Construction method of piercing connection joint between steel beam/steel pipe concrete column and reinforced concrete beam

A technology for connecting joints and steel pipe concrete columns, which is applied in the direction of building construction, construction, and building material processing, etc., can solve the problems of complex force and structure, small welding volume space, and many through-hole components, and achieve welding volume space Small size, reduced steel consumption, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

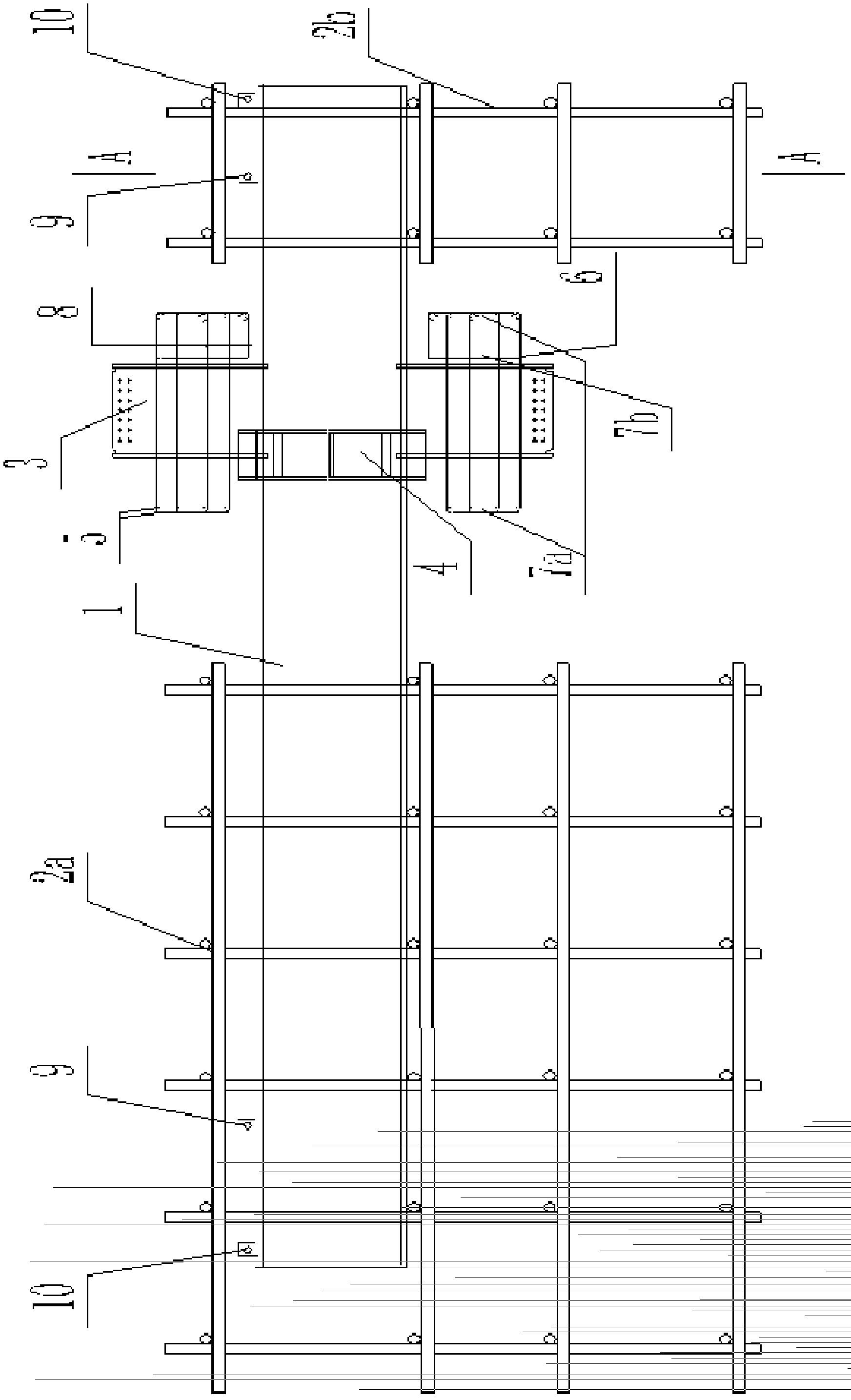

