Detecting method for identifying dynamic mechanical property parameters of materials in different zones of welding spot

A technology of dynamic mechanics and detection methods, applied in the direction of testing the hardness of materials, etc., can solve the problems of difficulty in determining the initial cross-sectional area A0 of each area to be measured, and the inability to directly fit dynamic mechanical performance parameters, so as to broaden the scope of use and strengthen engineering. Use value, high practical value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

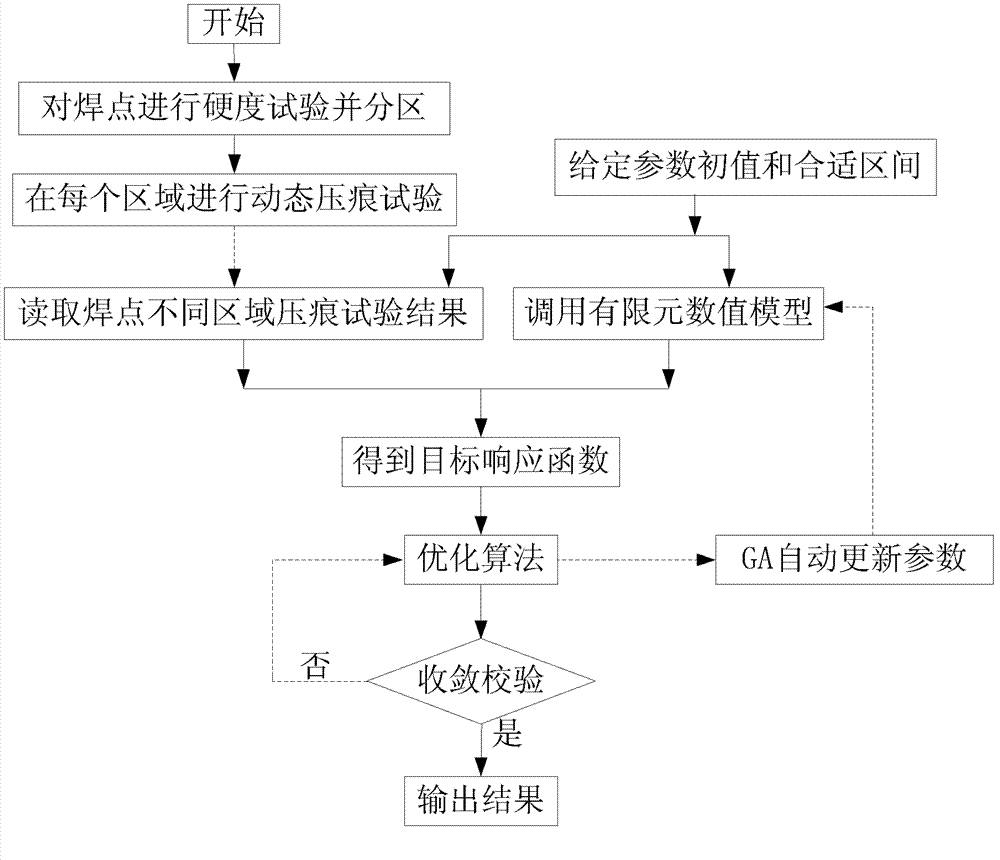

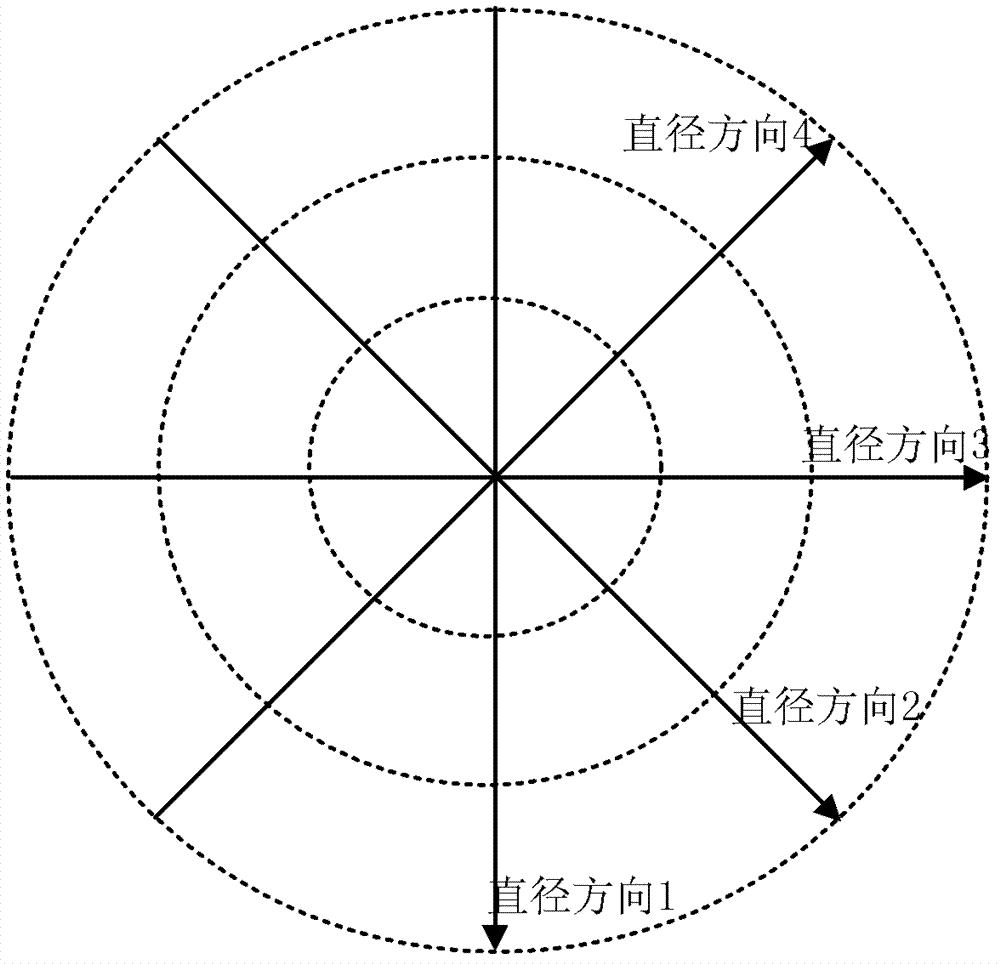

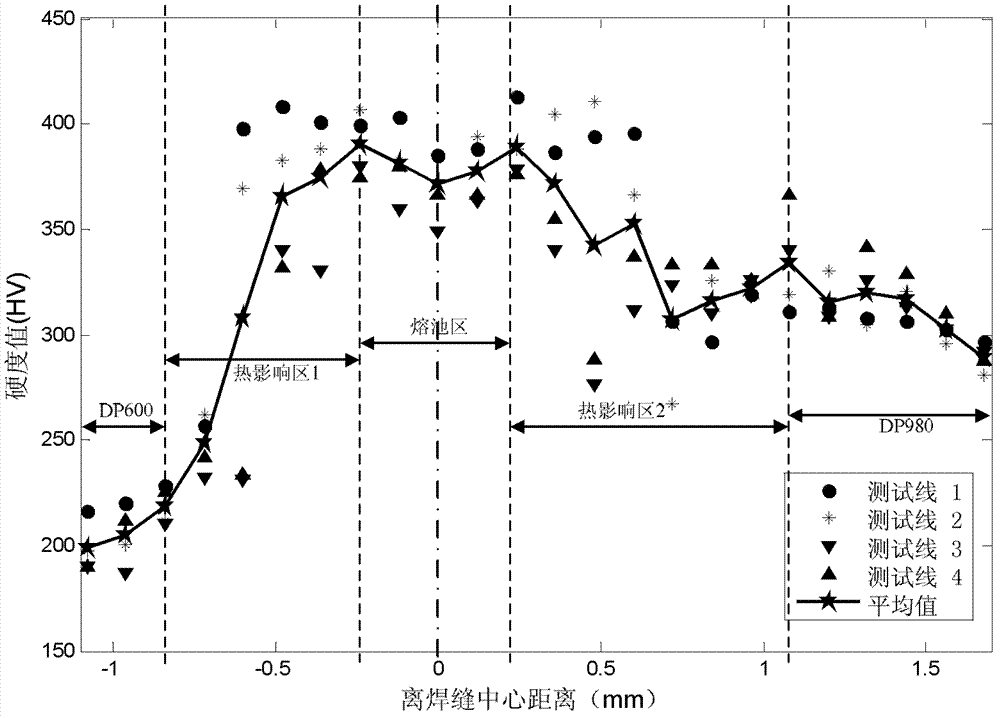

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Because the deformation of most engineering polycrystalline metal materials under the action of impact load is often simulated by using the most extensive Johnson Cook strengthening model, so the present invention adopts this model as the constitutive relation of this embodiment, as shown in formula (1), It can be seen from the formula that the J-C model is expressed as the product of three terms, which respectively reflect strain hardening, strain rate hardening and temperature softening (note: the modified form of the J-C model is used here).

[0031] σ = ( A + B ϵ n ) [ 1 + CIn ( 1 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com