Cover plate device for maintaining engine on rear side surface of cab shell

A cover plate device, cab technology, applied in the directions of superstructure, transportation and packaging, sub-assembly of the superstructure, etc., can solve the problems of high manufacturing cost, waste of time, inconvenient disassembly and assembly, etc. The effect of cost reduction and process saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail with reference to the accompanying drawings and specific embodiments.

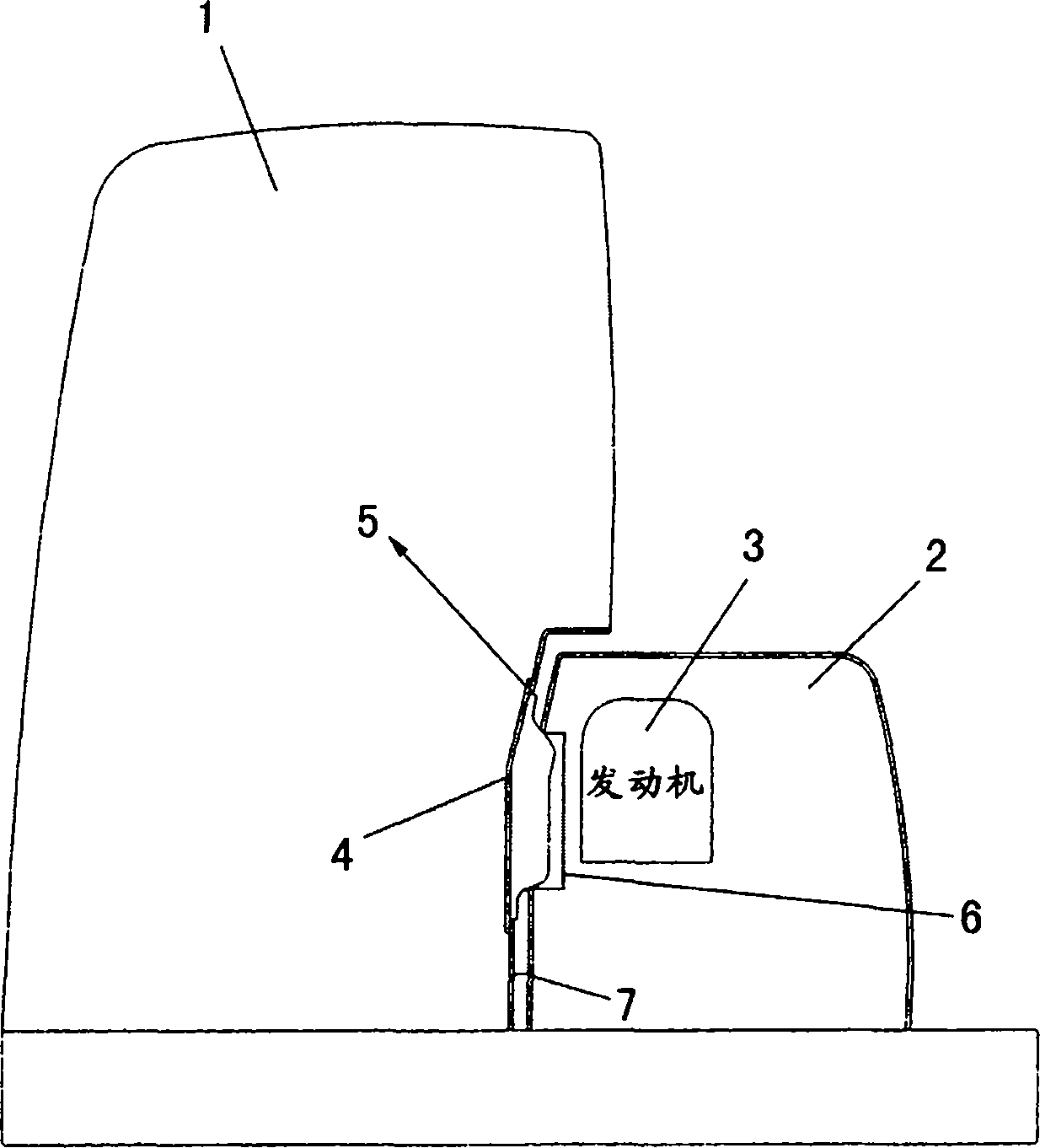

[0031] figure 1 For the installation diagram of the cab cover device used for maintaining the engine provided by the present invention, the description of each reference numeral in the figure is as follows: cab housing 1, engine housing 2, engine 3, cover device 4, first Opening 5, second opening 6, distance 7 between cab housing and engine housing.

[0032] Such as figure 1 As shown, the present invention provides a cover plate device that is detachably installed on the rear side of the cab casing and used for maintaining the engine, wherein the rear of the cab casing 1 is provided with an engine casing 2. The engine 3 is installed inside the space formed by the engine casing 2, the rear side of the cab casing 1 is opposite to the front side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com