Direct current motor servo driver

A technology of servo drive and DC motor, which is applied in the direction of controlling multiple DC motors, can solve the problems of increasing the size and power consumption of the control system, increasing the difficulty of system development, and complicated wiring of the control box, so as to improve the anti-interference ability and reduce the system cost. Effects of size and power consumption, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The invention provides a DC motor servo driver. As a specific implementation mode, the present invention will be described below with reference to the control and drive of a brushed DC motor with a rated voltage of 24V.

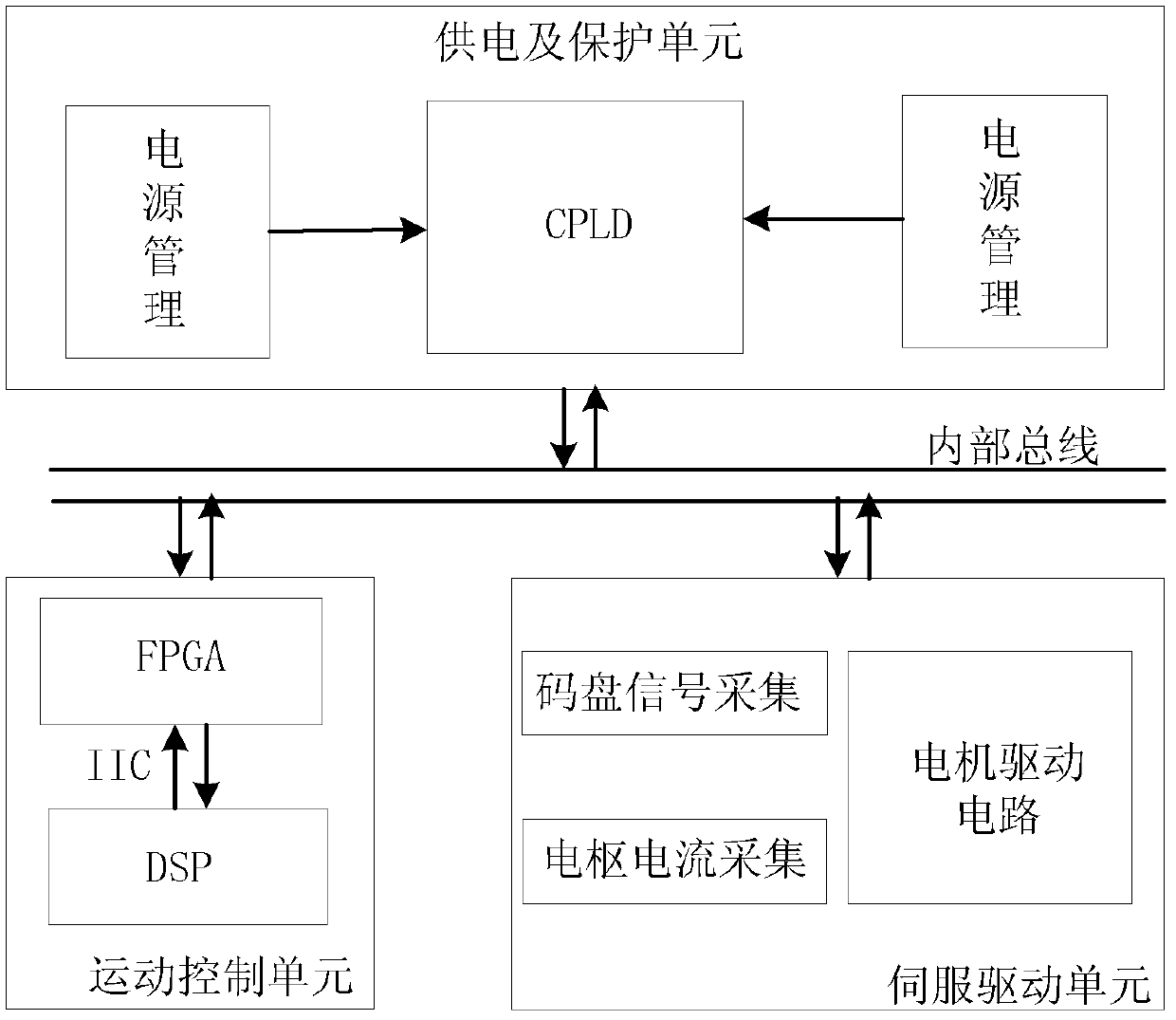

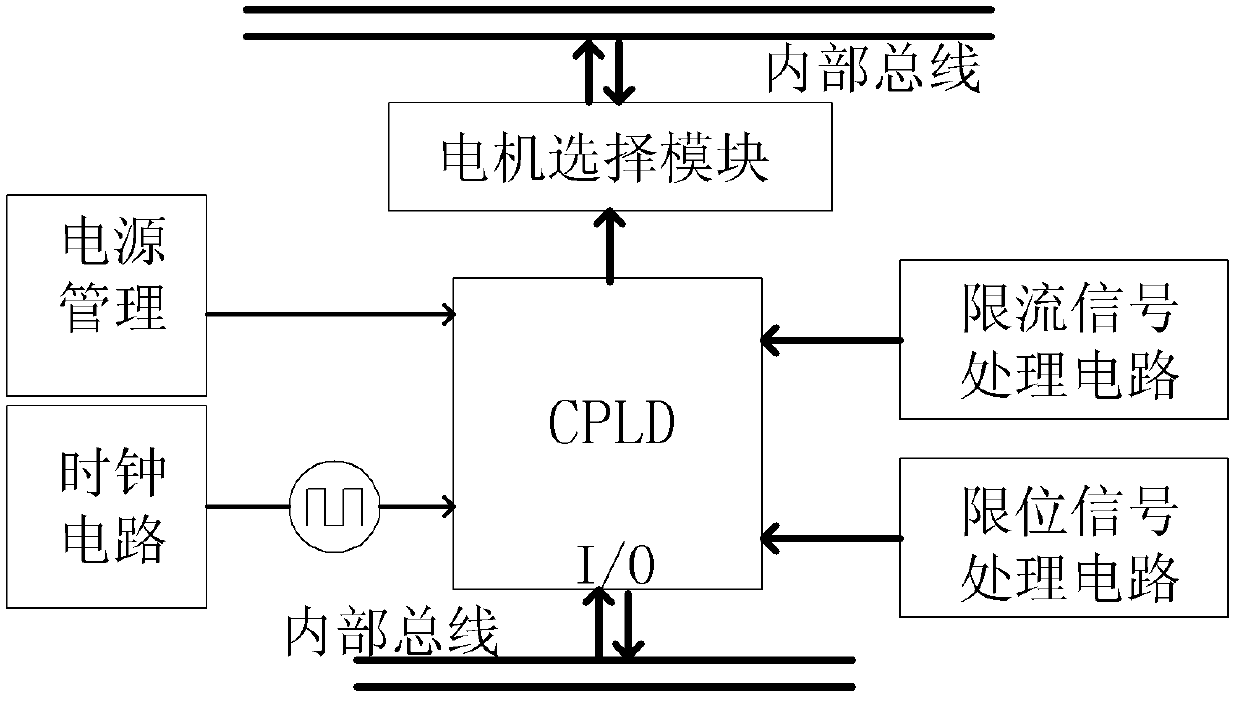

