Mining method for ore bed

A mining method and technology of ore seam, which are applied in surface mining, earth-moving drilling, underground mining, etc., can solve the problems of unsecured safety of mining workers, inability to collect minerals in the seam completely, and inaccessibility of machinery, etc. The effect of large working space and comprehensive cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

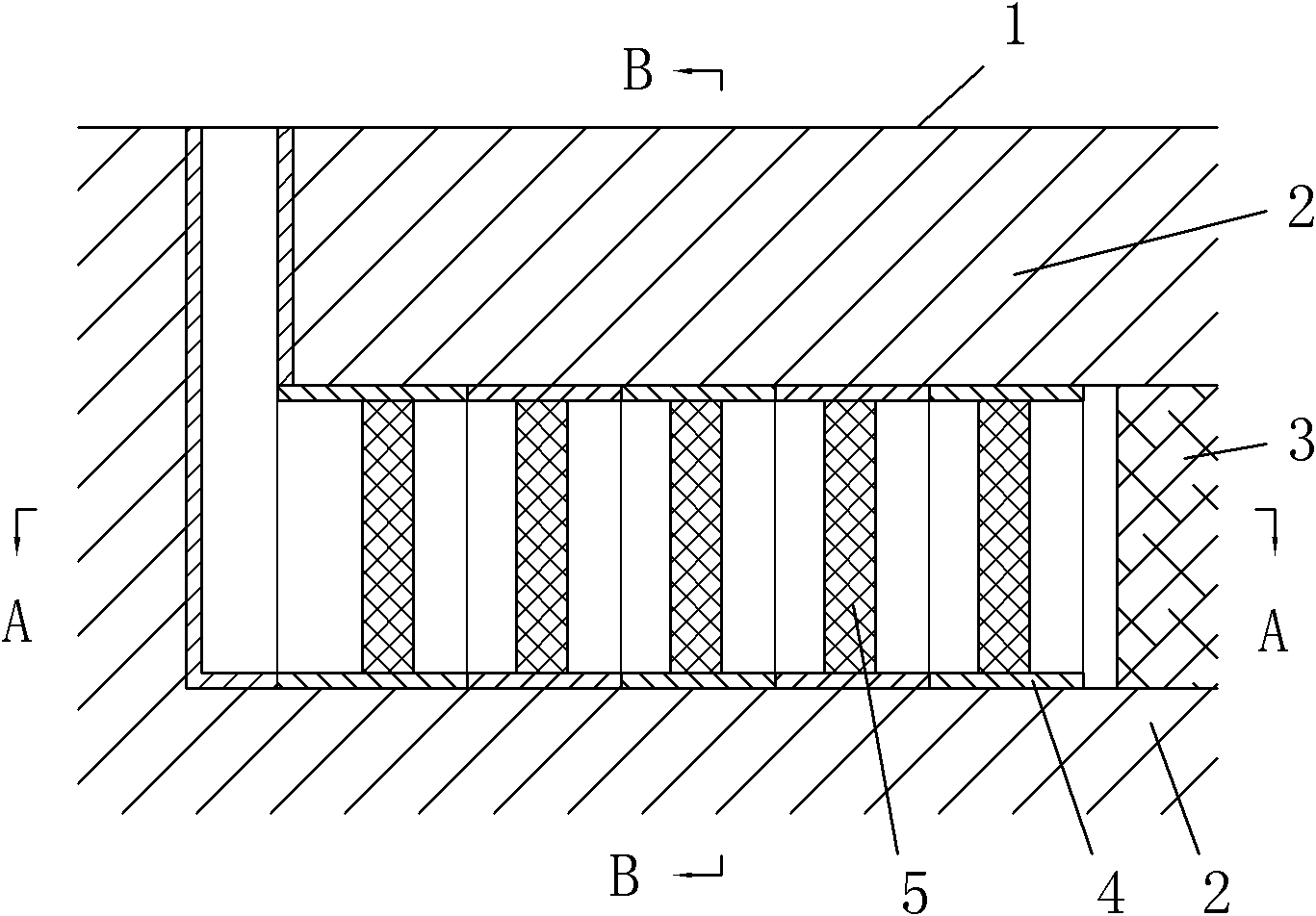

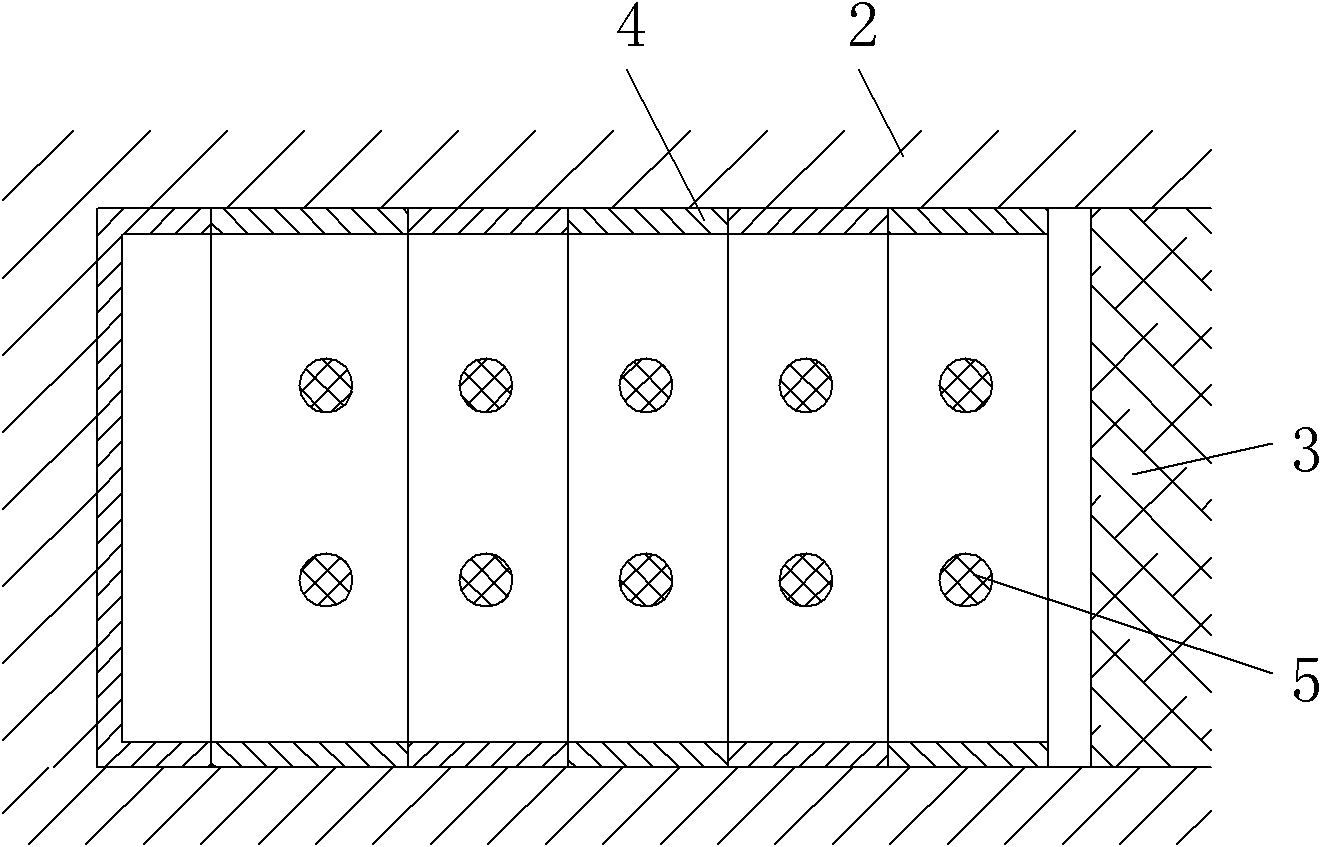

