Self-fastening type ball mill cylinder

A ball mill and self-fastening technology, applied in the field of ball mill barrels, can solve problems such as bolt breakage, and achieve the effects of increasing tightness, eliminating the phenomenon of pulverized coal leakage, and ensuring safe and economical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention, all equivalent technical solutions also belong to the category of the present invention, and the patent protection scope of the present invention should be defined by each claim.

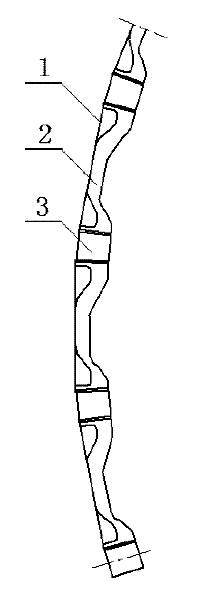

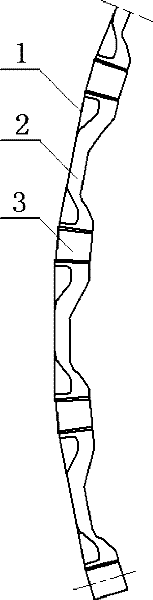

[0012] from figure 1 It can be seen from the figure that a self-fastening ball mill cylinder includes a cylinder body 1, several liners 2 and wedging blocks 3, and is characterized in that: the several liners 2 and wedging blocks 3 are in pairs The phases are fixed on the cylinder body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com