Oil sleeve joint sealing and detecting device

A technology of sealing detection and detection device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problem of reducing the contact pressure of the sealing surface and not having the composite load of internal pressure and external pressure. The test ability and detection method cannot meet the needs of downhole working conditions, etc., to achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

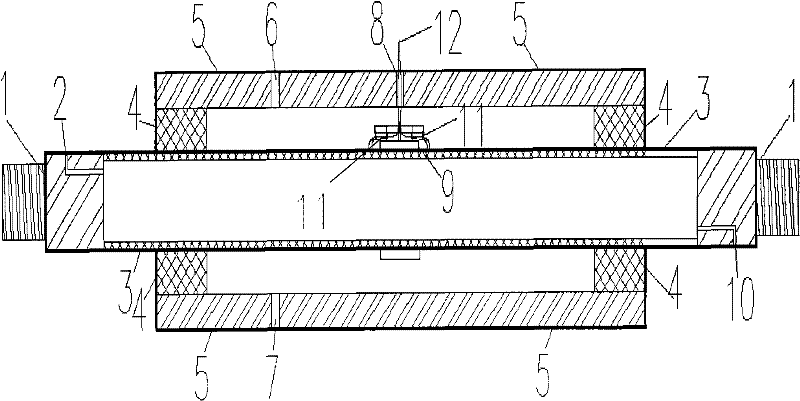

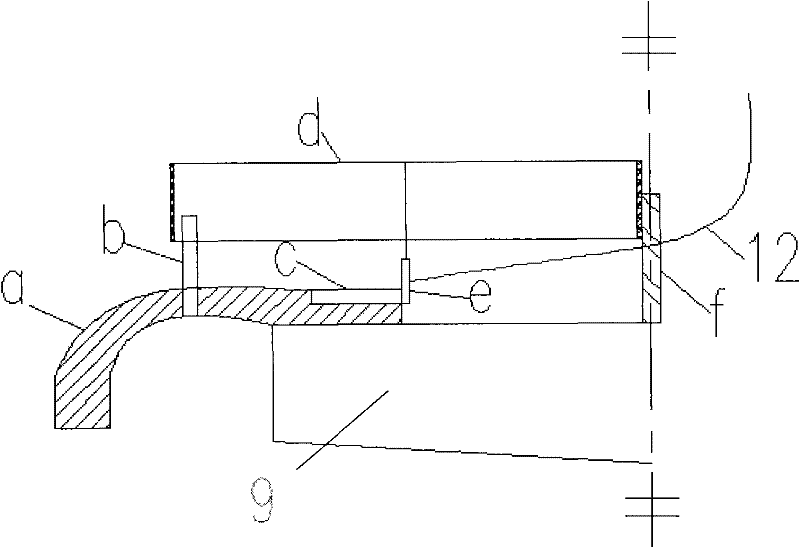

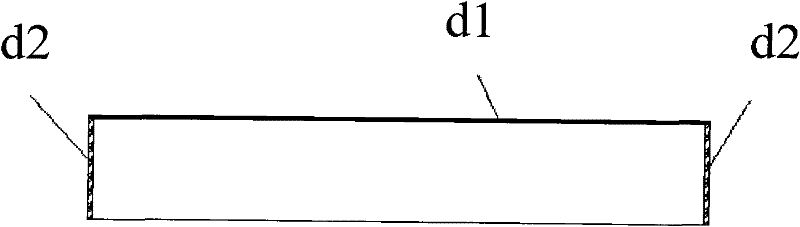

[0020] see figure 1 , a sealing detection device for oil-casing joints, comprising an external pressure container 5 and a stretching auxiliary rod 1, the two ends of the external pressure container 5 are provided with sealing plugs 4, and the sealing plugs 4 are used to pass through the outer surface of the sample 3. Seal the end of the external pressure container 5 after the pressure container 5, so that the middle of the sample 3 is in a sealed space; the internal pressure leakage rate detection device 11 is provided inside the external pressure container 5, and the internal pressure leakage rate detection device 11 is used for testing. For the internal pressure of sample 3, the external pressure container 11 is provided with a third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com