Laminated steel plate

A steel plate and core layer technology, applied in the direction of coating, layered products, metal layered products, etc., can solve the problems of light weight, high rigidity, impact resistance, processability, shape stability, etc., and achieve rigidity and durability high impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0067] [Constitution of laminated steel plates]

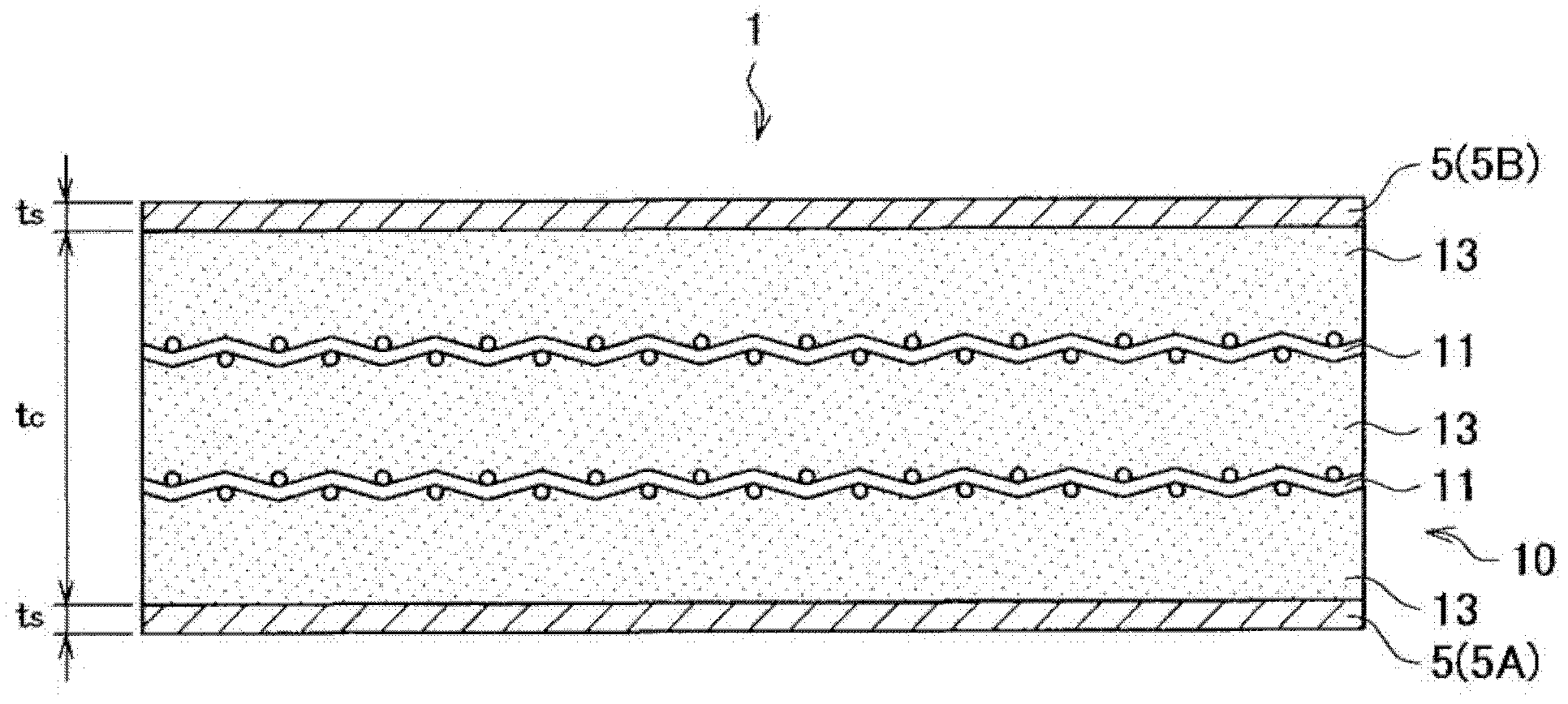

[0068] First, refer to figure 1 , the overall configuration of the laminated steel sheet according to the first embodiment of the present invention will be described. figure 1 It is a sectional view showing an example of the overall configuration of the laminated steel sheet 1 of the present embodiment.

