Heat shield element arrangement comprising screw threading means and method for installing a heat shield element

A technology of components and bolts is applied in the field of heat shield component devices to achieve the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

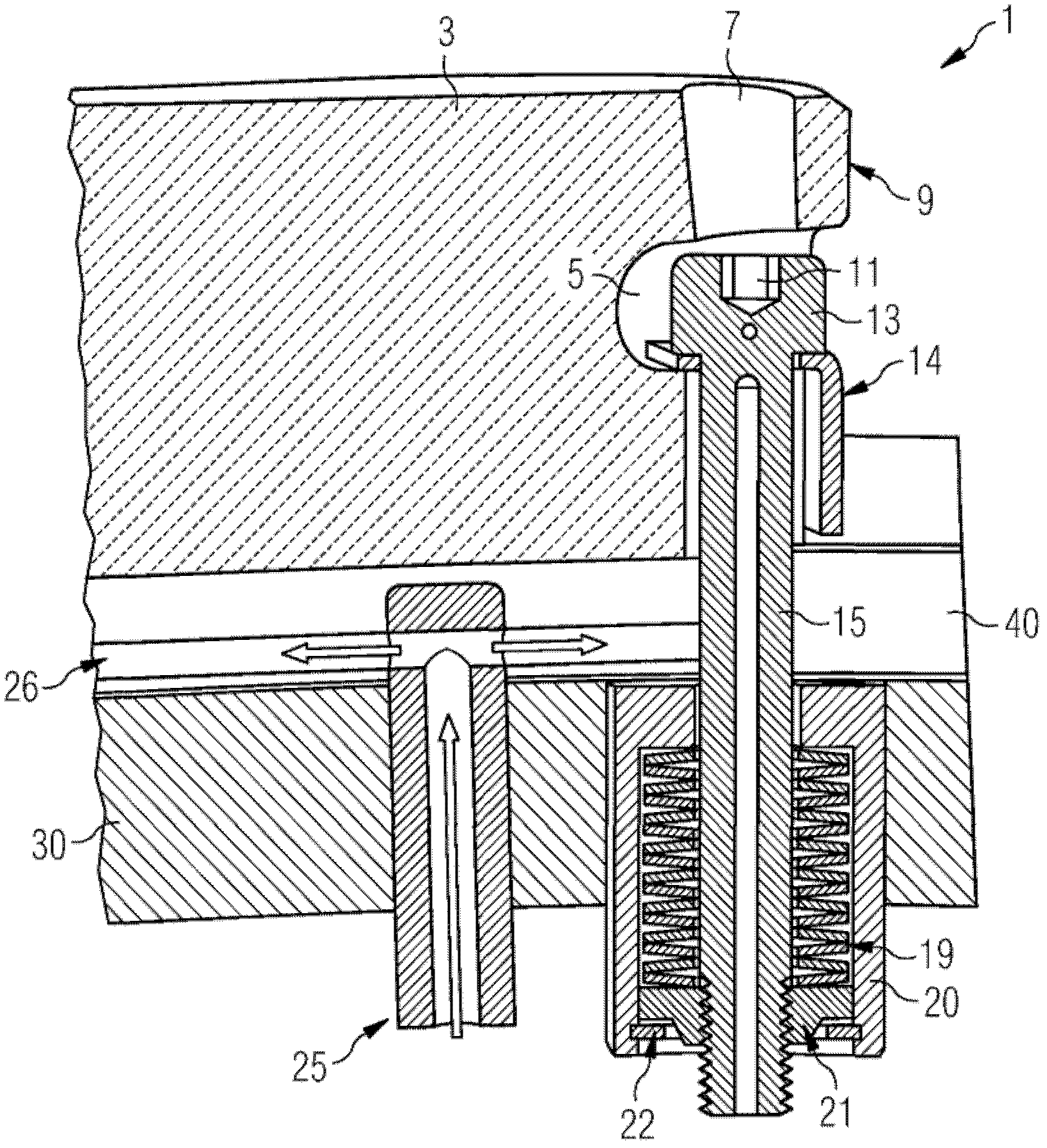

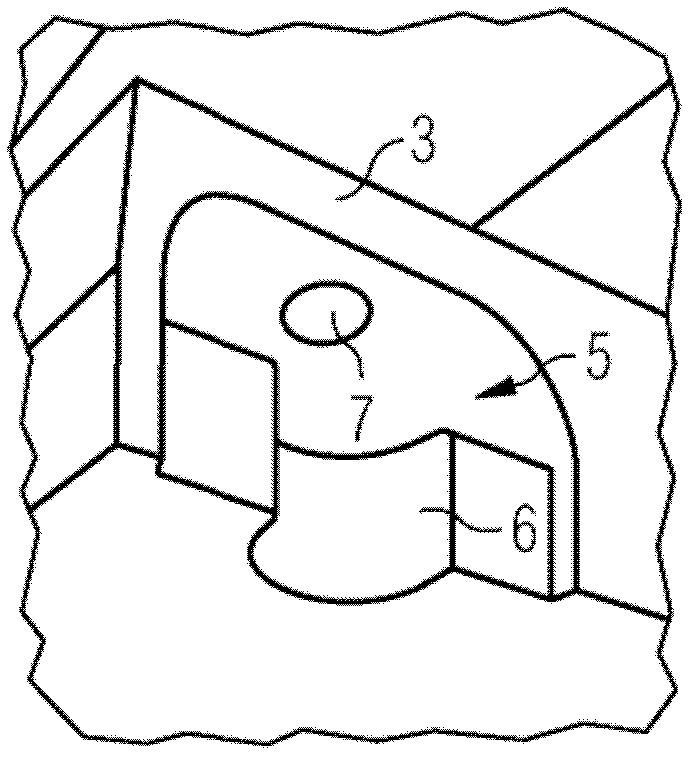

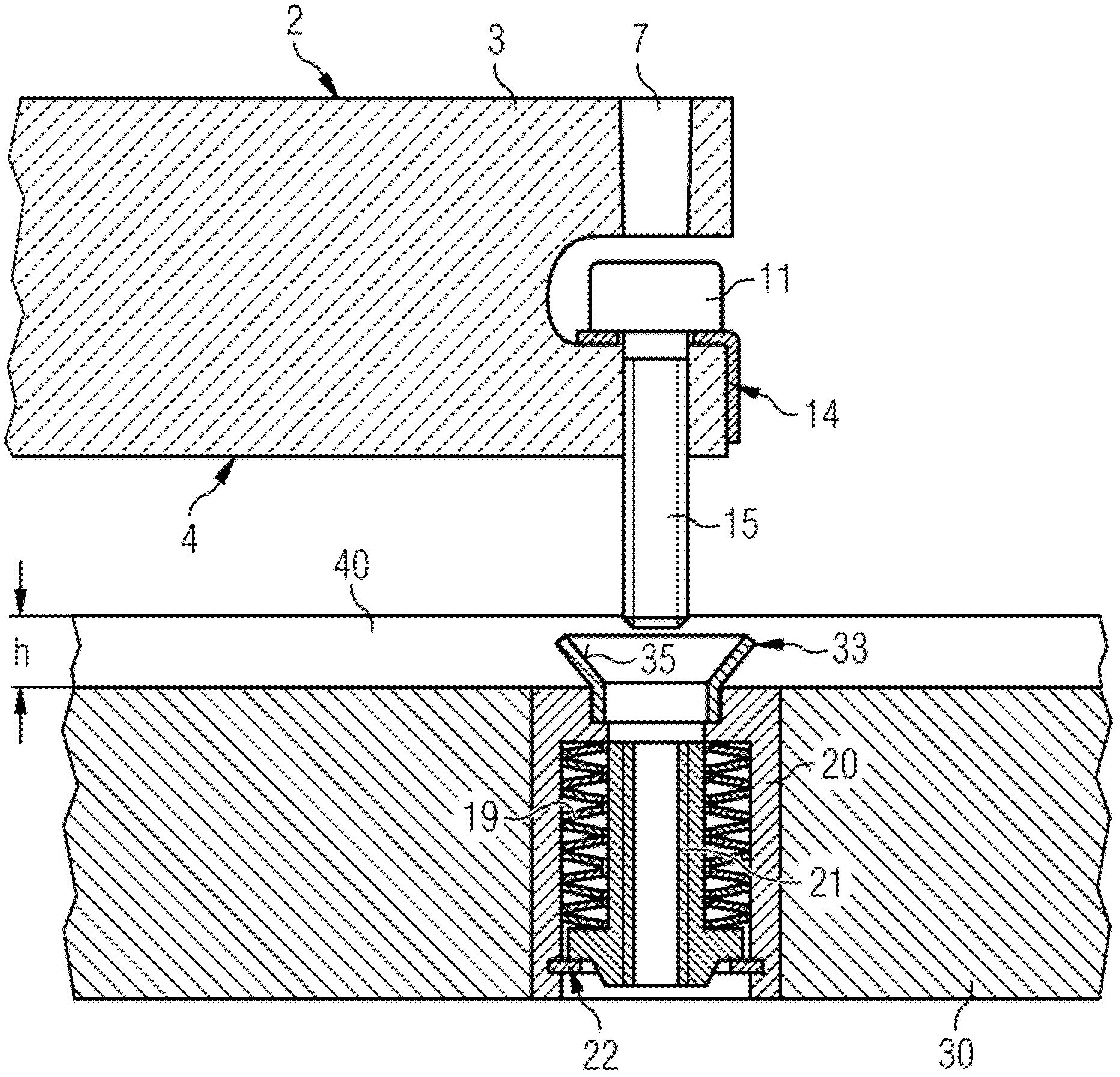

[0028] figure 1 and figure 2 A partial cross-sectional view of a known heat shield element arrangement 1 is shown.

[0029] In the known heat shield element arrangement 1 , the heat shield elements 3 or so-called bricks are fastened to the support structure 30 by means of a total of four screw connections. This relates in particular to vault tiles or samples of heat shield elements.

[0030] Formed in the sides of the heat shield element 3 are recesses or pockets 5 with side recesses 6 into which a screw 15 and a nut 13 can be inserted from the side. Below the screw cap 13 there is a pressure divider or washer 14 which distributes the pressure over a larger area and thus protects the ceramic body of the heat shield element 3 .

[0031] According to the prior art, the heat shield element 3 with all four installed bolts 15 and the voltage divider 14 must now be installed vertically in the support structure 30, the four screw rods 15 must penetrate into four correspondingly l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com