Composition and process for production thereof

A composition and drug technology, applied in the direction of botanical equipment and methods, mixing methods, detergent compositions, etc., can solve the problems of unsatisfactory, air bubbles cannot exist stably for a long time, etc., achieve low manufacturing cost, safe and applicable , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

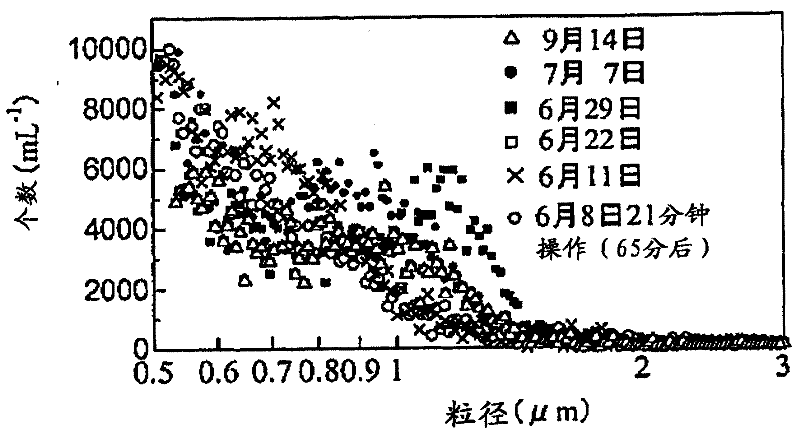

[0064] "BAVITAS" manufactured by Kyowa Co., Ltd. was used as an ultrafine bubble generating device utilizing a gas-liquid mixed shear method, and ultrafine bubbles were generated using pure water of 18.2 MΩ / cm. The particle size distribution at the time of generation and the change in the particle size distribution of bubbles after 3 months are shown in figure 1 middle. The measurement of the particle size distribution was performed using Multisizer 3 (manufactured by Beckman Coulter). No change in the number of bubbles in the portion having a particle diameter of 1 μm or less was observed.

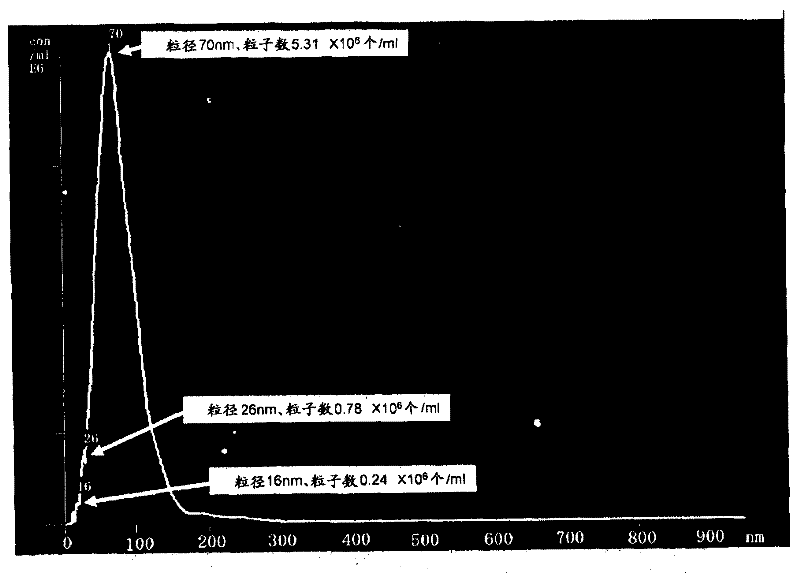

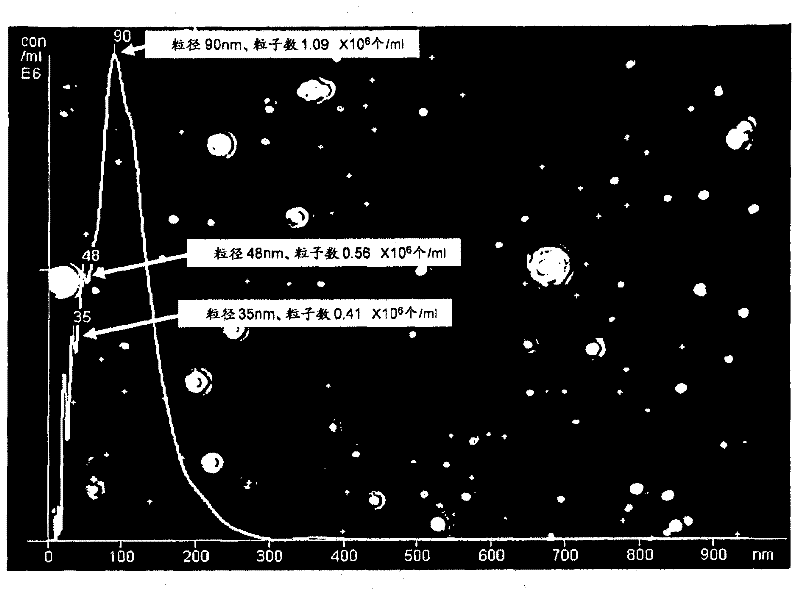

[0065] At the same time, the particle size of the generated ultrafine bubbles was measured with a nanoparticle analysis system NanoSight Series (manufactured by NanoSight Corporation). The measurement results are shown in figure 2 and image 3 middle. The horizontal axis of the figure represents the particle size in nm, and the vertical axis represents the number of particles per 1m...

Embodiment 2-5

[0068] The mixture having the composition shown in Table 1 below was treated under the same conditions as in Example 1 using "BAVITAS" manufactured by Kyowa Machinery Co., Ltd. Here, the water used is not pure water but distilled water. The results are shown in Table 1.

[0069] [Table 1]

[0070]

[0071] ※1 Micro-bubble generating device: "BAVITAS" manufactured by Kyowa Machinery Co., Ltd.

[0072] In Examples 2-4, drugs exhibiting hydrophobicity were stably dispersed. Both the drug stored at room temperature (RT) and the drug stored at 40°C maintained a good emulsified state.

[0073] Figure 5-13 shows the results of measuring the particle size distribution of the dispersions obtained in Examples 2-4 immediately after preparation and after storage at room temperature and 40° C. using a particle size distribution measuring device LS 13 320 (manufactured by Beckman Coulter Co., Ltd.). The abscissa represents the particle diameter, and the volume % (upper graph) and n...

Embodiment 6-8

[0077] As the samples used in Examples 6-8, the components shown in the following Table 2 in parts by weight were sequentially blended and treated under the same conditions as in Example 1 using "BAVITAS" manufactured by Kyowa Corporation. However, the water used is not pure water but distilled water.

[0078] Surfactants were used in Comparative Examples 2 and 3, and volatile components were emulsified in the same manner as in Examples 6 and 7. In addition, in Comparative Example 4, the same drug as in Example 8 was dissolved in a homomixer.

[0079] [Table 2]

[0080]

[0081] 1: "BAVITAS" established by Concorde Co., Ltd.

[0082] 2: Thiabendazole

[0083] 3: Water-soluble plant extract

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com