[0029] According to this embodiment of the present invention, the DC motor servo drive is composed of a motion control unit, a power supply and protection unit, and a servo drive unit.

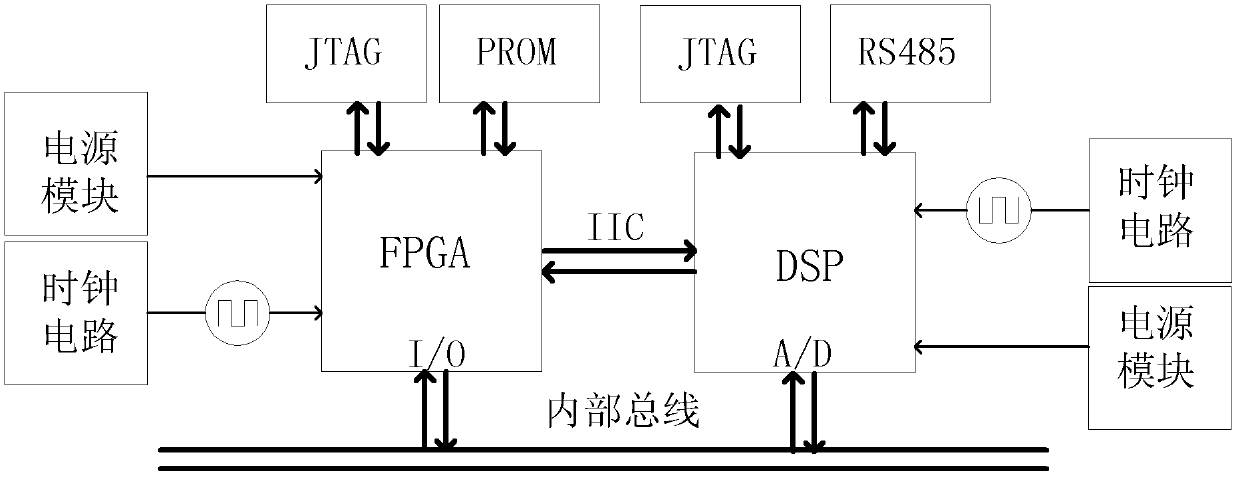

[0030] Among them, the motion control unit is mainly composed of a digital signal processor (DSP) and its configuration circuit, a programmable logic device (FPGA) chip and its configuration circuit, an internal bus and peripheral circuits, and is used to plan the movement of the motor.

[0031] The motion planning is mainly to carry out internal trajectory planning and interpolation calculation, and read the motor code disc operating parameters in the FPGA through the internal bus to obtain the difference between the expected position of the desired motor and the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com