, polyether polyol ("PTMG2000 "Polyoxytetramethylene glycol manufactured by Mitsubishi Chemical Corporation, number average molecular weight (2000) 117.9 parts by mass, 15.8 parts by mass of 2,2-dimethylolpropionic acid, 28.3 parts by mass of 1,4-cyclohexanedimethanol 128.9 parts by mass of dicyclohexylmethane diisocyanate and 128.9 parts by mass of dicyclohexylmethane diisocyanate were reacted for 6 hours, and 80.8 parts by mass of methyl ethyl ketone was added as a diluting solvent, and the reaction was continued.

[0124] When the NCO% remaining in the reactant reaches the theoretical value, cool to 50°C, add 11.9 parts by mass of triethylamine to neutralize part or all of the carboxyl groups of the above-mentioned polyurethane, then add 794.4 parts by mass of water and stir thoroughly , thus obtaining an aqueous dispersion of polyurethane.

[0125] 13.0 parts...

Embodiment 3

[0128] Polycarbonate diol ("ETERNACOLL UM-90 (3 / 1)" Copolycarbonate diol of 1,4-cyclohexanedimethanol and 1,6-hexanediol manufactured by Ube Industries, Ltd., number average molecular weight about 900) 130.6 parts by mass, 2,2-dimethylolpropane 9.0 parts by mass of acid, 19.9 parts by mass of neopentyl glycol, and 86.9 parts by mass of isophorone diisocyanate were reacted for 4 hours, and 82.1 parts by mass of methyl ethyl ketone as a diluent solvent was added to continue the reaction.

[0129] When the weight average molecular weight of the reactant reached the range of 20,000 to 50,000, the reaction was terminated by adding 2.6 parts by mass of methanol, and 52.2 parts by mass of methyl ethyl ketone as a diluent solvent was added to obtain an organic solvent solution of polyurethane.

[0130] Next, by adding 7.6 parts by mass of 48% by mass potassium hydroxide aqueous solution to the organic solvent solution of the above-mentioned polyurethane to neutralize part or all of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com