Optical axis levelling and gravity unloading supporting method of large diameter lightweight mirror

A lightweight mirror, gravity unloading technology, applied in the field of optics, to achieve the effect of stable support state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

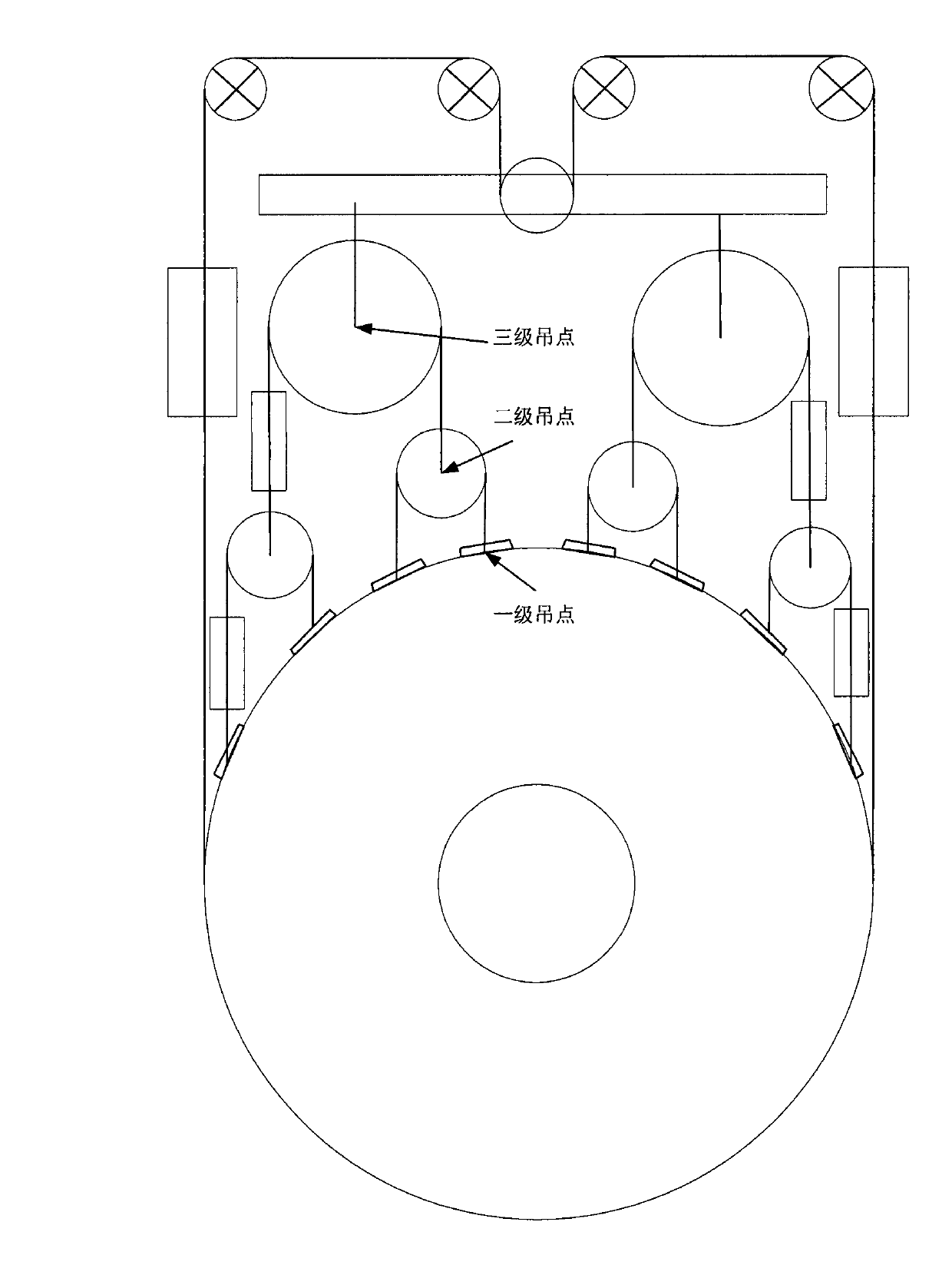

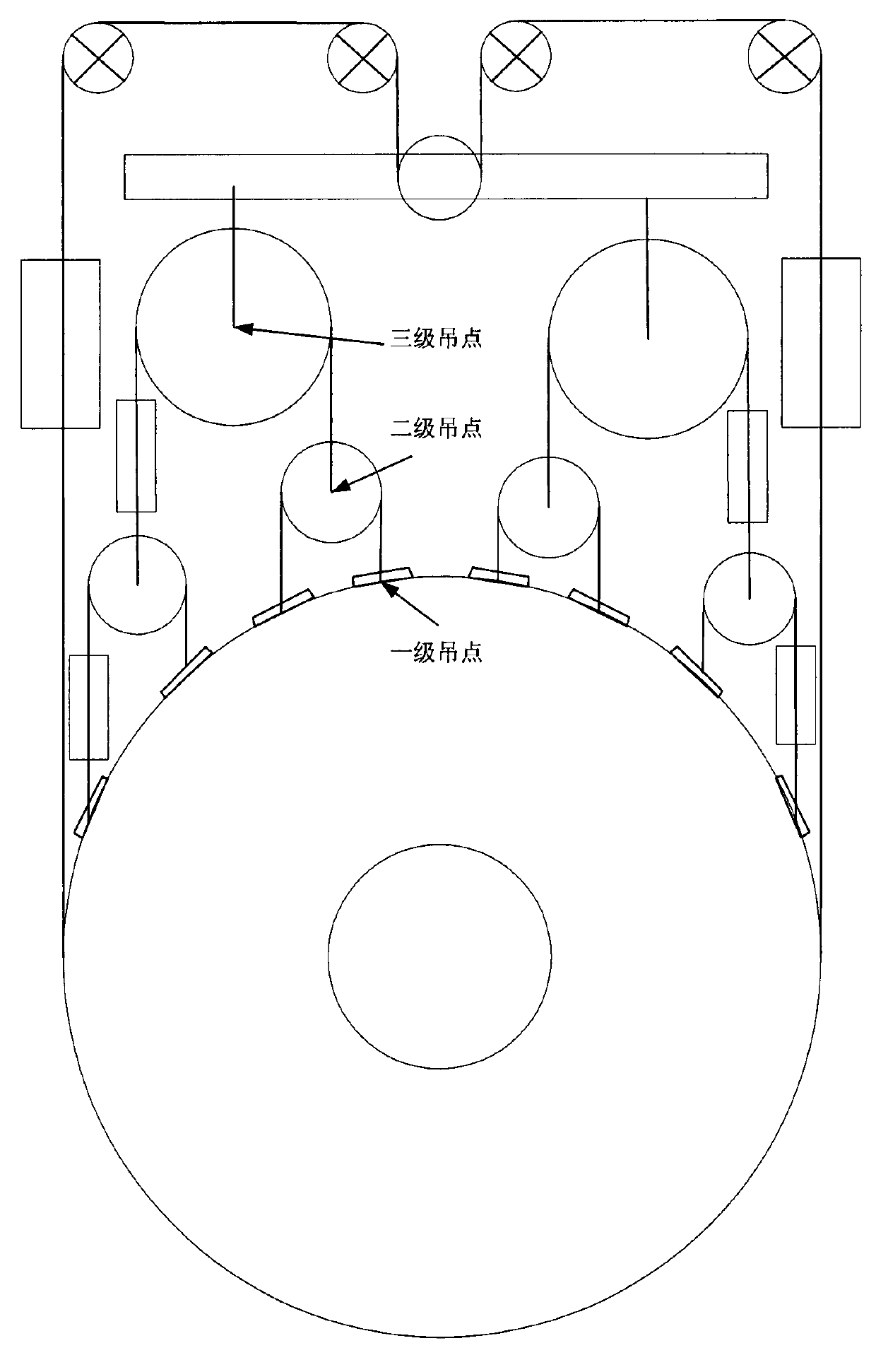

[0021] Such as figure 1 Shown is the schematic diagram of the method of the present invention, and the frocks involved in the method of the present invention include slings, large-caliber light mirrors, suspension points, wire ropes, counterweights, movable pulleys, lever beams, fixed pulleys, etc.

[0022] The main steps are as follows:

[0023] (1) Fix the first fixed pulley, the second fixed pulley, the third fixed pulley and the fourth fixed pulley sequentially from left to right in the horizontal direction, and arrange the first movable pulley below the second fixed pulley and the third fixed pulley; The distance between the outer tangent of a certain pulley and the outer tangent of the fourth fixed pulley is equal to the diameter of the disc reflector, and the first movable pulley is located on the perpendicular bisector of the center line of the second fixed pulley and the third fixed pulley, The first moving pulley is fixed in the middle of the lever beam;

[0024] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com