Method for testing linewidth uniformity

A test method and uniformity technology, applied in the field of line width uniformity test, can solve problems such as the inability to truly reflect the performance of the lithography machine lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

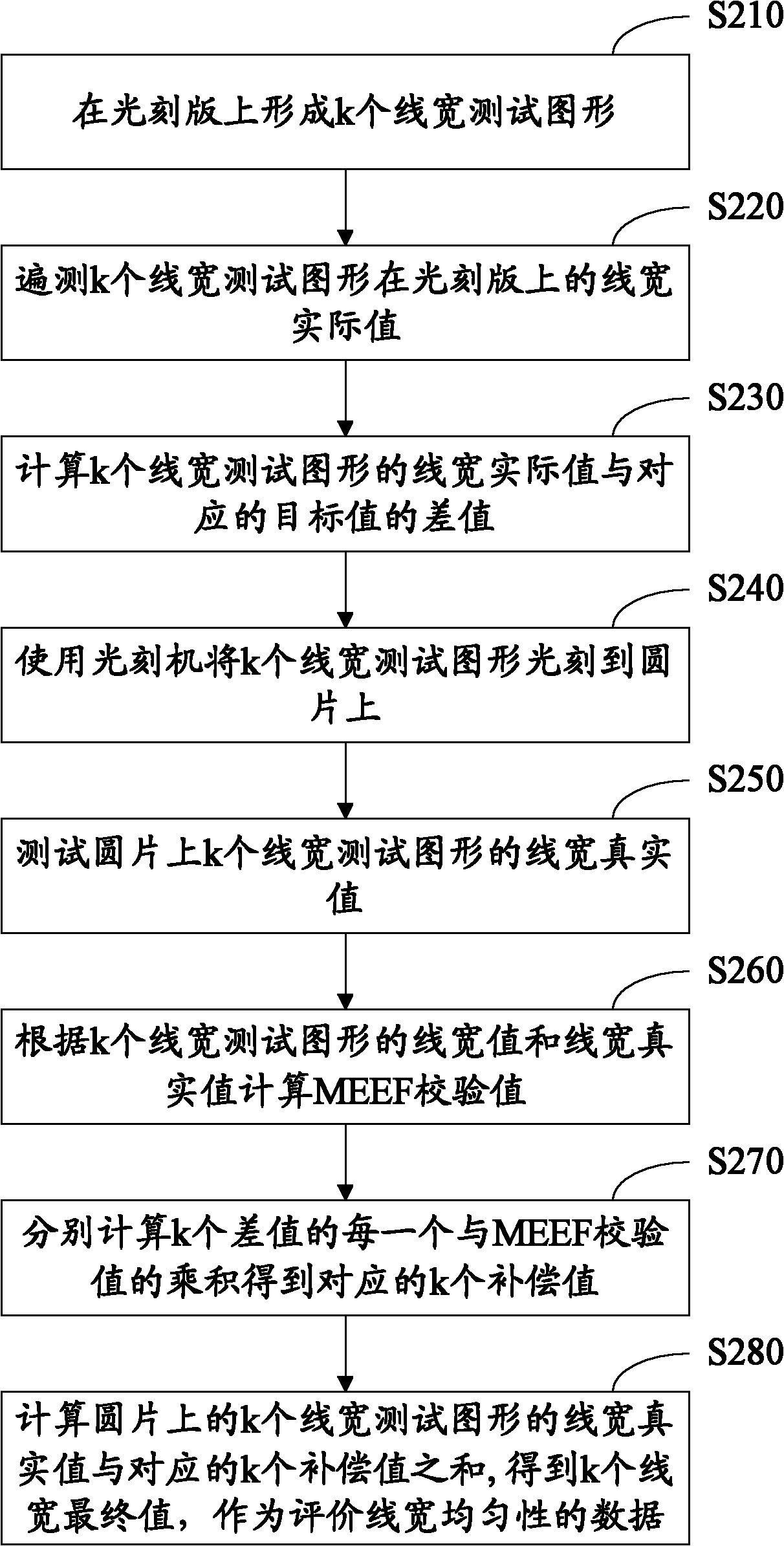

[0021] The present invention utilizes the principle of MEEF (mask error enhancement factor, lithographic plate error enhancement factor) to obtain a test method for line width uniformity with simplified test steps. figure 2 It is a flow chart of a test method for line width uniformity in an embodiment, comprising the following steps:

[0022] S210, forming k line width test patterns on the photolithography plate.

[0023] The design value of the uniformly distributed line width on the photolithography plate is the target value A 1 、A 2 ,...,A k k line width test patterns, k is a natural number.

[0024] In this embodiment, each line width test pattern includes two line width figures, and these two line width figures are inverse patterns (that is, the translucent and opaque parts are just opposite), so as to meet different types of tests. Requirements, that is, to test the bar structure and to test the spacing between each bar structure. In a preferred embodiment, each li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com