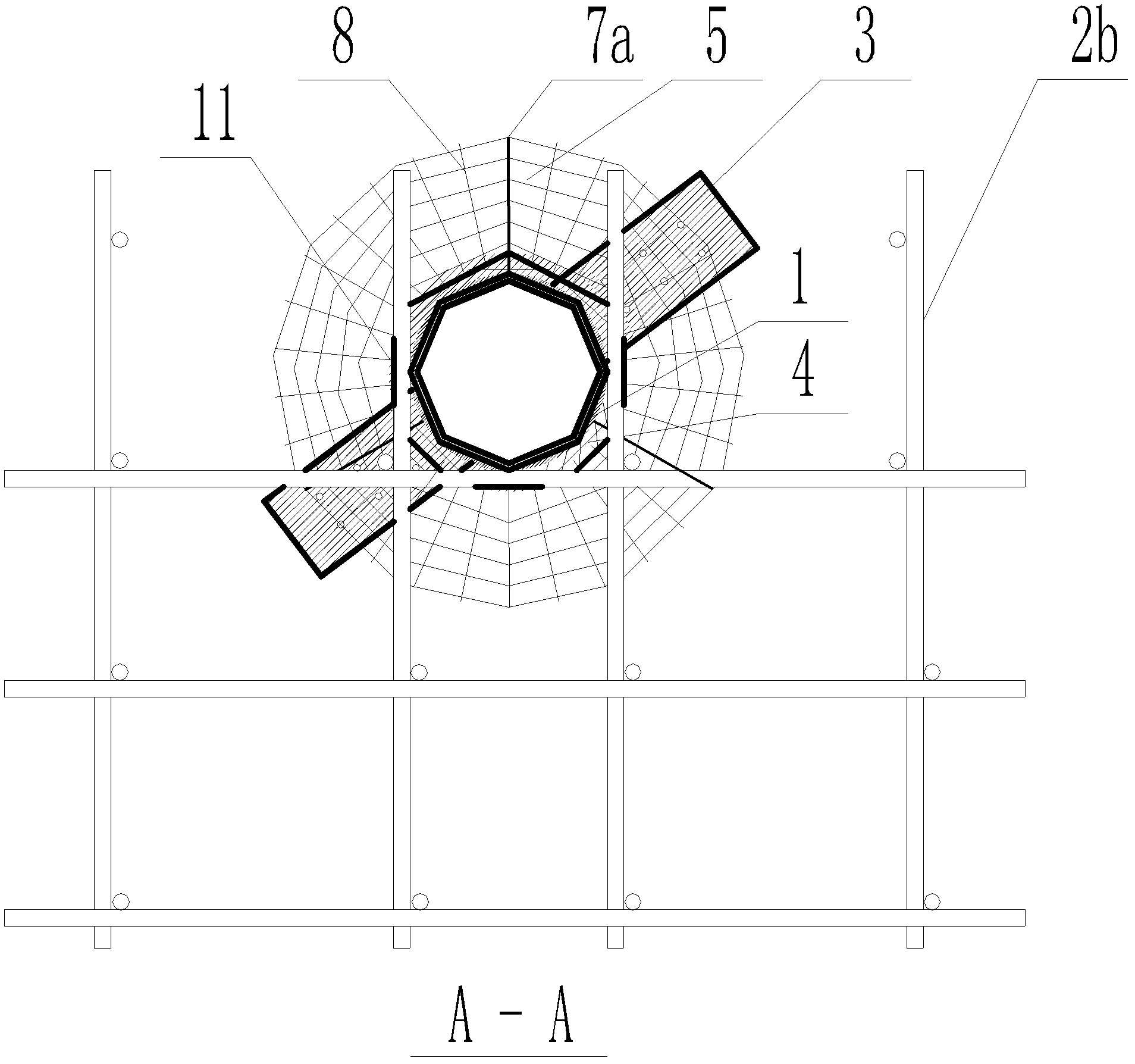

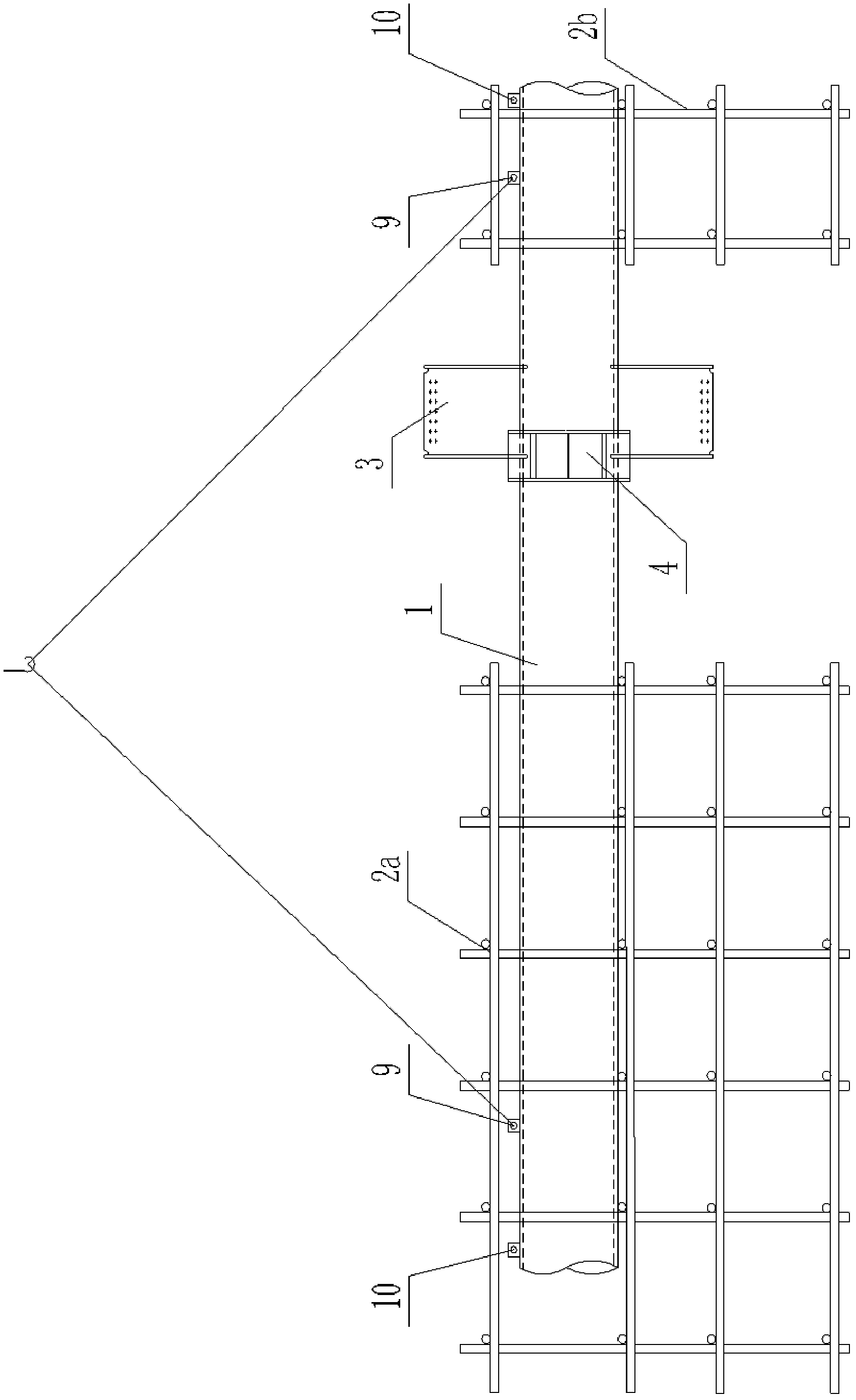

[0043] A steel beam-concrete steel pipe column and a reinforced concrete beam through-the-center connection node construction method, the steps of which are:

[0044] A. Set up a single-layer steel pipe column to support the tire frame and hoist it horizontally on the tire frame:

[0045] Take the single-layer steel pipe column beam-column node as the dividing point to deduct the beam height H of the ring beam steel corbel and the steel beam through-the-heart corbel. At the same time, the diameter D of the single-layer steel pipe column, the diameter D is 600mm ~ 1500mm, and 5mm is added to each side to determine the erection distance of the supporting tire frame vertical poles, plus the length of the span direction of the steel beam through the center of the corbel is the supporting tire frame erecting width , Complete the erection of the front and rear two supporting tire frames.

[0046] According to the position of the upper and lower main bars of the reinforced concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com