Amine lactone type amphoteric high polymer emulsion as well as preparation method and application thereof

A technology of amphoteric polymers and polymer emulsions, applied in separation methods, drilling compositions, chemical instruments and methods, etc., can solve problems such as low molecular weight and inability to increase oil recovery, and achieve simple operation and convenient application , easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

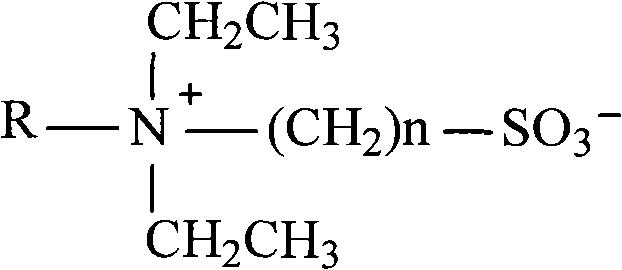

Method used

Image

Examples

Embodiment 1

[0046] Water phase: Weigh 28g of acrylamide and 3g of zwitterionic monomer DEPS (methacryloyloxyethyl-N, N'-diethyl-N-propanesulfonic acid amine salt), dissolve them in 40g of deionized water, add Contain 5 g of aqueous solution of complexing agent EDTA (ethylenediaminetetraacetic acid disodium salt) at a certain concentration, and pass nitrogen gas for 20 minutes. Oil phase: Weigh 4.5g of a compound emulsifier with an HLB value of 4.5, and mix it with 30g of white oil evenly. Under high-speed stirring, slowly add the water phase to the oil phase dropwise, and stir well to form a uniform W / O emulsion. Nitrogen deoxygenation 20min. Add 2 mL of an aqueous solution of a reducing agent and 2 mL of an aqueous solution of an oxidizing agent to the above-mentioned emulsion successively dropwise, raise the temperature to 30° C., and continue the reaction for 1 to 4 hours to obtain a milky white uniform viscous amphoteric polymer emulsion of the amino lactone type. The amphoteric pol...

Embodiment 2

[0048] Water phase: Weigh 28g of acrylamide and 6g of zwitterionic monomer (DEPS), dissolve in 40g of deionized water, add 5g of aqueous solution containing a certain concentration of complexing agent EDTA, and pass nitrogen gas for 20min. Oil phase: Weigh 4.5g of a compound emulsifier with an HLB value of 4.5, and mix it with 30g of white oil evenly. Under high-speed stirring, slowly add the water phase to the oil phase dropwise, and stir well to form a uniform W / O emulsion. Nitrogen deoxygenation 20min. Add 2 mL of an aqueous solution of a reducing agent and 2 mL of an aqueous solution of an oxidizing agent to the above-mentioned emulsion successively dropwise, raise the temperature to 30° C., and continue the reaction for 1 to 4 hours to obtain a milky white uniform viscous amphoteric polymer emulsion of the amino lactone type. The amino lactone type amphoteric polymer powder obtained after ethanol precipitation and drying has an intrinsic viscosity of 14.2 dL / g.

Embodiment 3

[0050] Water phase: Weigh 28g of acrylamide and 6g of zwitterionic monomer (DEPS), dissolve them in 40g of deionized water, add 5g of an aqueous solution containing a certain concentration of complexing agent EDTA and 2g of an aqueous solution containing a certain concentration of a molecular weight regulator, and blow nitrogen for 20 minutes . Oil phase: Weigh 4.5g of a compound emulsifier with an HLB value of 4.5, and mix it with 30g of white oil evenly. Under high-speed stirring, slowly add the water phase to the oil phase dropwise, and stir well to form a uniform W / O emulsion. Nitrogen deoxygenation 20min. Add 2 mL of an aqueous solution of a reducing agent and 2 mL of an aqueous solution of an oxidizing agent to the above-mentioned emulsion successively dropwise, raise the temperature to 30° C., and continue the reaction for 1 to 4 hours to obtain a milky white uniform viscous amphoteric polymer emulsion of the amino lactone type. The amino lactone amphoteric polymer po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com