Low grid-drain capacitance grooved metal oxide silicon (MOS) device and manufacturing method thereof

A technology of MOS devices and leakage capacitors, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problem of poor Cgd/Cgs consistency, affecting device performance and device reliability, and affecting the ability of devices to suppress false turn-on and other issues, to achieve the effect of suppressing false turn-on ability, improving device performance and reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

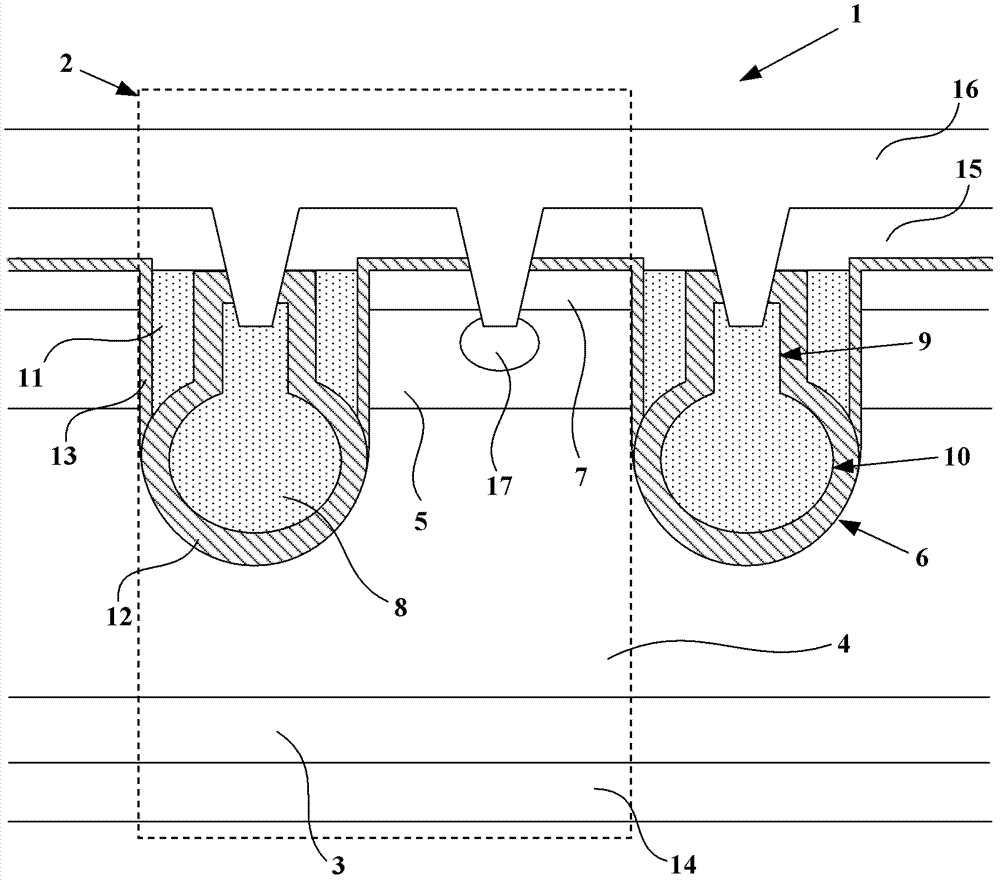

[0056] Embodiment: a trench MOS device with low gate-to-drain capacitance, the active region 1 of the device is composed of several trench MOS unit cells 2 arranged in parallel; on the lateral section of the active region 1, each trench The MOS unit cell 2 includes a heavily doped drain region 3 of the first conductivity type located on the back side of the silicon wafer, an epitaxial layer 4 of the first conductivity type lightly doped above the drain region 3; The well layer 5 of the second conductivity type in the inner upper part; the trench 6 passing through the well layer 5 and extending to the epitaxial layer 4; the first conductive type in the upper part of the well layer 5 and located around the trench 6 type heavily doped first source region 7;

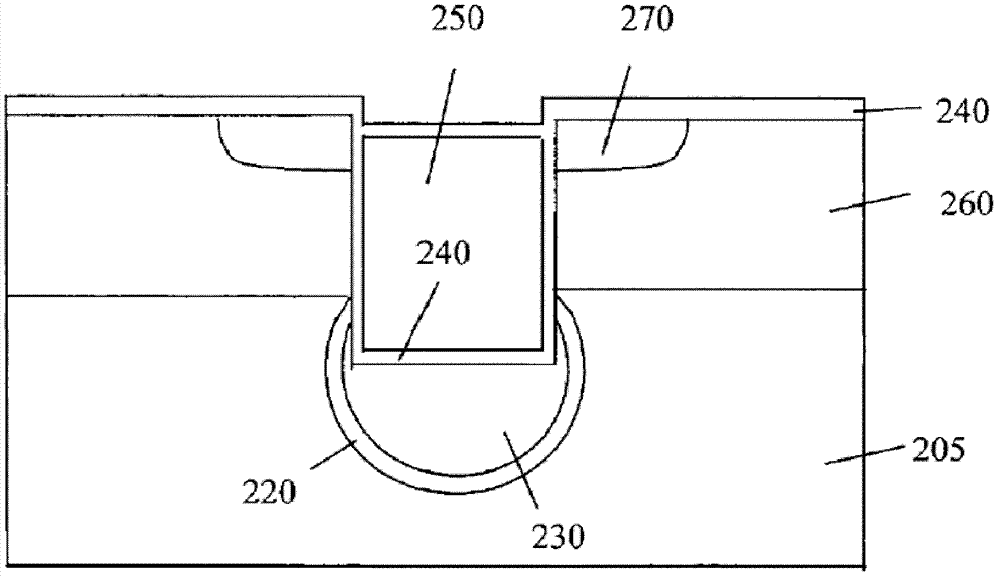

[0057] The bottom of the groove 6 is semi-circular arc-shaped, and the diameter of this semi-circular arc is not smaller than the opening size of the groove 6. The second electrode region is located in the center of the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com