Polyamide resin, polyamide resin composition, and molded article comprising same

A technology of polyamide resin and composition, which is applied in the field of polyamide resin, can solve the problems of high content, etc., and achieve the effects of low water absorption and excellent melt retention stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

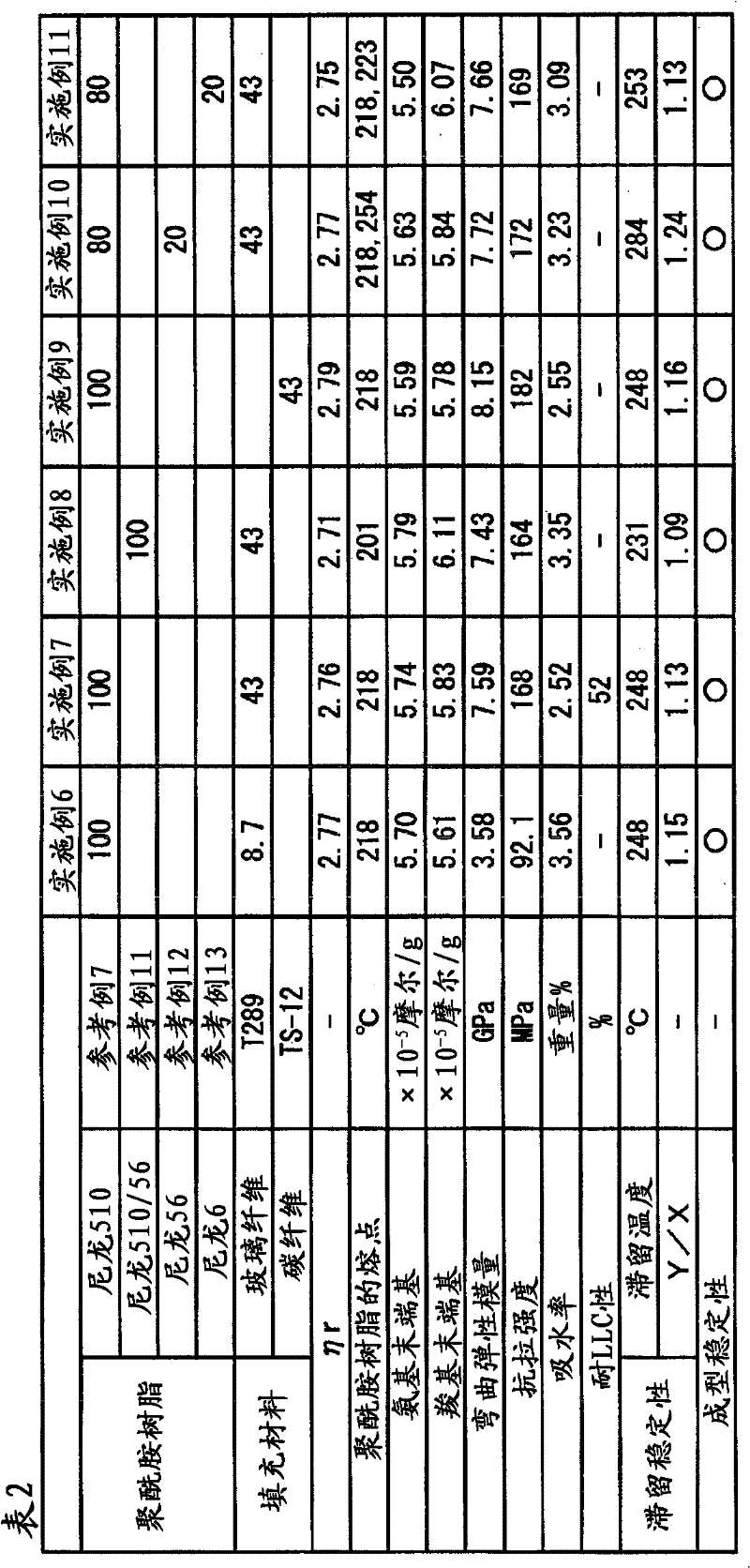

Examples

Embodiment

[0101] [Analysis of impurities contained in raw material 1,5-pentanediamine]

[0102] It carried out by the GC-MS method under the conditions shown below.

[0103] GC / MS: HP6980 / HP5973A

[0104] Column: NUKOL30m×0.24mmI.D.0.2μm film

[0105] Oven: 120°C (fixed)

[0106] InJ: 200°C (split ratio 10:1)

[0107] Flow rate: He2.4ml / min (constant flow)

[0108] MS: 230°C (scan m / z=30-400).

[0109] [Extraction of polyamide resin from polyamide resin composition compounded with fibrous filler]

[0110] 10 g of the polyamide resin composition was dissolved in 100 ml of hexafluoroisopropanol, and this was filtered to remove the fibrous filler. After evaporating the filtrate, it vacuum-dried at 80 degreeC for 12 hours, and obtained the polyamide resin extract.

[0111] [Relative viscosity (ηr)]

[0112] In 98% sulfuric acid, the measurement was performed using an Ostwald viscometer at a concentration of 0.01 g / ml at 25°C.

[0113] [Amino terminal group]

[0114] Accurately wei...

reference example 1

[0135] Reference example 1 (adjustment of lysine decarboxylase)

[0136] E. coli JM109 strain was cultured as follows. First, this strain was inoculated with 1 platinum loop in 5 ml of LB medium, and shaken at 30° C. for 24 hours to perform preculture. Next, 50 ml of the LB medium was added to a 500 ml Erlenmeyer flask, and steam sterilized at 115° C. for 10 minutes in advance. The above-mentioned strain after pre-culture was continuously inoculated in this medium, and culture was carried out for 24 hours while adjusting the pH value to 6.0 with 1N hydrochloric acid aqueous solution under conditions of an amplitude of 30 cm and 180 rpm. The bacterial cells thus obtained were collected, and subjected to ultrasonication and centrifugation to prepare a cell-free extract. The measurement of these lysine decarboxylase activities was carried out according to a conventional method (Kenji Satoda, Haruo Mizono, Biochemical Mitsuko Lecture, vol. 11, P. 179-191 (1976)). In the case of...

reference example 2

[0137] Reference example 2 (production of 1,5-pentanediamine)

[0138] With 0.1N hydrochloric acid aqueous solution, according to 50mM lysine hydrochloride (manufactured by Wako Pure Chemical Industries), 0.1mM pyridoxal phosphate (manufactured by Wako Pure Chemical Industries), 40mg / L-roughly purified lysine decarboxylase (from Reference Example 1 preparation) to maintain the pH value of 1000ml of the aqueous solution at 5.5 to 6.5, while reacting at 45°C for 48 hours to obtain 1,5-pentanediamine hydrochloride. By adding sodium hydroxide to this aqueous solution, 1,5-pentanediamine hydrochloride was converted into 1,5-pentanediamine, extracted with chloroform, and distilled under reduced pressure (10 mmHg, 60° C.), thereby obtaining 1, 5-pentanediamine. The 2,3,4,5-tetrahydropyridine contained in this pentamethylenediamine was 0.18% by weight, and the piperidine was 0.011% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com