Method for improving CMP (chemical mechanical polishing) process stability of polishing materials on polishing pad

A technology of grinding pads and abrasives, which is applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of wafer surface scratches, scrapping, and inability to detect in time, saving time and cost, simplifying the process, avoiding Damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

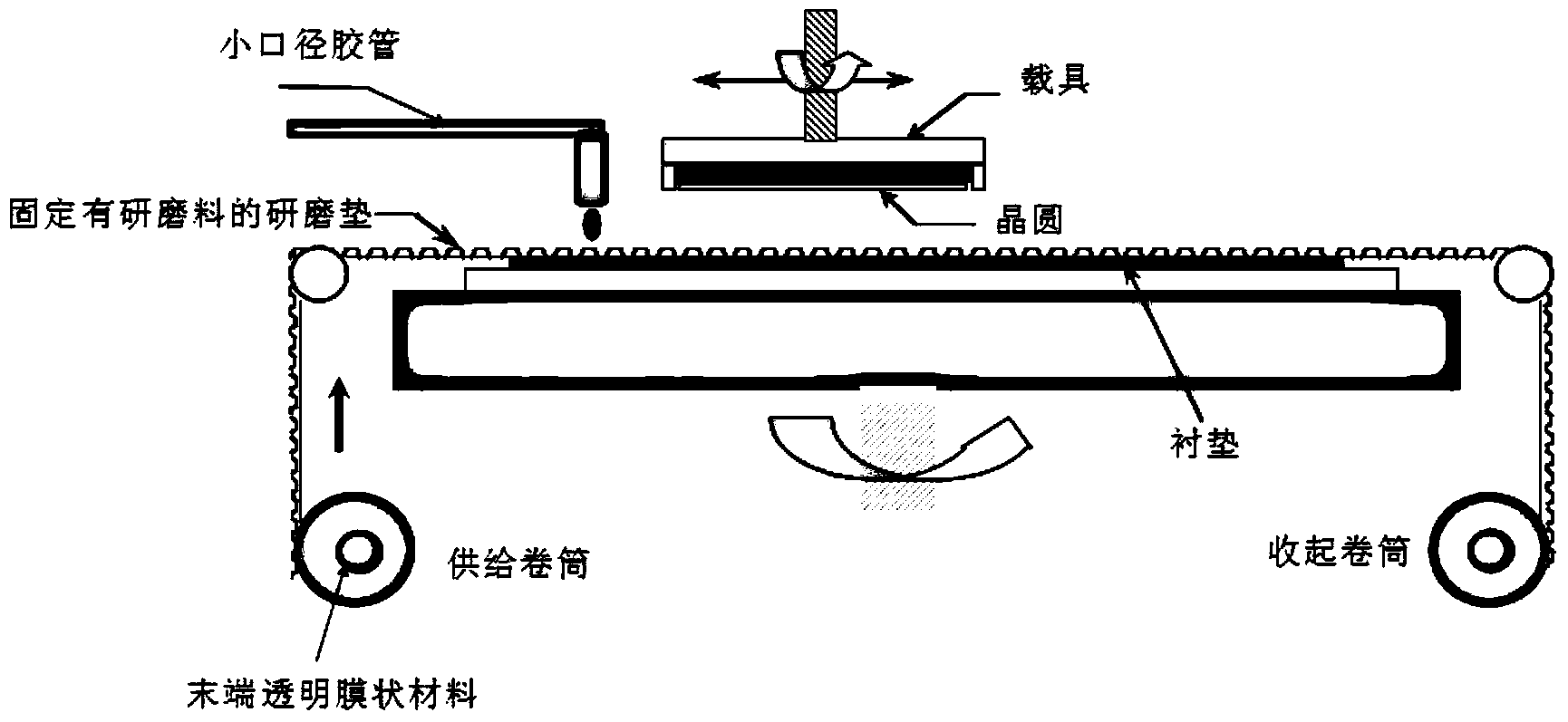

[0016] Figure 2-3 It is a structural schematic diagram of a method for improving the stability of a CMP process with fixed abrasives on a grinding pad in the present invention.

[0017] like Figure 2-3 As shown, a method of improving the stability of the CMP process of fixing the abrasive on the grinding pad of the present invention, on a CMP process machine, after the end of the grinding pad 1 with abrasive particles is fixed with air holes 5, the grinding The end of the pad 1 is wound on the supply roller of the machine through the transparent film 2 for the CMP process; wherein, the distance between the air holes 5 and the transparent film 2 is 10 cm.

[0018] During the CMP process, the polishing pad 1 steps along with the grinding wafer in the normal grinding state. When the part of the polishing pad 1 provided with the air vent 5 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com