Spectral surface resetting device of hyperspectral imager

An imager and hyperspectral technology, which is applied in the field of hyperspectral imager spectrum adjustment device, can solve the problems of complicated adjustment process and inability to accurately measure the image plane position of hyperspectral imaging instrument, so as to facilitate the adjustment process and avoid blindness The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

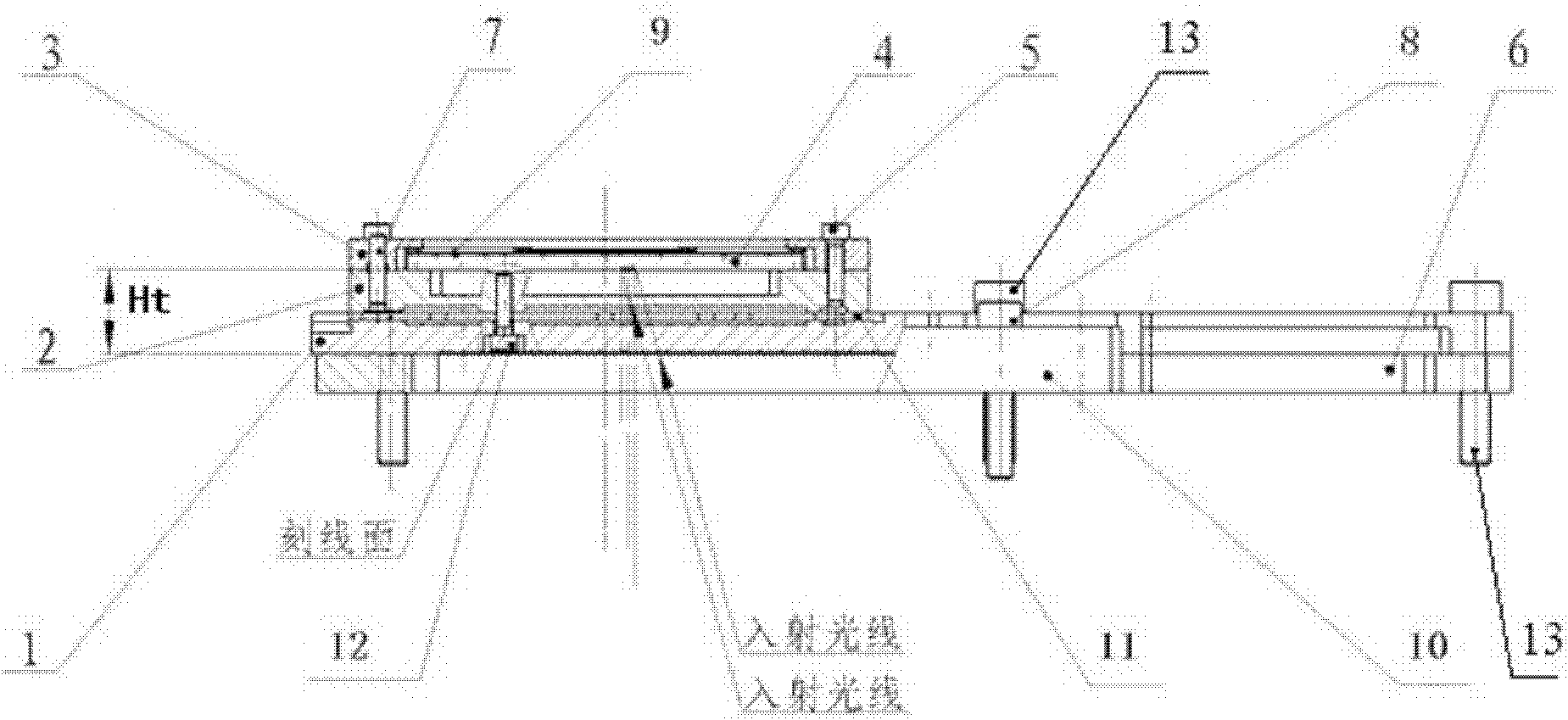

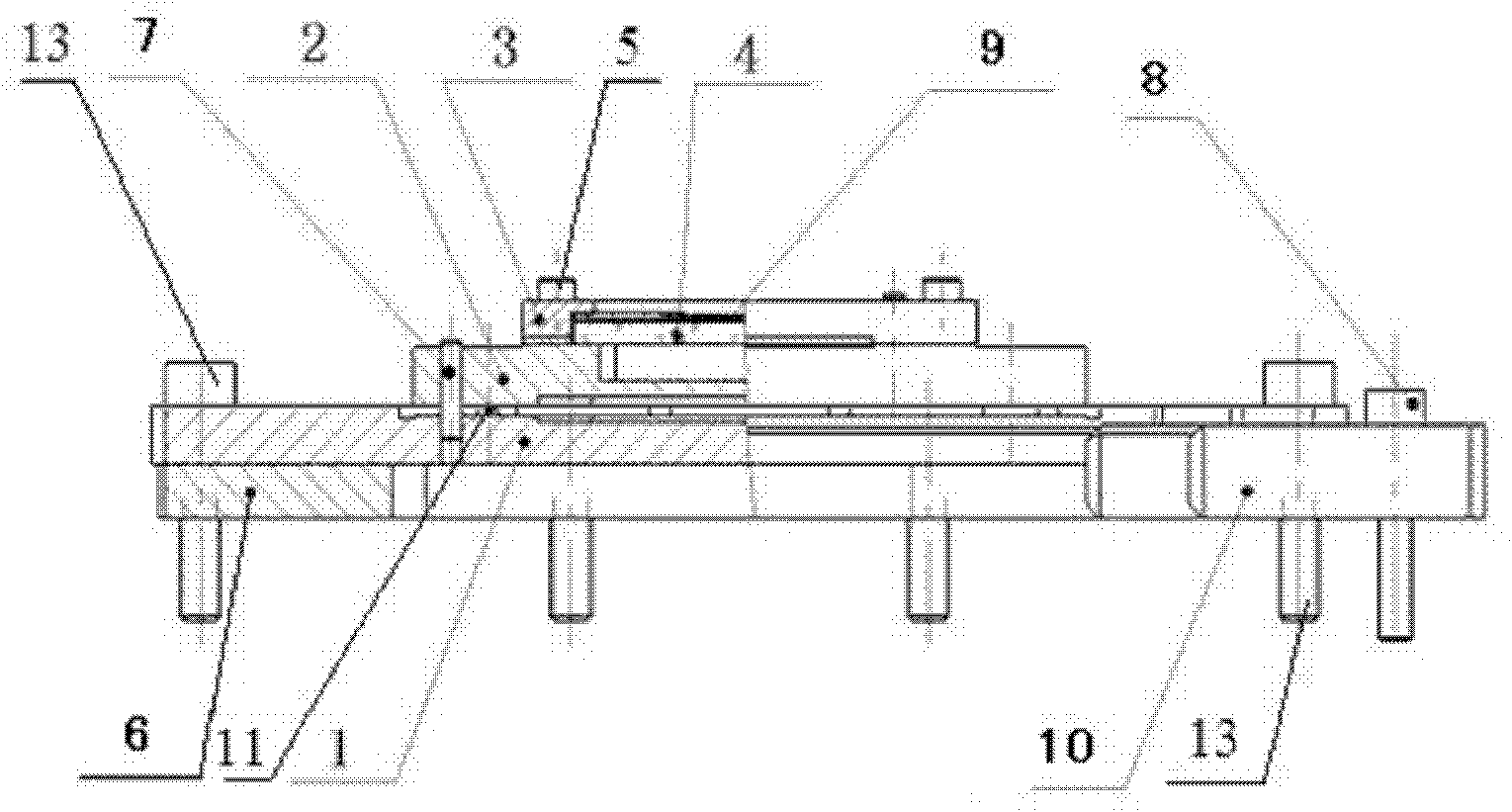

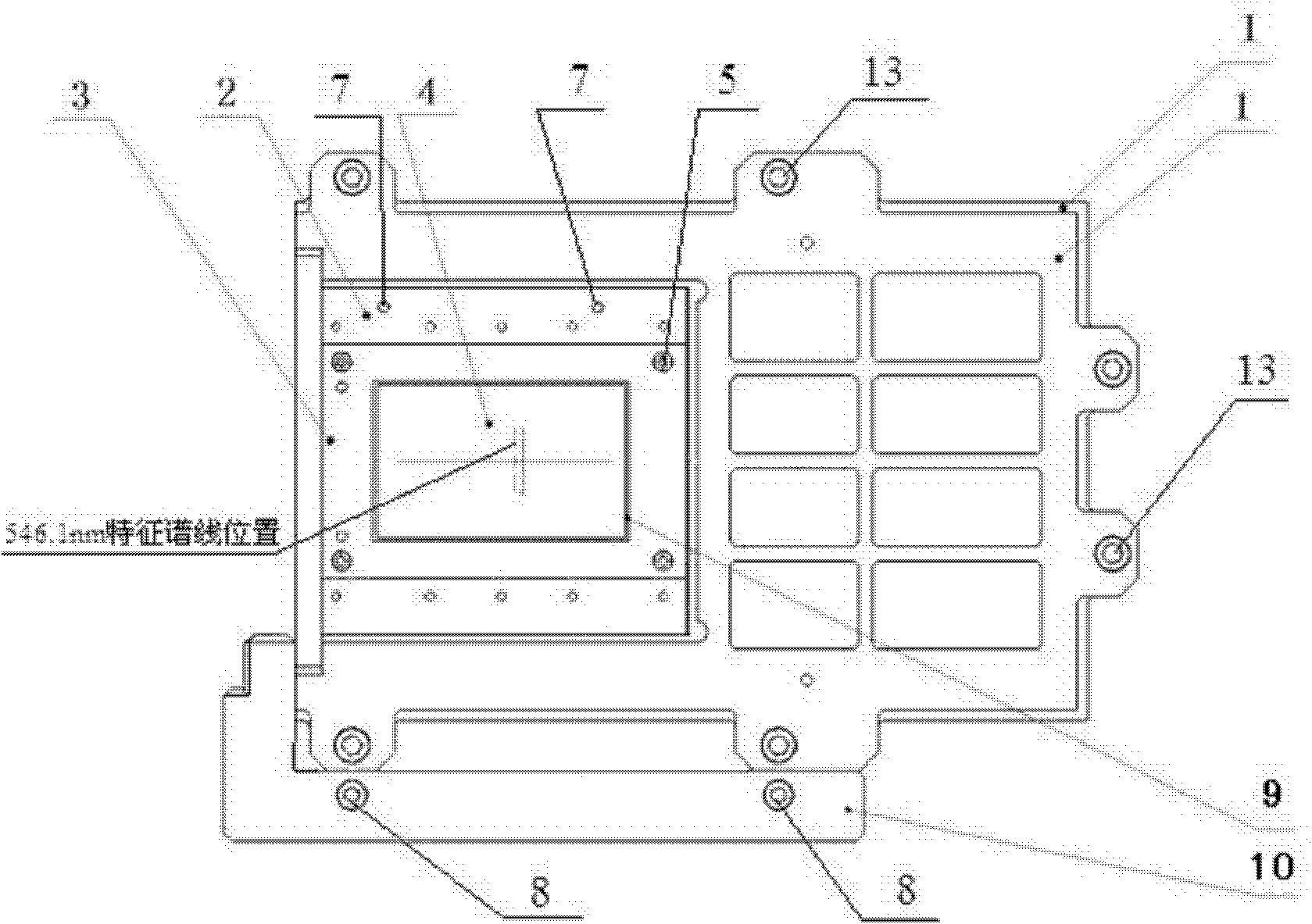

[0014] Specific implementation mode 1. Combination Figure 1 to Figure 6 Describe this embodiment, the hyperspectral imager spectrum surface installation and adjustment device, the device includes a substrate 1, a reticle assembly and a positioning pin 7, and the reticle