Cable connector assembly

一种线缆连接器、组件的技术,应用在连接、连接装置的零部件、电气元件等方向,能够解决线缆连接器组件整体高度高等问题,达到结构小型化、降低整体高度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

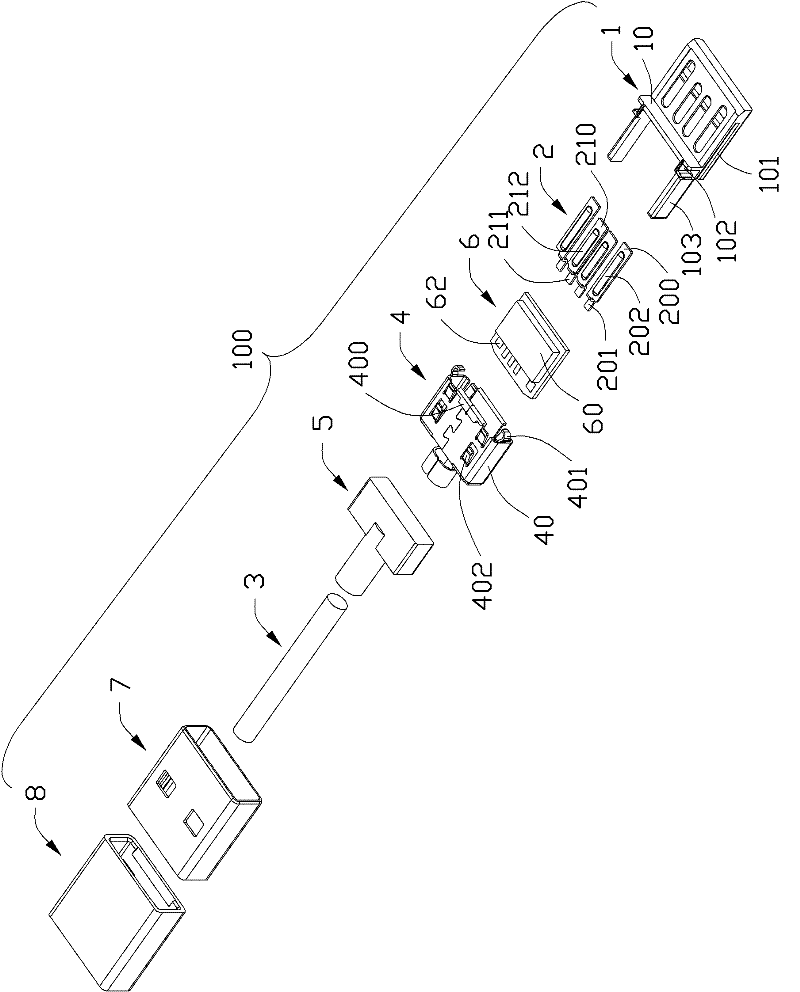

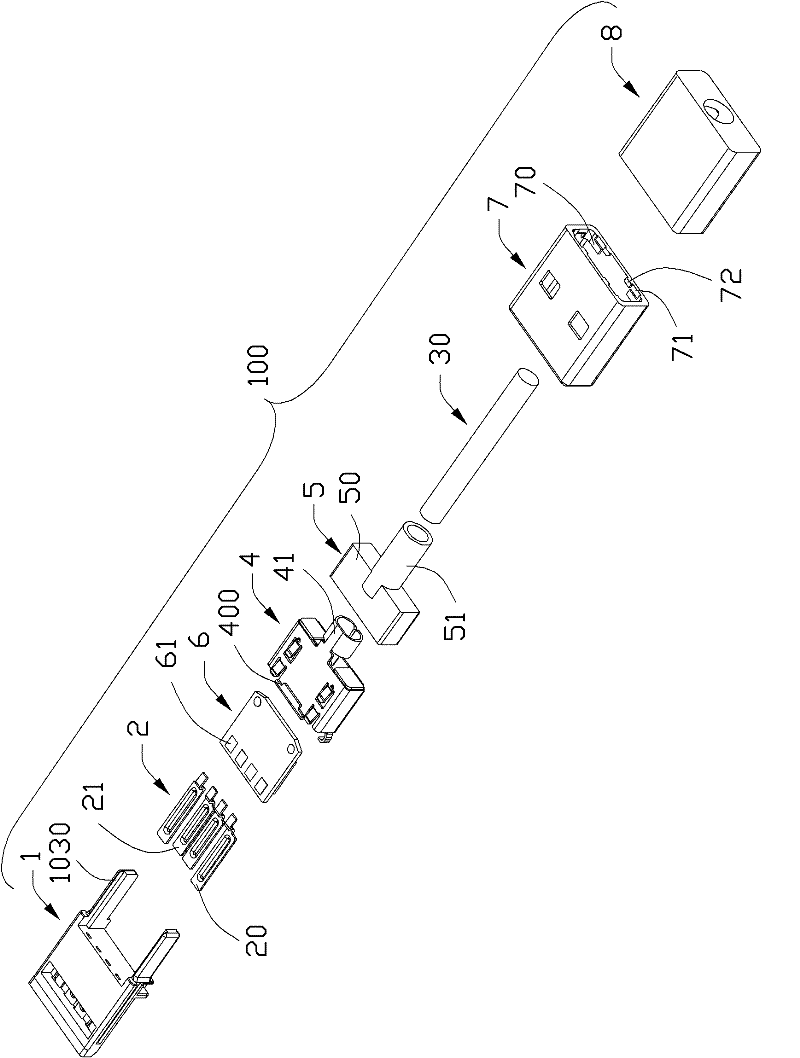

[0015] The cable connector assembly 100 of the present invention includes a conductive terminal 2, an insulating body 1 formed on the periphery of the conductive terminal 2, a printed circuit board 6 electrically connected to the conductive terminal 2, and an assembly assembled on the insulating body 1. Shield housing 7 .

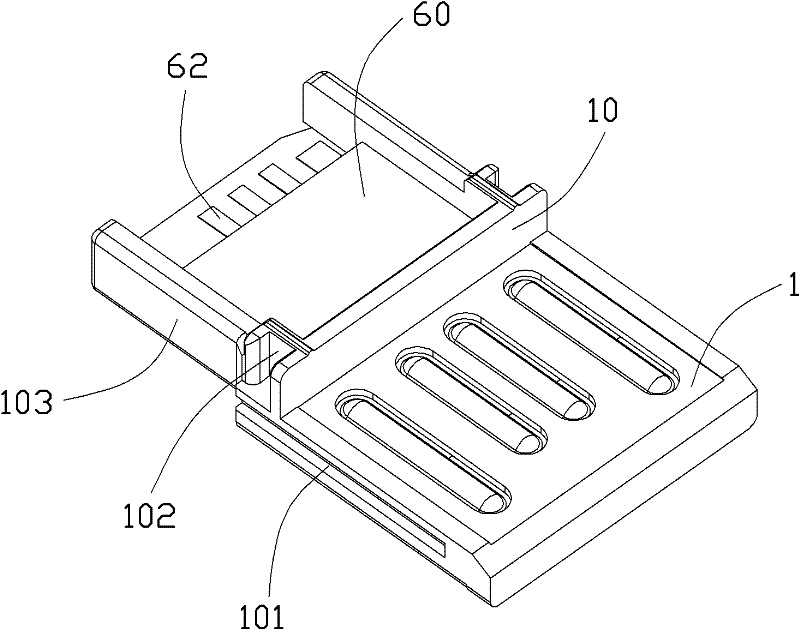

[0016] Please refer to Figure 1 to Figure 2 As shown, the insulating body 1 is roughly in the shape of a cuboid, and a groove 101 extending along the front and rear directions is respectively provided on the left and right sides of the insulating body 1, and protrudes upward from the rear direction of the upper surface of the insulating body 1. A baffle 10 is provided from the top, and a cantilever 103 is formed extending backward from both sides of the rear surface of the baffle 10, and an opening 102 coplanar with the rear surface of the baffle 10 is provided on the cantilever 103, The rear surface of the opening 102 is higher than the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com