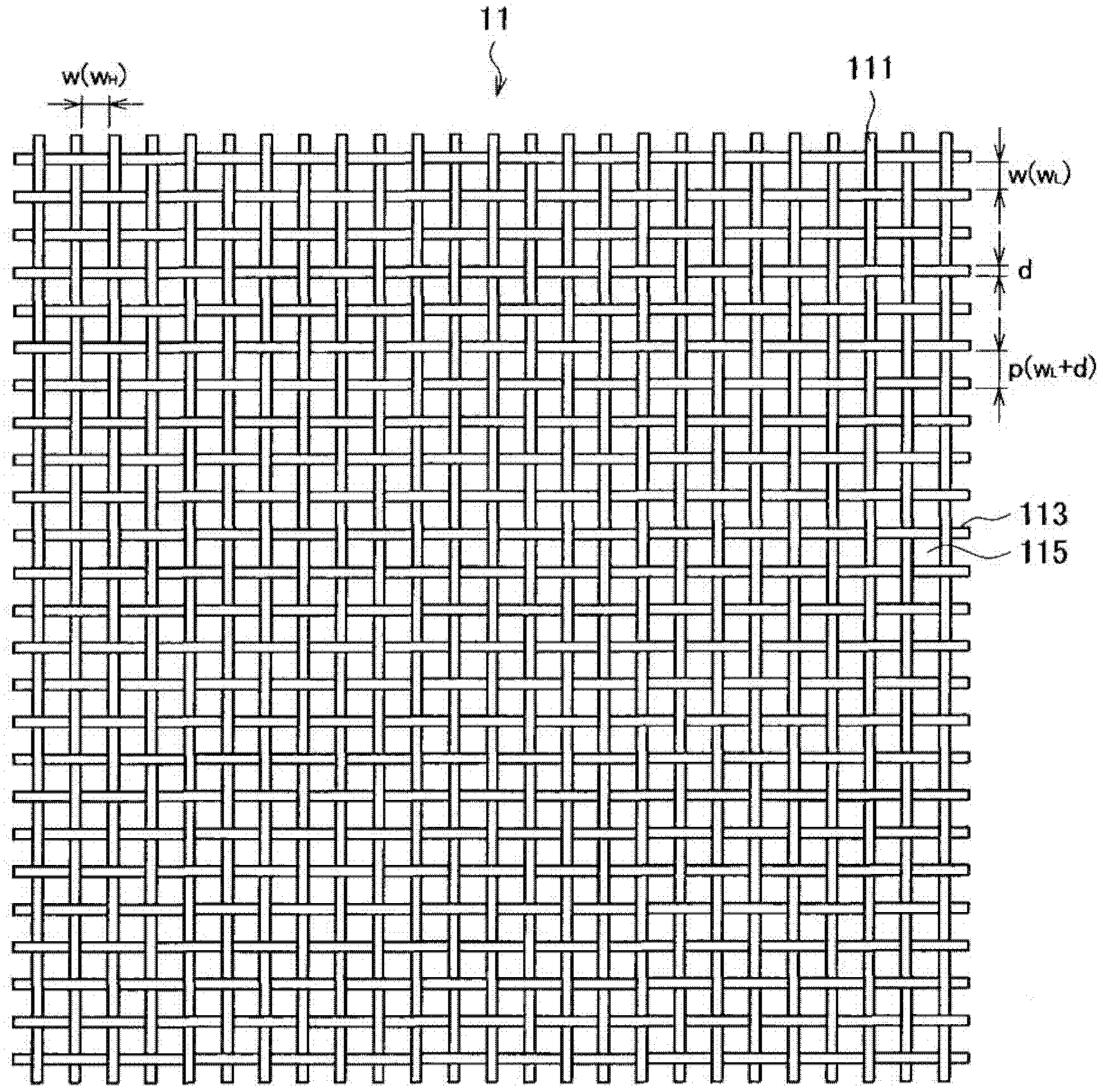

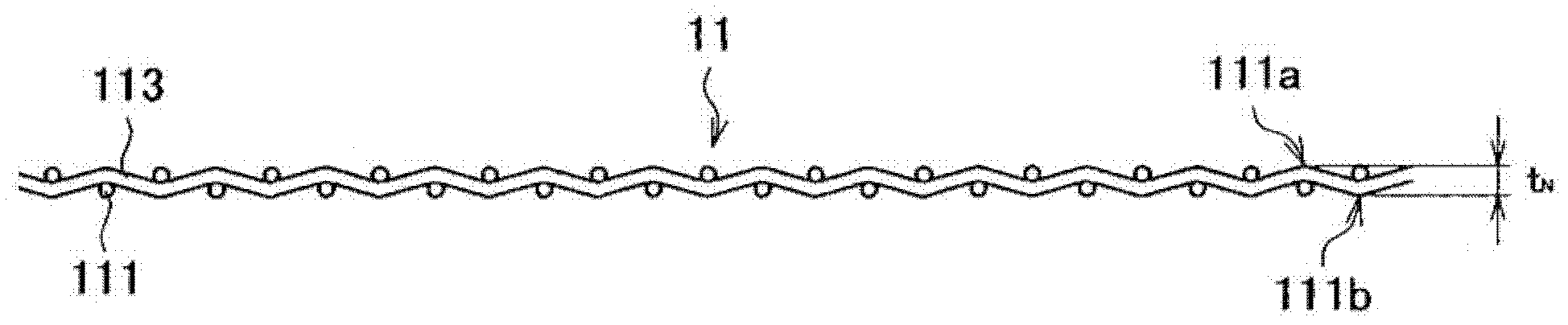

[0069] Such as figure 1 As shown, the laminated steel sheet 1 of the present embodiment has a structure in which steel sheets (hereinafter referred to as "surface layer steel sheets") 5 ( 5A, 5B) are respectively laminated on both surfaces of a core layer 10 . That is, the laminated steel sheet 1 has a structure in which the core layer 10 is laminated on the surface layer steel sheet 5A, and the surface layer steel sheet 5B is further laminated thereon. The core layer 10 is a layer composed of one or two or more netted wire groups 11 and one or two or more resin sheets 13 formed of a resin base material in a sheet shape. W...

no. 2 Embodiment approach

[0163] Next, refer to Figure 6 The overall configuration of the laminated steel sheet according to the second embodiment of the present invention will be described. Figure 6 It is a cross-sectional view showing an example of the overall configuration of the laminated steel sheet 2 of the present embodiment.

[0164] Such as Figure 6 As shown, the laminated steel sheet 2 of the present embodiment has a structure in which surface layer steel sheets 5 ( 5A, 5B) are respectively laminated on both surfaces of a core layer 10 , like the laminated steel sheet 1 of the first embodiment. That is, the laminated steel sheet 2 has a structure in which the core layer 10 is laminated on the surface layer steel sheet 5A, and the surface layer steel sheet 5B is further laminated thereon. As in the first embodiment, the core layer 10 is composed of one or more meshed wire group 11 formed of a mesh using wires and one or more resin sheets formed of a resin base material in a sheet shape. ...

no. 3 Embodiment approach

[0170] Next, refer to Figure 7 The overall configuration of the laminated steel sheet according to the third embodiment of the present invention will be described. Figure 7 It is a sectional view showing an example of the overall structure of the laminated steel plate 3 of this embodiment.

[0171] Such as Figure 7 As shown, the laminated steel sheet 3 of this embodiment has a structure in which surface layer steel sheets 5 ( 5A, 5B) are respectively laminated on both surfaces of a core layer 10 , like the laminated steel sheet 1 of the first embodiment. That is, the laminated steel sheet 3 has a structure in which the core layer 10 is laminated on the surface layer steel sheet 5A, and the surface layer steel sheet 5B is further laminated thereon. As in the first embodiment, the core layer 10 is composed of one or more meshed wire group 11 formed of a mesh using wires and one or more resin sheets formed of a resin base material in a sheet shape. A layer composed of mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com