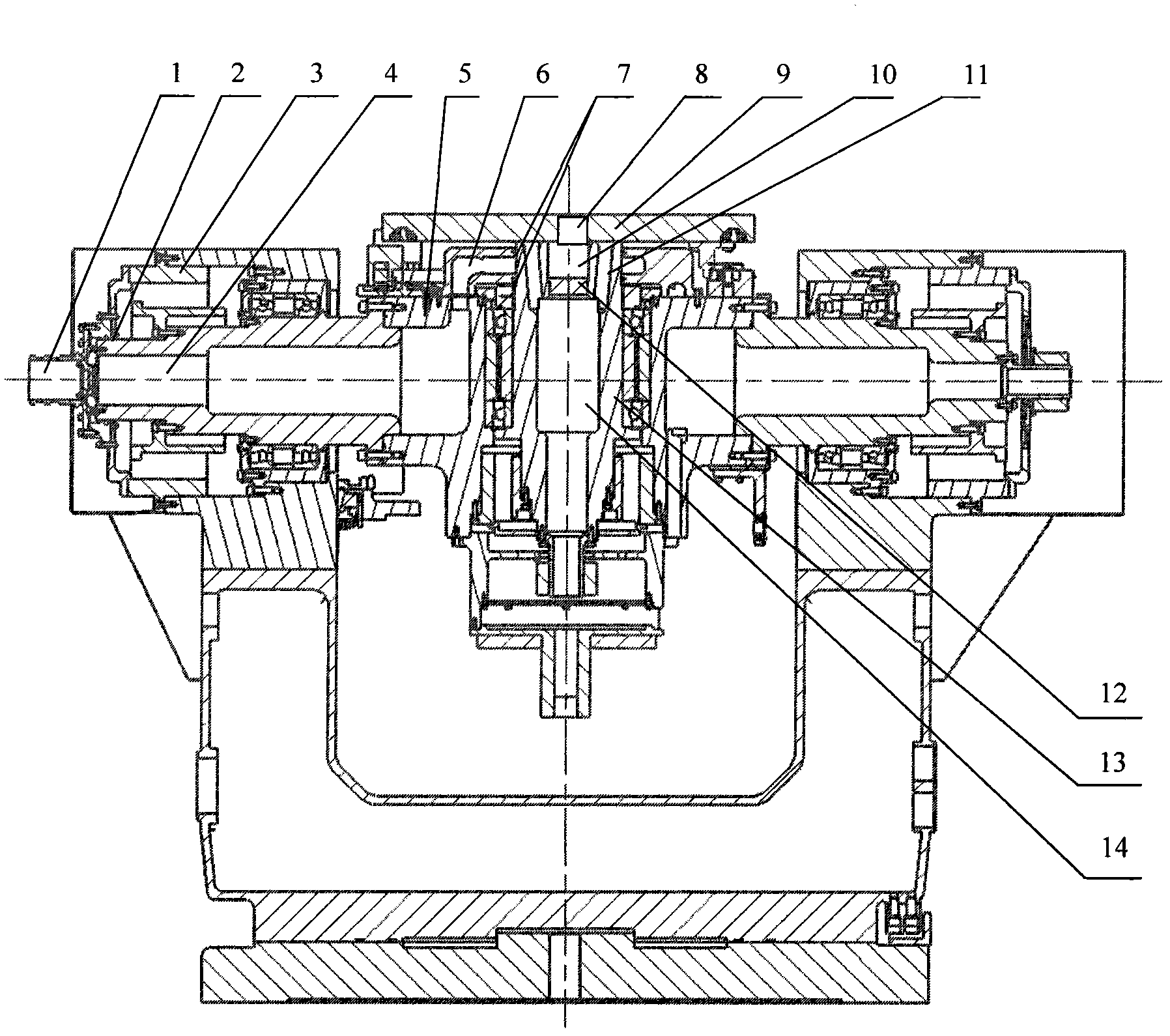

Two-shaft automatic turntable structure with built-in air ducts

An automatic turntable and air duct technology, applied in the field of measurement, can solve the problems of limiting the angular movement range, damaging the DUT and the turntable, failing to meet the test requirements, etc., and achieving the effect of solving winding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

