Process and device for coating film on glass

A technology for coating film treatment and glass, which is applied in the field of technology and device for coating film on glass, and achieves the effects of facilitating production control, avoiding air bubbles and having good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

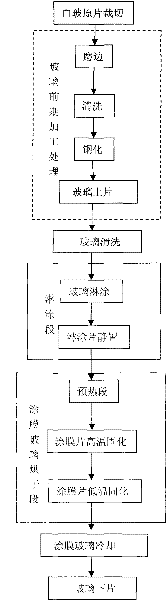

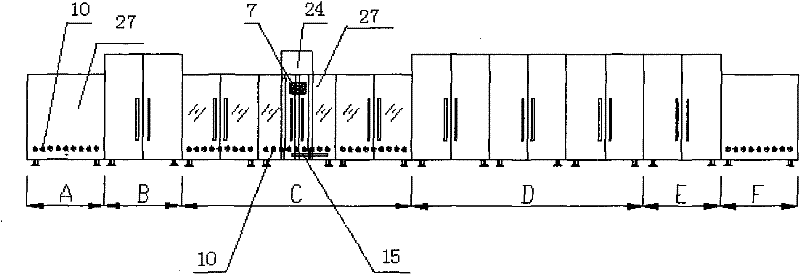

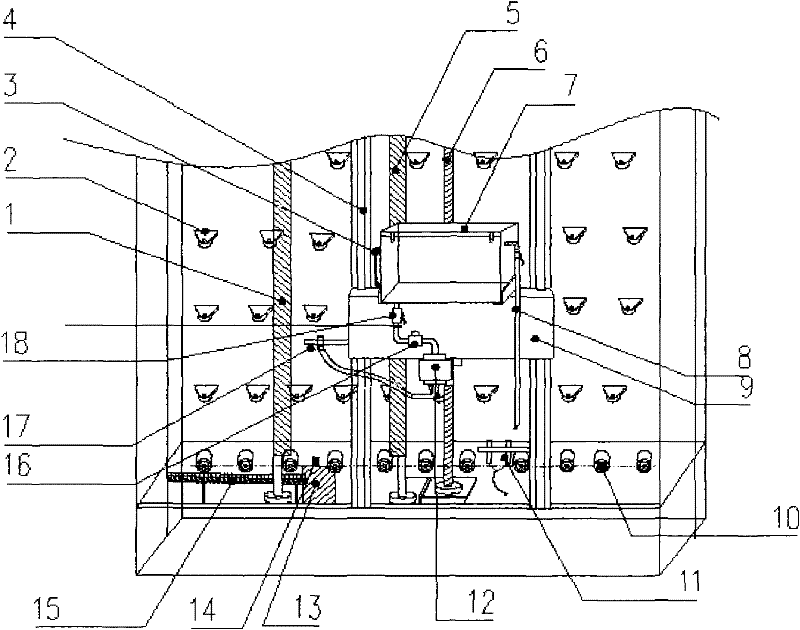

[0015] A kind of process and device for coating glass of the present invention will be described in detail below in conjunction with the accompanying drawings: The process steps of the glass coating process of the present invention are divided into glass pre-processing, glass sheeting, glass cleaning, shower coating, and shower coating. Standing the coated glass and drying the coated glass are divided into preheating, high temperature drying and curing, low temperature curing, coated glass cooling and glass unloading process (see figure 1 ); the overall structure schematic diagram of the device for glass coating treatment is as attached figure 2 As shown, except for the glass inlet and outlet, the rest of the device is closed and relatively isolated from the outside world; it consists of an upper section (A), a cleaning section (B), a coating section (C), a drying section (D), and a cooling section (E) and the lower segment (F) are partially composed, and a group of micro-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com