Blue-light-excited TFT (thin film transistor)-LED (light emitting diode) array display substrate and manufacturing method thereof

A technology of TFT-LED and array display substrate, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of high production cost, poor color uniformity, and low resolution, and achieve easy large-scale industrialization , improve heat dissipation, and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

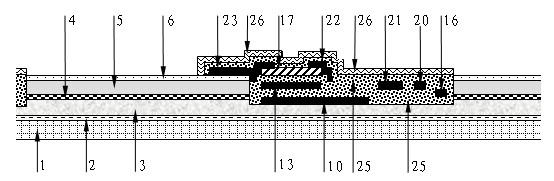

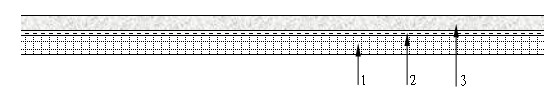

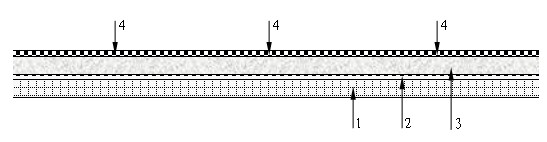

[0082] A blue light excitation TFT-LED array display substrate structure of the present invention is as follows Figure 24As shown, above the substrate 1 are the buffer layer 2 and the n-type GaN layer 3 in sequence; on the n-type GaN layer 3 is the blue light emitting layer 4, and on the blue light emitting layer are the p-type GaN layer 5 and the transparent electrode in sequence Layer 6. The n-type GaN layer 3, the blue light-emitting layer 4, the p-type GaN layer 5 and the transparent electrode layer 6 together form a display unit. A control area 7 is provided on the display unit, and a lead area 8 is provided between the display units. In the control area 7, there is a capacitor composed of the lower plate 10 of the capacitor, the upper plate 12 of the capacitor, and the insulating layer 25 between the upper and lower plates. A working TFT composed of a working TFT gate 13, a working TFT channel 17, a working TFT source 22, a working TFT drain 23 and an intermediate insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com