Double-layer filter material dust remover

A double-layer filter material and dust collector technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of complex maintenance management, fragmentation, inability to use high temperature resistant materials with processability, etc., to achieve maintenance management. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

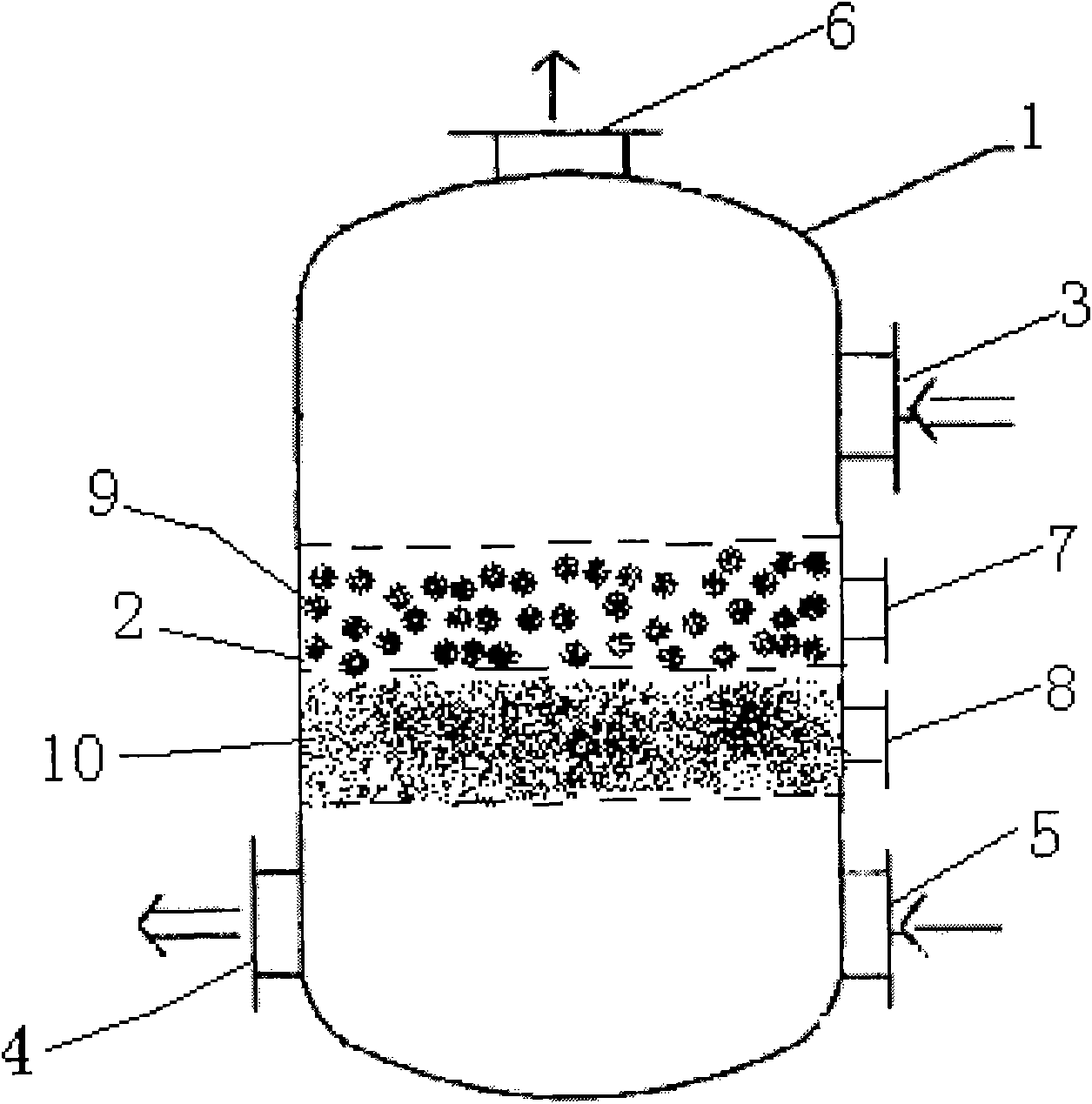

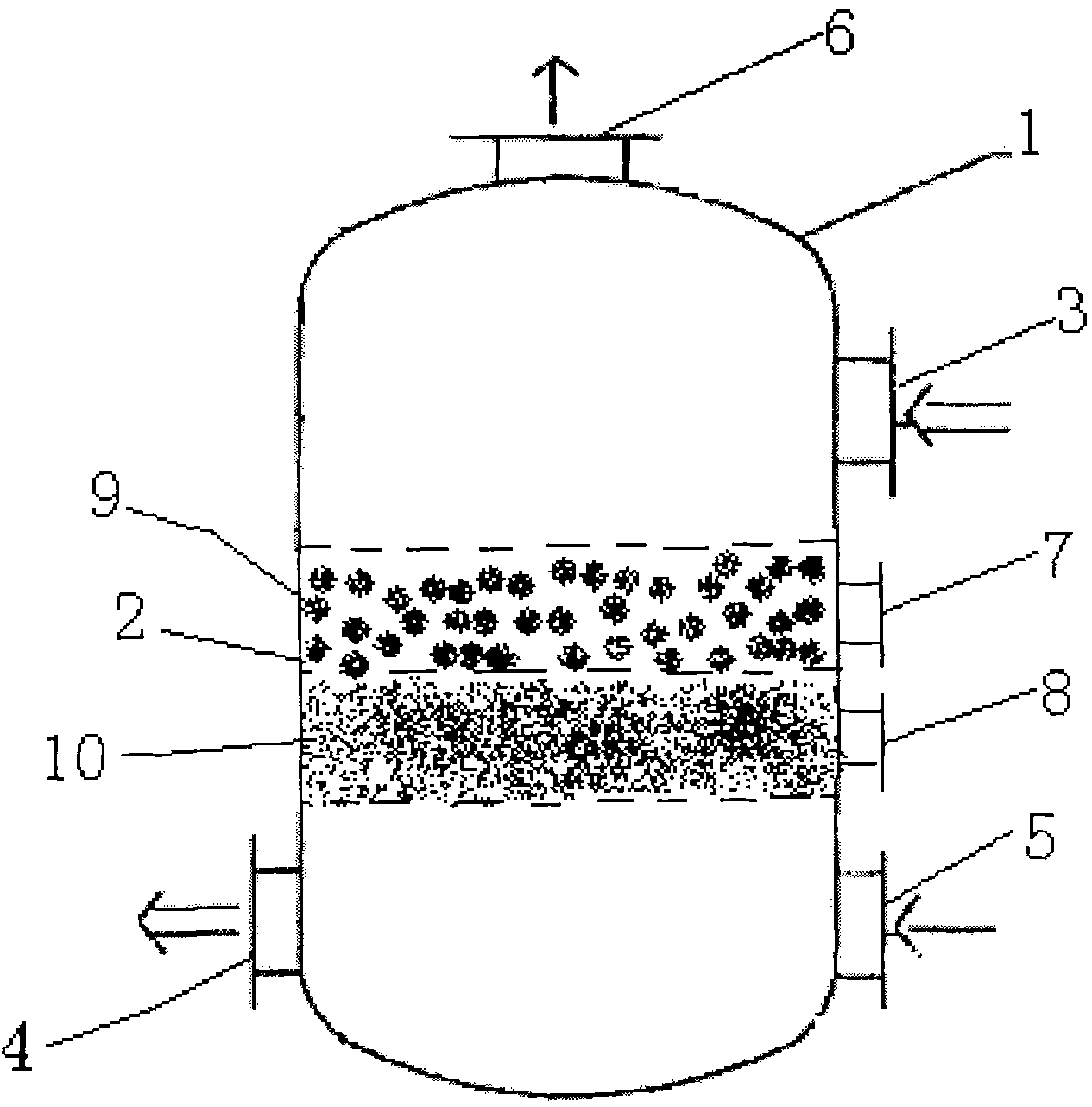

[0010] Specific embodiment: the double-layer filter dust collector of the present invention includes a housing 1, a filter layer 2 located in the housing 1, a dust-laden gas inlet 3, a purified gas outlet 4, a back-blowing gas inlet 5, and a back-blowing gas outlet 6. There are 7 inlets and outlets for the upper filter material, and 8 outlets for the lower filter material.

[0011] The filter layer 2 is composed of a double-layer filter material with a light top and a heavy bottom, and a thick top and a fine bottom. The upper filter material 9 is expanded perlite particles with a particle size of 2mm and a bulk density of 70kg / m3; the lower filter material 10 is sea sand. The diameter is 0.8mm, and the bulk density is 1500kg / m3. When filtering, the dust-laden gas passes through the filter layer 2 from top to bottom, first passes through the upper filter material 9 of coarse particles, intercepts most of the dust in the gas, and then passes through the lower filter material 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com