Method for oil refinery sewage classification control and grading treatment

A technology for oil refining sewage and control and classification, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. or cascaded use, not considering the issue of differentiated treatment of other pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

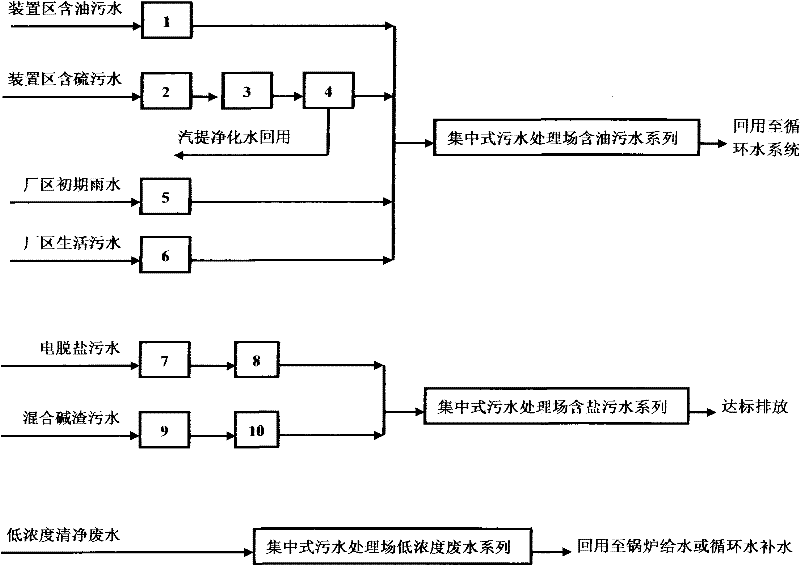

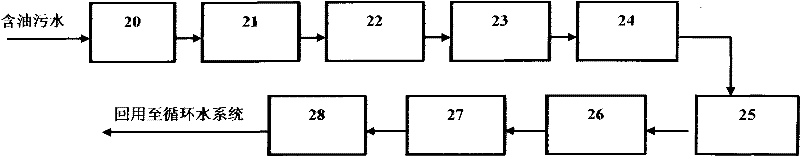

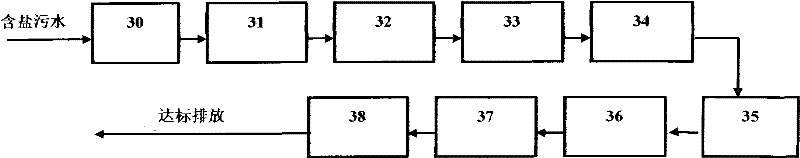

[0025] The specific implementation process of the method of the present invention will be described below in conjunction with the accompanying drawings.

[0026] The oil refinery wastewater classification control system and classification treatment method proposed by the present invention divide oil refinery wastewater into seven categories, including oily wastewater, sulfur-containing wastewater, electric desalination wastewater, mixed alkali residue wastewater, low-concentration clean wastewater, factory polluted rainwater, and domestic sewage. After degreasing in the device, the sewage is discharged into the centralized sewage treatment plant for oily sewage series treatment and then reused; after degreasing, the sulfur-containing sewage is sent to the acid water stripping device for pretreatment. After pretreatment, part of the effluent is reused, and the rest is discharged into the The oily sewage in the centralized sewage treatment plant is reused after series treatment; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com