Composite material pipe fitting joint

A composite material pipe and composite material technology, applied in the field of composite material pipe joints, can solve problems such as difficult processing and manufacturing, complicated process, and insufficient flexibility, and achieve the effects of simple and flexible implementation, good versatility, and simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

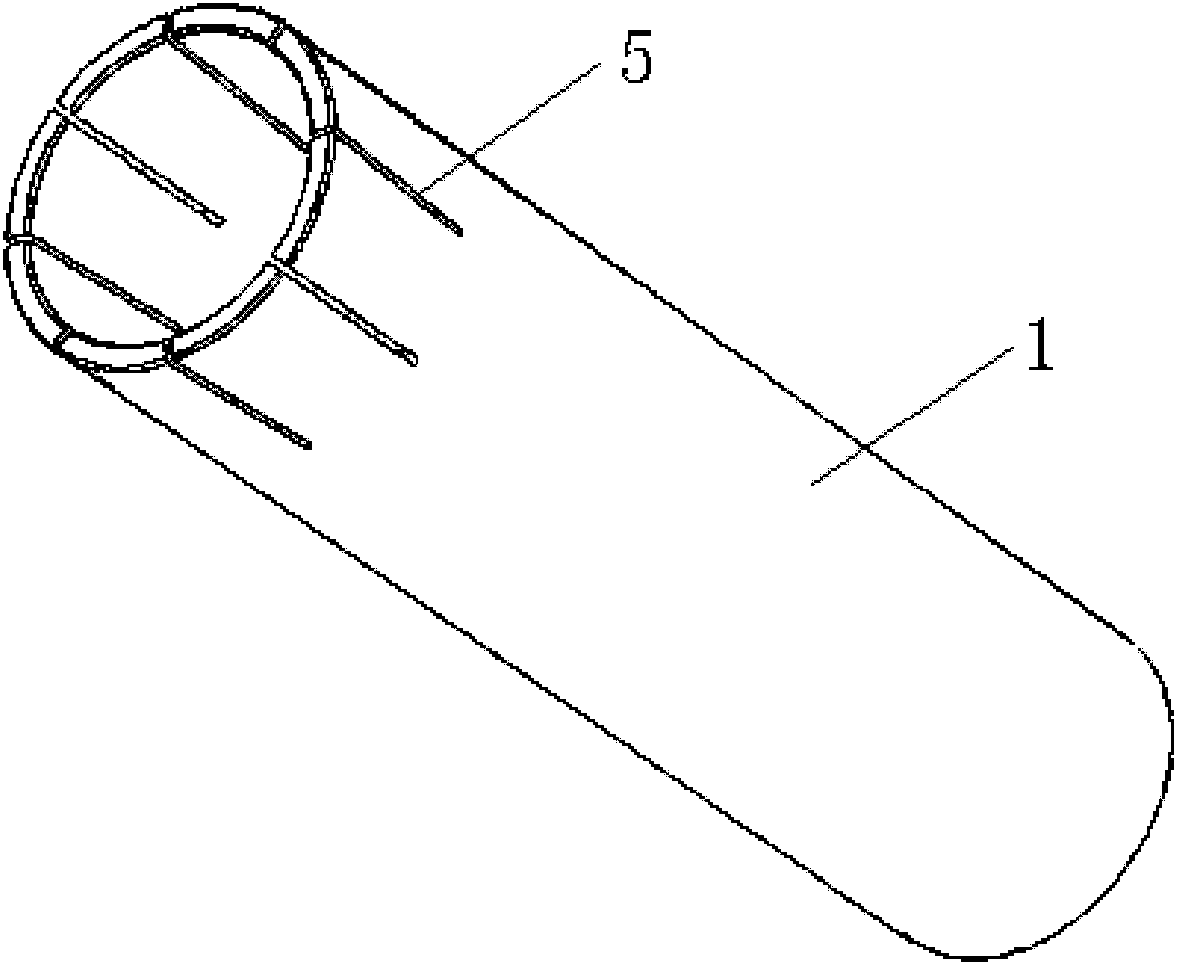

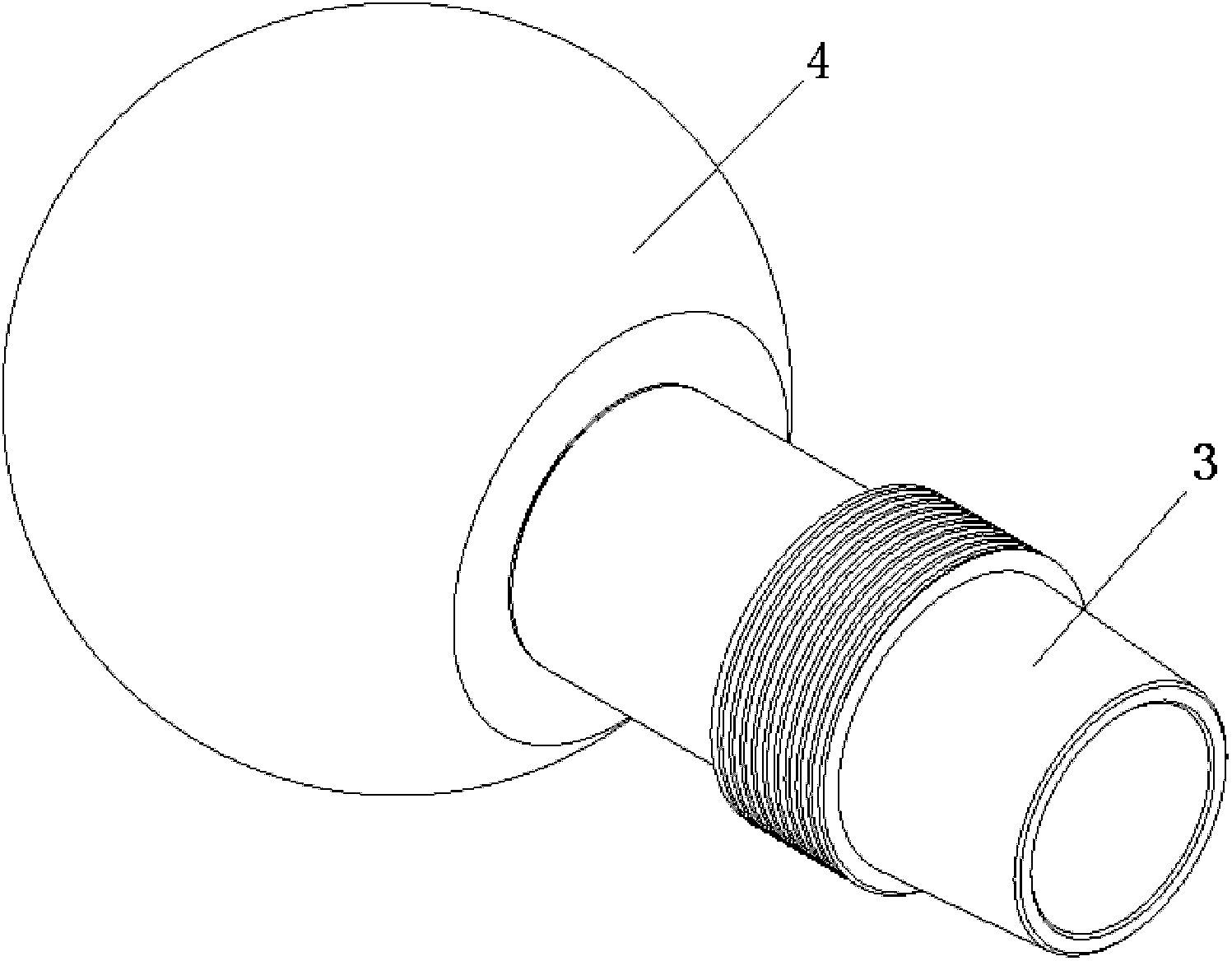

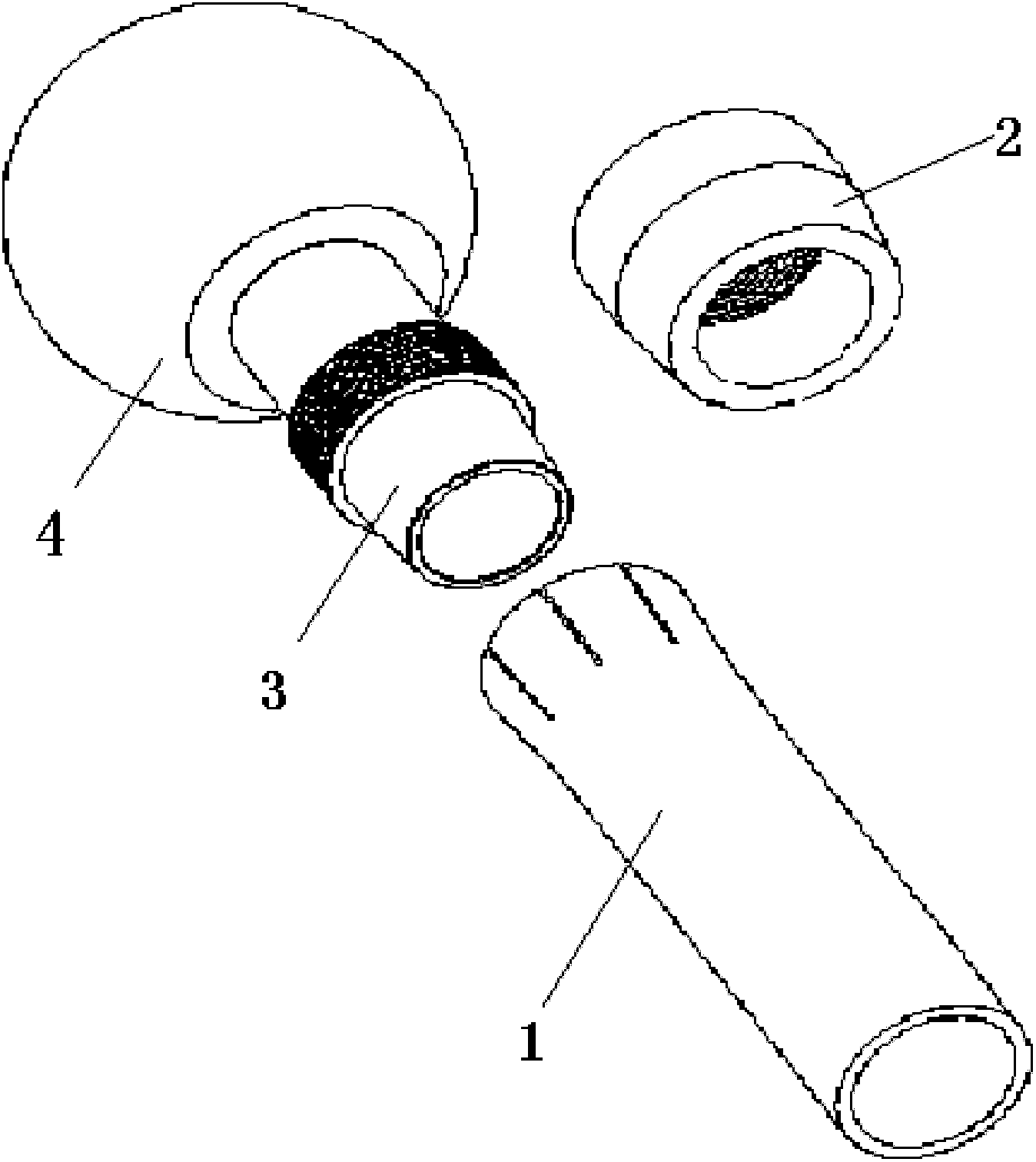

[0032] Embodiment 1, composite material pipe joint, refer to figure 1 , first process the required gap at one end of the composite tube; refer to Figure 5 : Put the composite material pipe 1 with the end processed into a seam into the end of the metal tightening cone pipe 2 without connecting threads; apply appropriate adhesive on the inner and outer pipe walls at the joint of the composite material pipe 1 and the middle of the sawed seam 5 ( Such as zero-expansion adhesive, etc.); insert the tapered part of the metal tapered tube 3 into the gapped end of the composite material tube 1, and use the taper of the metal tapered tube to open the nozzle of the composite material tube until the end surface of the nozzle is against the metal tapered tube 3 The side of the middle section; then evenly spread the adhesive in the composite material pipe 1 and its seam; then match the internal thread of the metal tightening taper sleeve 2 with the external thread of the middle section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com