assembly includes a reticle seat 2, a positioning frame 3, a reticle 4. Positioning frame screw 5, reticle elastic pressure plate 9, reticle seat adjustment pad 11 and reticle seat fixing screw 12, reticle seat adjustment pad 11 is set between the substrate 1 and reticle seat 2 , the substrate 1 and the reticle base 2 are positioned by positioning pins 7; the reticle base 2 and the positioning frame 3 are fixed by the positioning frame screws 5, and the reticle elastic pressure plate 9 and the positioning frame 3 are sequentially arranged Reticle 4 ; the reticle assembly is fixed to the substrate 1 by reticle fixing screws 12 .

specific Embodiment approach 2

[0015] Specific embodiment two, combine Image 6 Describe this implementation mode, this implementation mode is the application of the hyperspectral imager spectral surface installation and adjustment device described in the first specific embodiment in the installation and adjustment process:

[0016] First of all, according to the position and distance from the reference installation surface of the CCD focal plane assembly 14 to the image plane, the installation and adjustment device according to the present invention is passed through the grinding of the reticle seat adjustment pad 11 between the reticle seat 2 and the substrate 1. The adjustment of the distance from the adjustment device to the image plane is completed on the contact surface, and the corresponding adjustment is made along the meridional direction and the sagittal direction of the image plane, so that the 546.1nm spectral line of the hyperspectral imager should be aligned with the CCD inside the CCD focal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com