Lift type comprehensive monitoring mechanism

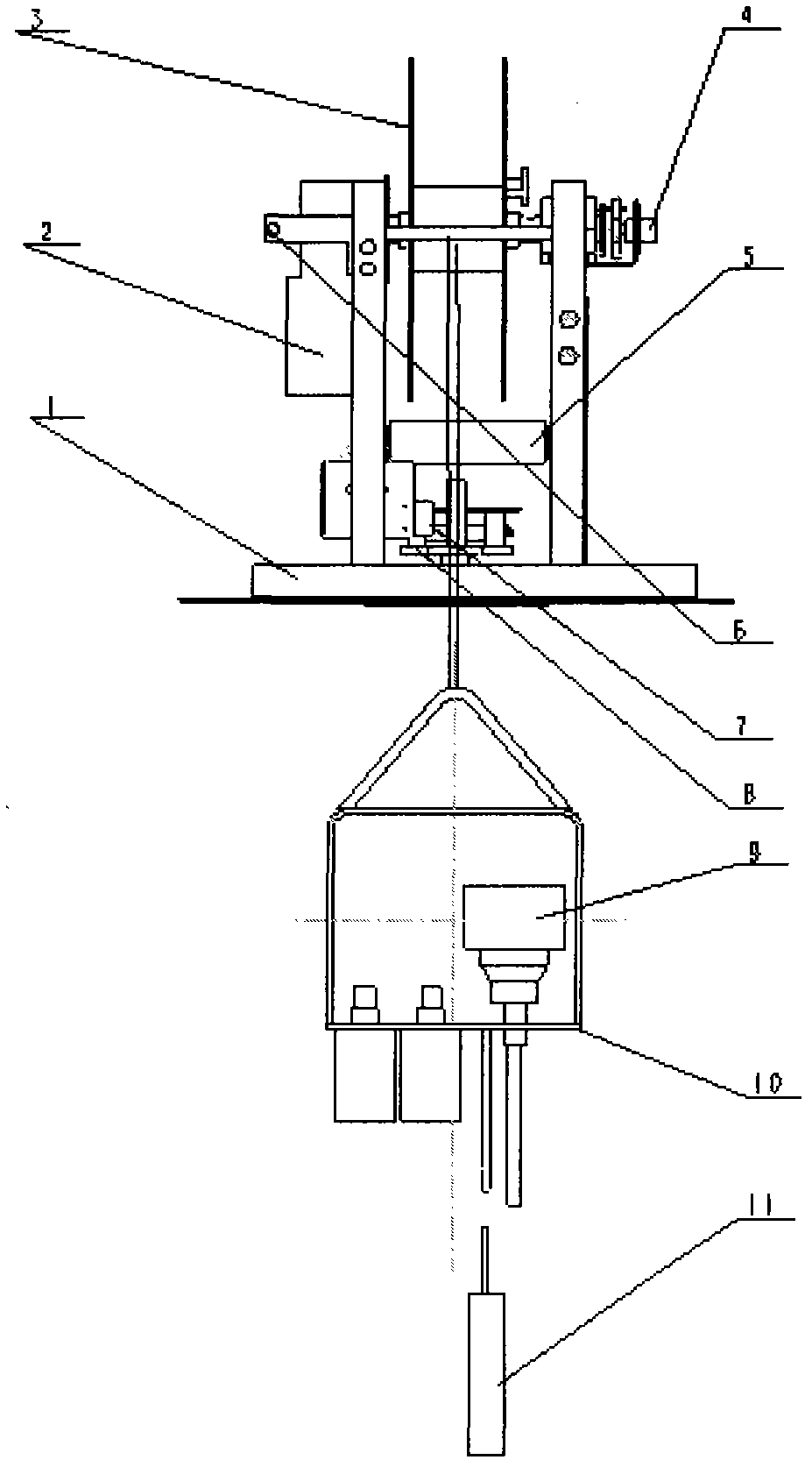

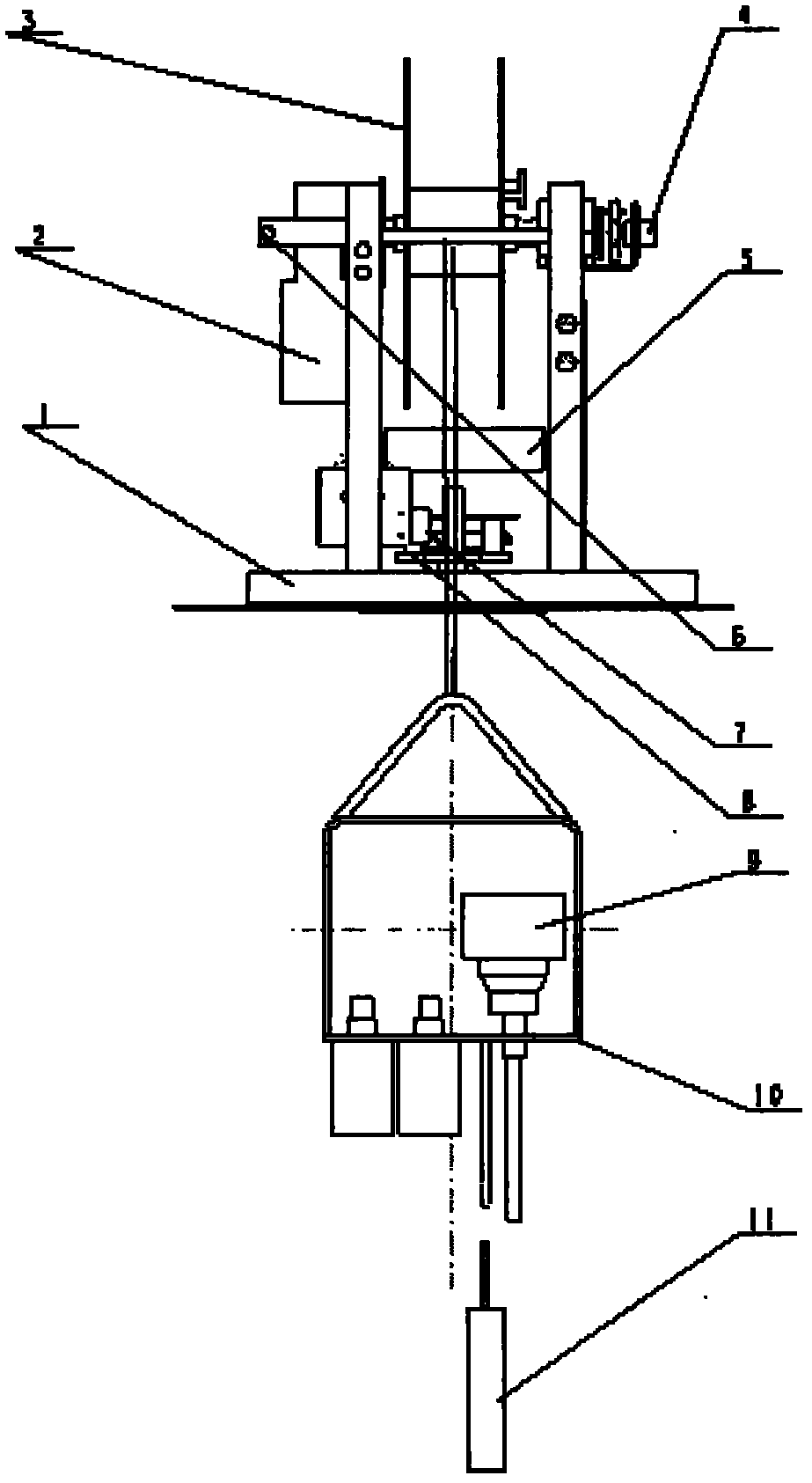

A comprehensive monitoring and lifting technology, which is applied in the direction of measuring devices and instruments, can solve the problems of reducing the number of control equipment, and achieve the effect of simple and practical structure, convenient maintenance and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The lifting comprehensive monitoring mechanism can be controlled locally by the control handle, or on a remote host computer; manual control is relatively simple, and the controller determines the forward and reverse rotation, operation and stop of the motor according to the observed situation; on the host computer, it is Connect with the single-chip communication module through the configuration software; the single-chip program controls the motor to run in the forward direction, and drives the roller to rotate forward to release the cable. The hanging basket moves downward, and the nylon roller can guide the cable; How many times the switch is turned on and off, that is, how many counting switch signals are generated, the height of the cable drop can be calculated; the height of the coal level can be converted by related formulas; when the tilt switch touches the surface of the material, a switch signal will be generated, and the motor will stop Rotate, the detection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com