Preparation method of hydroxyapatite nano grain

A technology of hydroxyapatite and nanocrystalline particles, which is applied in chemical instruments and methods, pharmaceutical formulations, phosphorus compounds, etc., can solve the problems that cannot meet the requirements of human tooth enamel tissue size and structure, small order range of materials, and limited size and structure. Gap and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add calcium nitrate (0.3mol / L), calcium chloride (0.2mol / L), disodium hydrogen phosphate (0.3mol / L), collagen (20g / L), and a mixed solvent of ethanol and water ( 2:1), adding sodium hydroxide solution to adjust the pH to 11, and reacting at a constant temperature in a water bath, the reaction temperature is 60° C., and the reaction time is 5 hours.

[0028] (2) Take out the reacted mixed solution and transfer it to a sealed stainless steel reaction kettle lined with polytetrafluoroethylene to synthesize through hydrothermal reaction.

[0029] (3) The intermediate product was washed three times with water, filtered, and freeze-dried to obtain the final product.

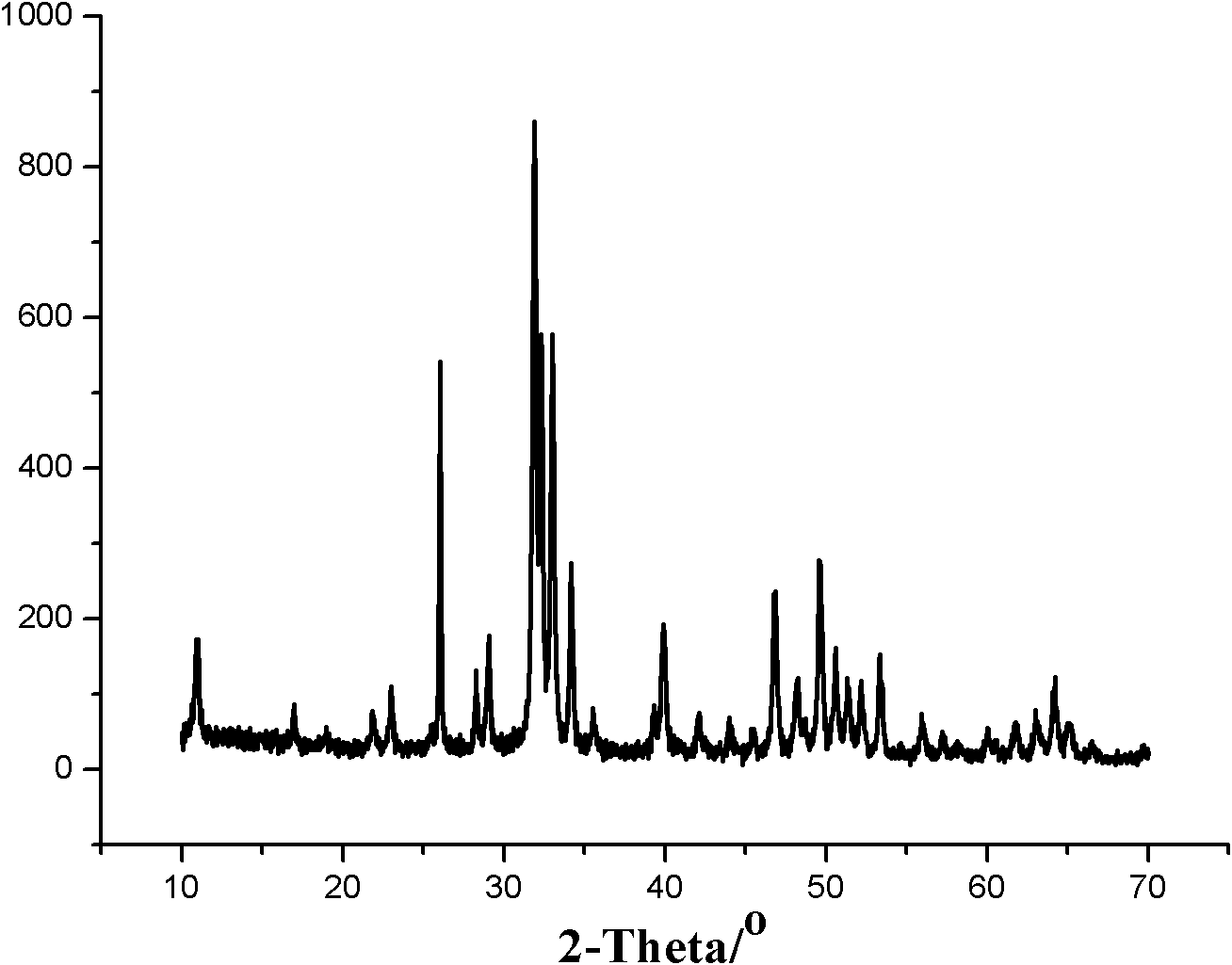

[0030] The resulting product was characterized by XRD and SEM tests figure 1 and figure 2 .

[0031] figure 1 It is the XRD spectrum of the hydroxyapatite nanocrystals obtained in Example 1. It can be seen that it has a typical peak shape of hydroxyapatite, and is a hydroxyapatite nanocrystal; figure ...

Embodiment 2

[0033] (1) Calcium nitrate (1mol / L), dipotassium hydrogen phosphate (0.4mol / L), disodium hydrogen phosphate (0.2mol / L), gelatin (40g / L), add ethanol and water mixed solvent (1 : 2), adding sodium hydroxide solution to adjust the pH=11, and reacting at a constant temperature in a water bath, the reaction temperature is 40° C., and the reaction time is 3 hours.

[0034] (2) Take out the reacted mixed solution and transfer it to a sealed stainless steel reaction kettle lined with polytetrafluoroethylene to synthesize by hydrothermal reaction. The hydrothermal reaction temperature is 160° C., keep warm for 48 hours, and take out the intermediate product.

[0035] (3) The intermediate product was washed three times with water, filtered, and freeze-dried to obtain the final product.

[0036] After testing, the obtained product is hydroxyapatite nano crystal grains, which are in the bundle structure formed by rod-shaped nano crystals arranged in parallel, similar to the tooth prism str...

Embodiment 3

[0038] (1) Calcium nitrate (0.1mol / L), dipotassium hydrogen phosphate (0.04mol / L), disodium hydrogen phosphate (0.02mol / L), gelatin (5g / L), and a mixed solvent of ethanol and water ( 1:4), adding sodium hydroxide solution to adjust the pH=10, and reacting at a constant temperature in a water bath, the reaction temperature is 20° C., and the reaction time is 24 hours.

[0039] (2) Take out the reacted mixed solution and transfer it to a sealed stainless steel reactor lined with polytetrafluoroethylene inside to synthesize by hydrothermal reaction. The hydrothermal reaction temperature is 100° C., keep it warm for 100 hours, and take out the intermediate product.

[0040] (3) The intermediate product was washed three times with water, filtered, and freeze-dried to obtain the final product.

[0041] After testing, the obtained product is hydroxyapatite nano crystal grains, which are in the bundle structure formed by rod-shaped nano crystals arranged in parallel, similar to the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com