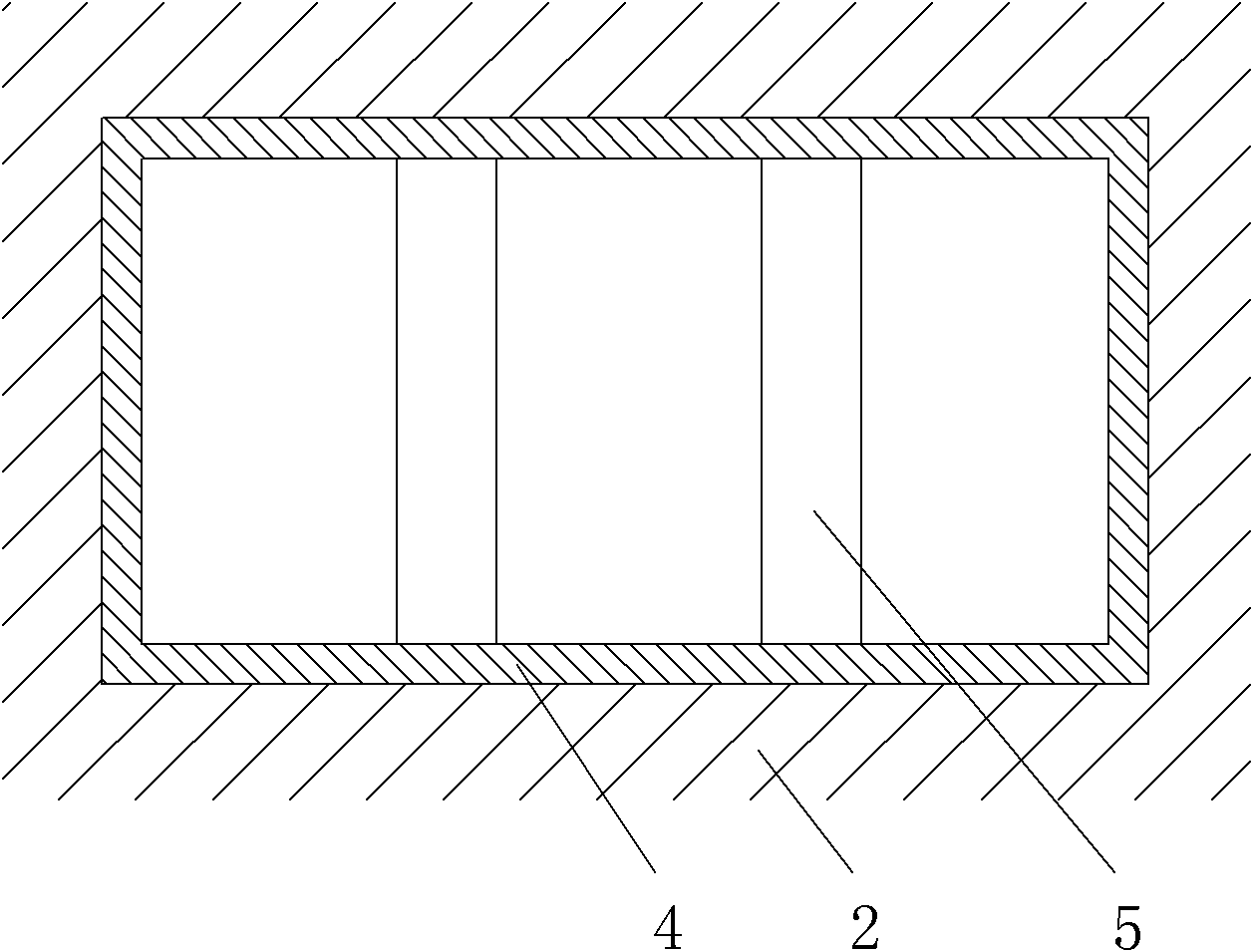

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 ;

[0018] A mining method of a mine seam adopts a large-section excavation method for mining. At the same time as mining, the four walls of the vacant mining area that has been mined are constructed with a reinforced concrete structure into an annular body 4 with four sides, up, down, left, and right. Every time a section is mined forward, the Construct a section of annular body 4, and two adjacent annular bodies 4 are constructed into an integrated structure, and vertical beams 5 for support are constructed at intervals between the upper and lower inner walls of the annular body, and the inner wall surface of the annular body 4 is treated to prevent air seepage and water leakage After the mining of the mine is completed, a mine for production or living is formed. The anti-seepage and water-proof treatment of the inner wall of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com