Double-reed amalgam component for electrodeless lamp

A technology of electrodeless lamp and amalgam, which is applied in the field of new lighting lamps and lanterns, and can solve problems such as tilting and tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

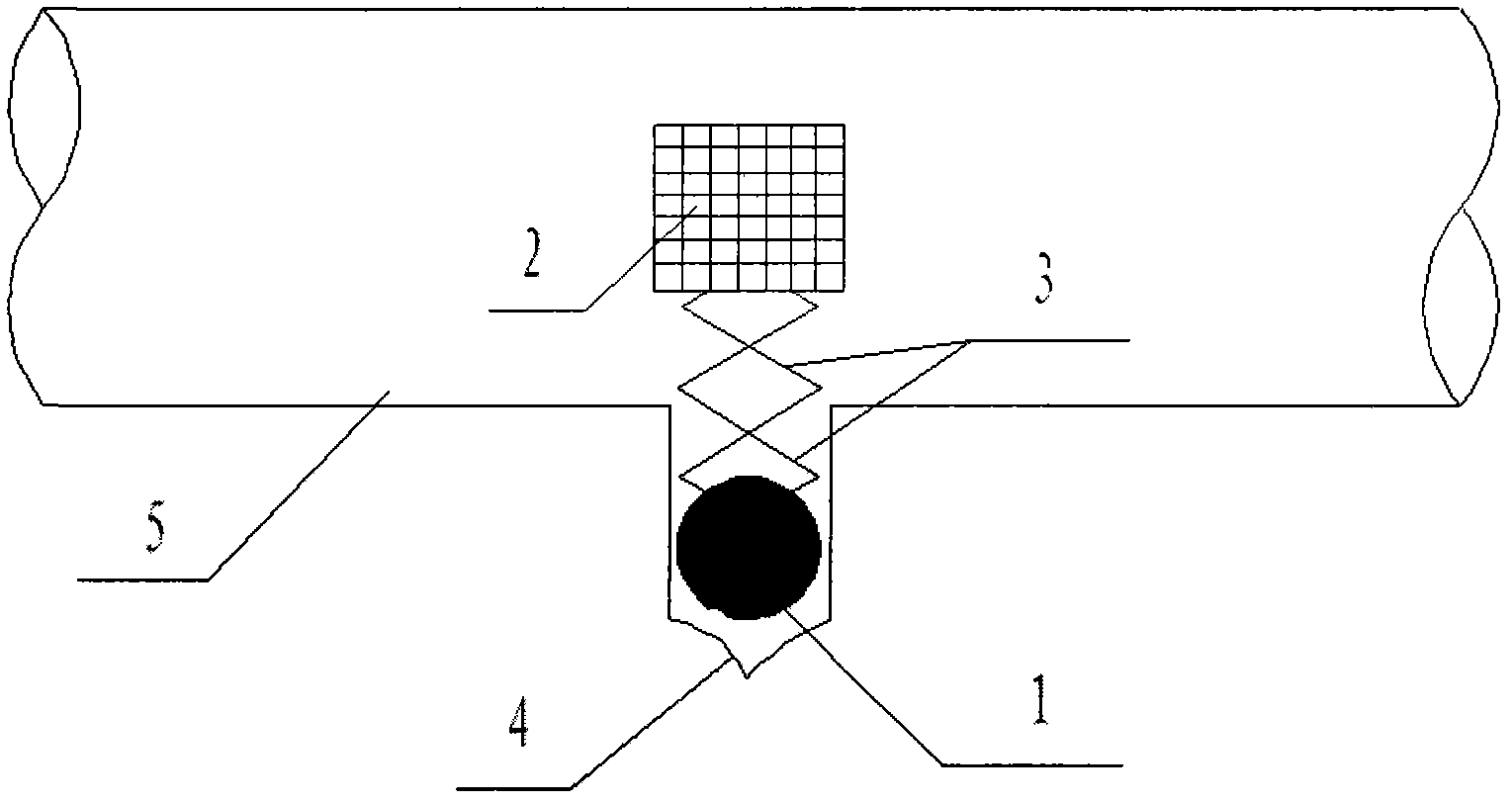

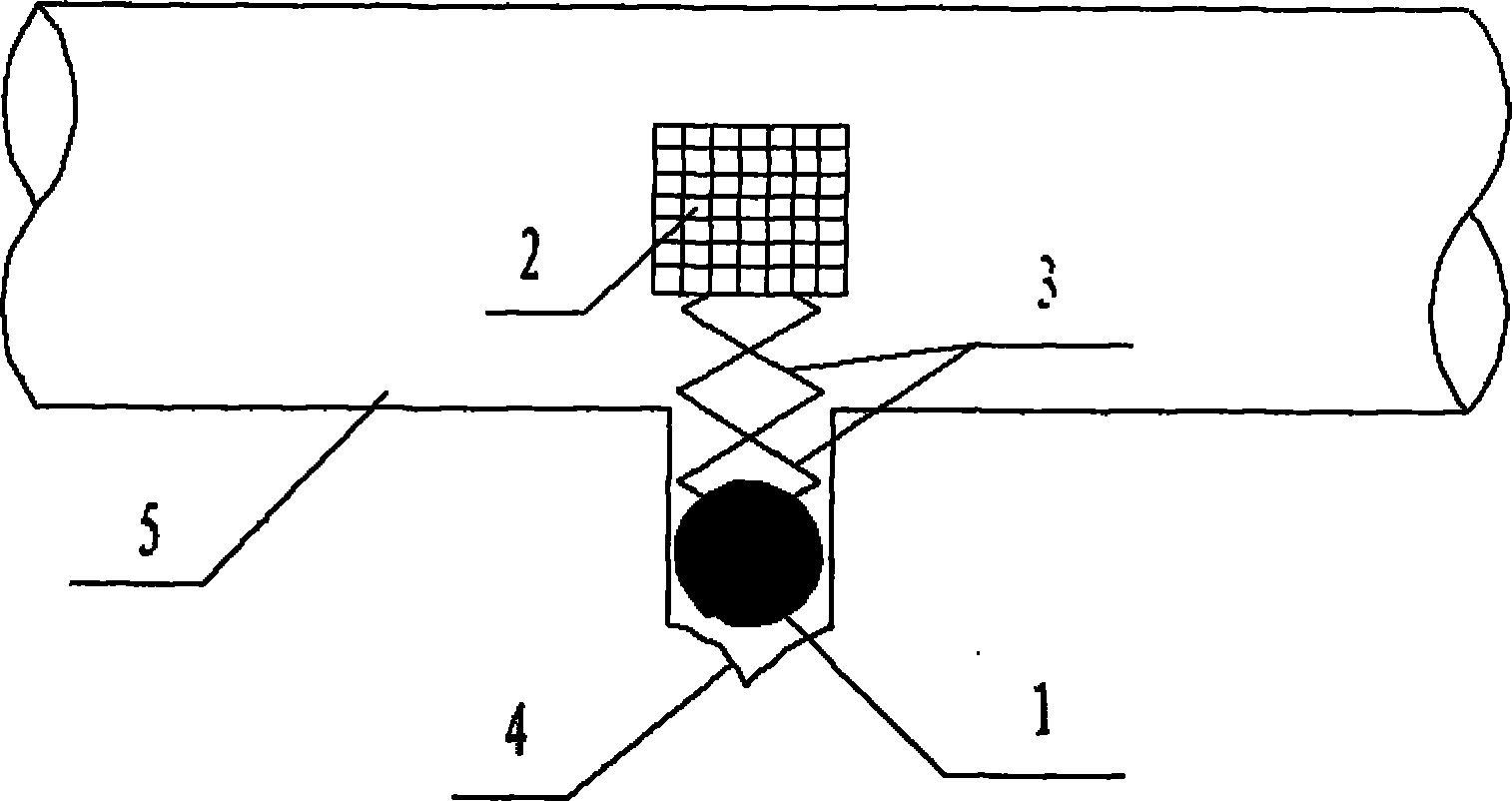

[0011] Such as figure 1 As shown, the double-reed amalgam assembly for the electrodeless lamp includes a main amalgam (solid mercury) 1, an auxiliary amalgam (indium mesh) 2, a double spring 3 composed of two compression springs, and an exhaust pipe 4. It is characterized in that: the main The amalgam (solid mercury) 1 and the auxiliary amalgam (indium net) 2 are connected by double springs 3. Due to the radial tension of the double springs expanding in the circumferential direction, the amalgam assembly stands firmly in the exhaust pipe, and the auxiliary amalgam Qi (indium net) 2 just can not tilt, askew.

[0012] In addition to the above-mentioned embodiments, the present invention can also have other implementations. All technical solutions formed by equivalent replacement or equivalent transformation fall within the scope of protection required by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com