Cloth laying machine

A spreading machine and fabric technology, applied in the direction of spreading thin soft materials, thin material processing, transportation and packaging, etc., can solve problems such as warp and weft skew deviation, deviation, and defective products produced by cutting pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail in conjunction with the accompanying drawings and specific embodiments.

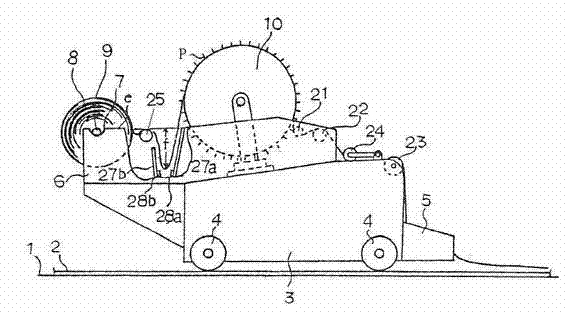

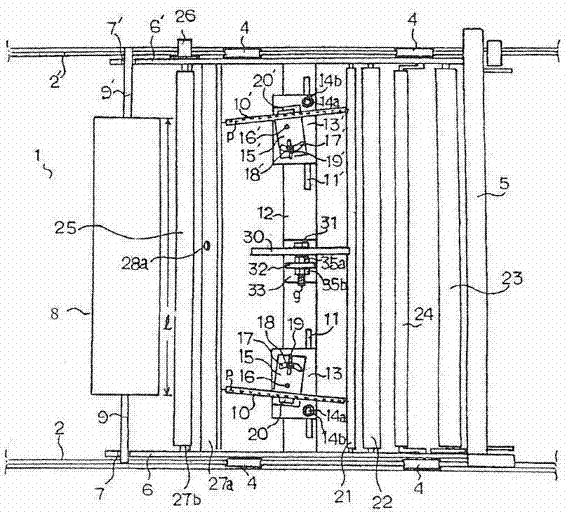

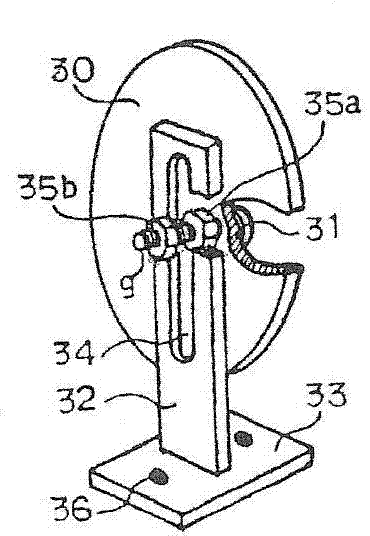

[0022] As shown in the figure, the present invention includes a platen 1, a track 2 arranged on both sides of the platen, a spreader body 3 traveling on the track 2, a driving mechanism 4, V-shaped guide plates 27a, 27b, and a fabric shaft. 9, 9', the guide device, the shearing device 5 arranged in front of the spreading machine body 3, the spreading machine body 3 is provided with a needle frame 12, and the needle frame 12 is provided with a needle plate 10, 10'. Loose cloth cylinder 25 is arranged in the middle of guide plate 27a, 27b and fabric shaft 9,9'; Support fabric drooping device is set below dial 10,10' middle fabric. The driving mechanism 4 includes a driving motor, a driving assembly for reciprocating travel within a set distance, wheels and the like.

[0023] At the back of the spreading machine body 3, there are bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com