Polishing fur with scratch preventing function

A function and scratch technology, which is applied in the field of polished leather with the function of avoiding scratches, can solve the problems of scratches on the polished surface and difficult control, and achieve the effect of avoiding serious scratches, ensuring polishing effect, and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

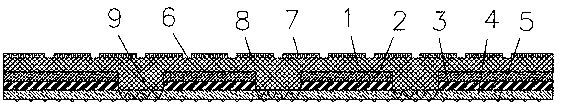

[0025] Example 1, such as Figure 1-3 Shown:

[0026] A kind of polished leather with the function of avoiding scratches, comprising a polyurethane layer 1, a back glue 2, a canvas 3, and a non-slip cloth 4; the outer surface of the polyurethane layer 1 is provided with a plurality of mutually vertical and interlaced square grooves 6, and the polyurethane layer The outer surface of 1 is separated by grooves 6 into a plurality of grid blocks 7 arranged in a rectangular array; each of the grid blocks 7 is provided with a plurality of micropores 8; the back of the polyurethane layer 1 is fixedly provided with A connecting column 9 with a cylindrical structure, the back of the polyurethane layer 1 is fixedly bonded with a layer of adhesive 2; the other side of the adhesive 2 is fixedly bonded with a layer of canvas 3, and the outer surface of the canvas 3 is fixedly sewn There is a layer of anti-skid cloth 4; the position corresponding to the connecting column 9 on the adhesive b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com