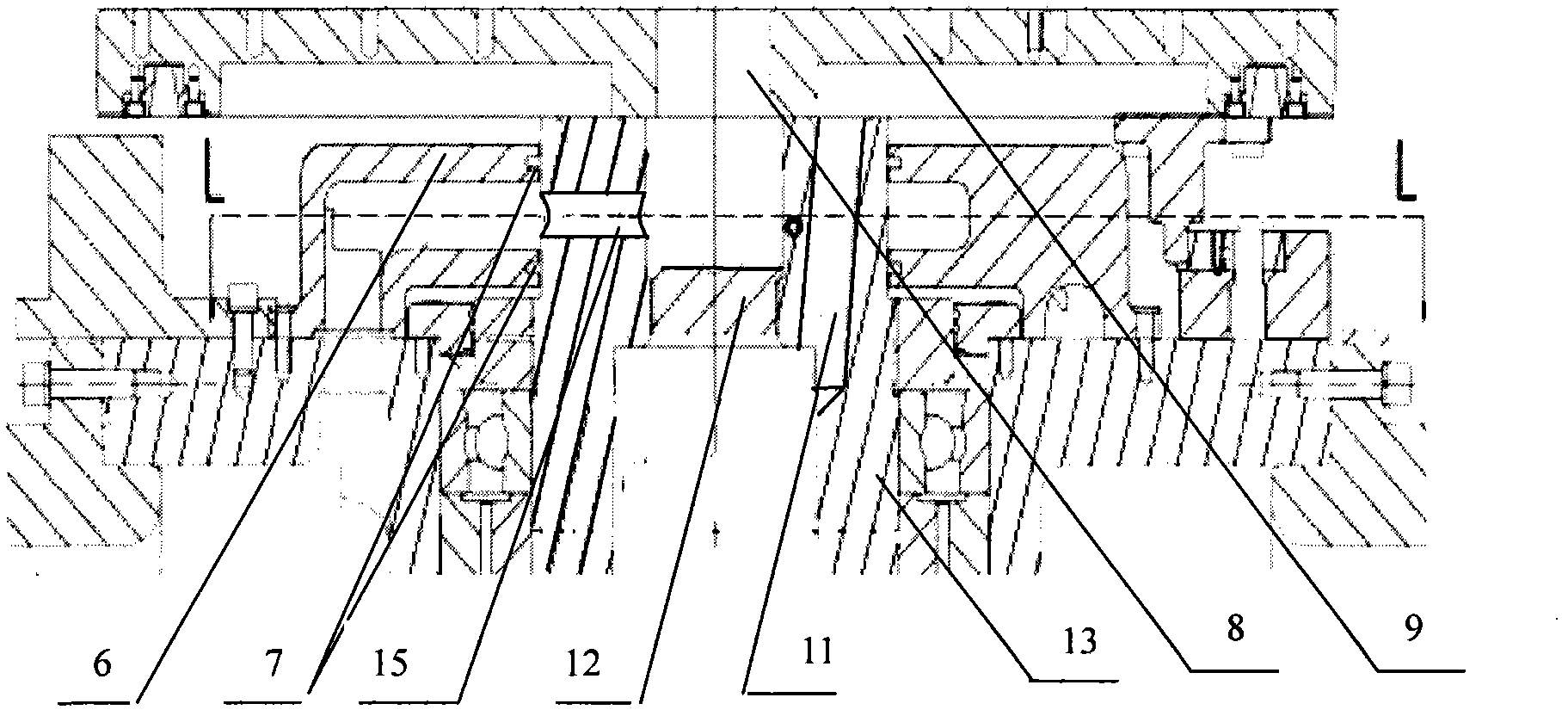

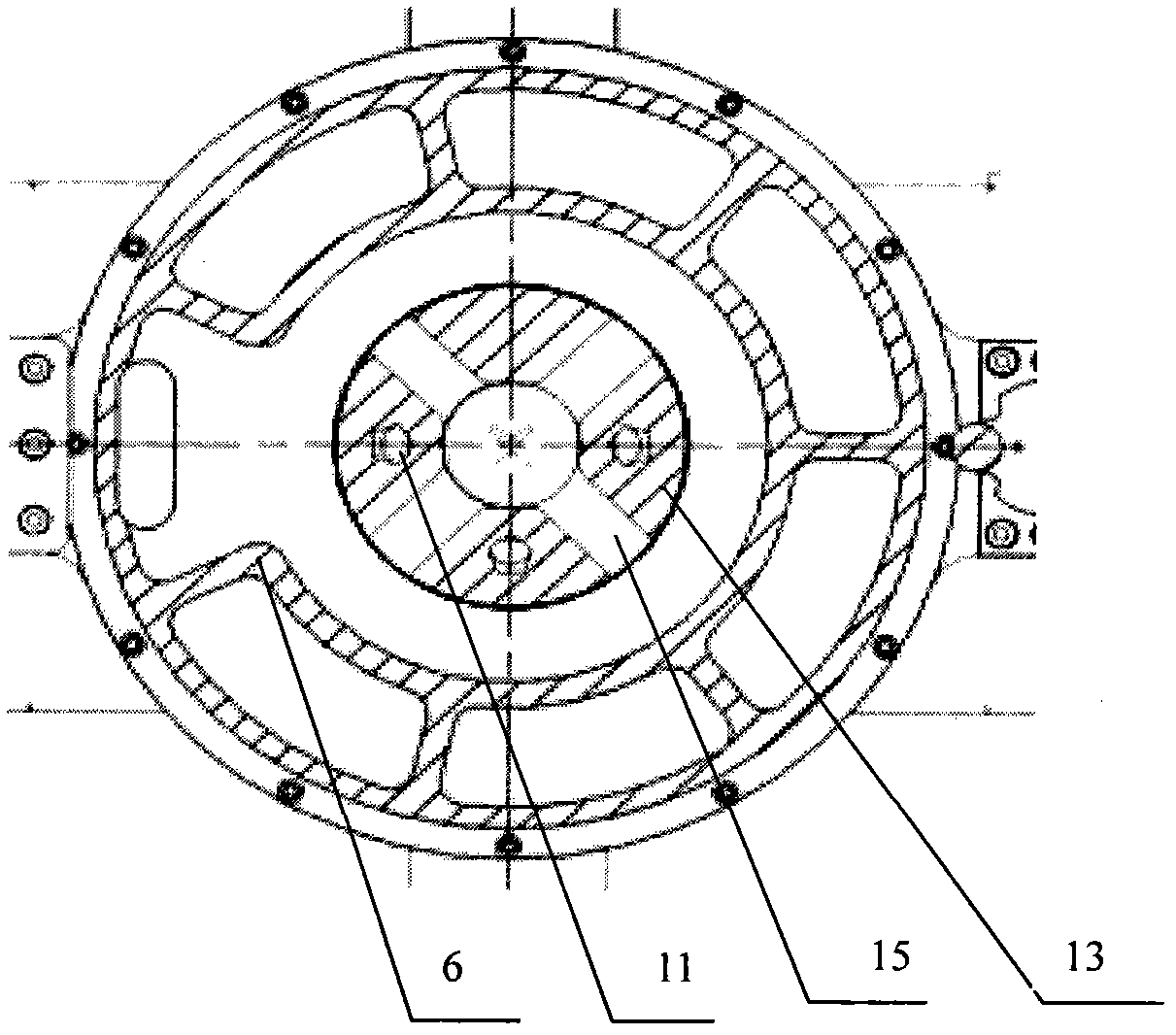

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] The external air supply pipe is connected with the air inlet 1 of the turntable, and the air volume is introduced into the built-in air duct of the turntable. The air inlet 1 is fixed on the shaft end housing 3 of the inclined shaft 4 of the turntable, and a rotating sealing ring 2 is added between the air inlet 1 and the inclined shaft 4, forming a dynamic and static connection between the air inlet 1 and the inclined shaft 4, achieving The function that the inclined shaft 4 rotates continuously while continuously supplying air. The inclined shaft 4 is a hollow structure to form an air duct. The inclined shaft 4 is connected to the housing 5 of the azimuth shaft system. The azimuth housing 5 is equipped with an annular air box 6. One end of the annular air box 6 is connected to the hollow air duct of the inclined shaft 4. In communication, the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com